Fiber-enhanced aerogel-polymer composite material and preparation method thereof

A composite material and fiber-reinforced technology, which is applied in the field of preparation of fiber-reinforced aerogel-polymer composite materials, can solve the problems of low grade and unsatisfactory comprehensive performance, and achieves the promotion of industrial upgrading and high durability. The effect of heat resistance and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

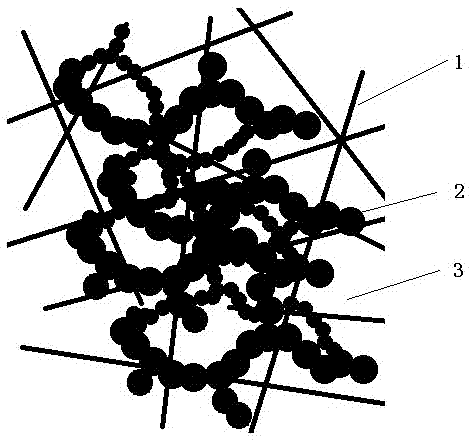

Image

Examples

Embodiment 1

[0051] According to the method of patent CN2014102703529, a glass fiber mat reinforced silica airgel board is prepared, the size of the silica airgel board is 300mm*300mm*10mm, and the density of the silica airgel is 100kg / m 3 , the average pore size is 36nm, the porosity is 90%, and the hydrophobicity is 99.8%. Polymer adopts unsaturated polyester resin, gets unsaturated polyester resin 1000g, benzoyl peroxide 8g, tert-butyl peroxybenzoate 7g is made into unsaturated polyester resin glue. The composite process adopts resin transfer molding. The glass fiber reinforced silica airgel plate is pre-laid in the closed mold cavity, the mold is locked, and the unsaturated polyester resin glue is injected into the mold cavity with pressure. After the reinforcement material is soaked Curing at room temperature, and then demoulding to form a composite material.

Embodiment 2

[0053] According to the method of patent CN2015102953891, the carbon fiber unidirectional cloth reinforced silica-titania airgel cloth is prepared, and the size of the silica-titania airgel cloth is 300mm*300mm*2mm, wherein the silica-titania airgel cloth The density is 80kg / m 3 , the average pore size is 45nm, the porosity is 93%, and the hydrophobicity is 99.8%. The polymer adopts epoxy resin, take bisphenol A type epoxy resin E-54 --- 700g; polyethersulfone (PES) --- 100g; maleic rosin --- 250g, mix and heat to 55 ° C, keep warm for 1 hour, to get epoxy resin glue. Vacuum bag / autoclave forming process is used to lay carbon fiber unidirectional cloth reinforced silica-titania airgel cloth in the mold, and the upper layer is laid with diversion net and diversion tube, and then the bag is made and sealed to make the interior in a vacuum And generate negative pressure to eliminate air bubbles, then introduce epoxy resin glue, and obtain carbon fiber unidirectional fabric rein...

Embodiment 3

[0055] According to the method of patent CN2015102953891, the zirconia airgel sheet is reinforced with basalt fiber cloth, the size of the zirconia airgel sheet is 200mm*200mm*1mm, and the density of the zirconia airgel is 110kg / m 3 , the average pore size is 32nm, the porosity is 90%, and the hydrophobicity is 99.8%. Polymer adopts phenolic resin, take phenolic resin 450g, hexamethylenetetramine 40g, polystyrene 67g, mix and stir to obtain phenolic resin glue. Using the winding molding process, the basalt fiber cloth reinforced zirconia airgel cloth tape impregnated with phenolic resin glue is wound on the mandrel according to certain rules, and then solidified and demoulded to become a composite material. Sand and paint the cured composite material.

[0056] Table 1 Test data of fiber reinforced airgel-polymer composites

[0057] serial number

[0058] Note: The comparison item is the composite material obtained by using the same type of fiber and polymer and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com