Solid powder cosmetic

A technology of solid powder and cosmetics, applied in the field of solid powder cosmetics, which can solve problems such as dark color and lack of effectiveness of boron nitride, and achieve excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

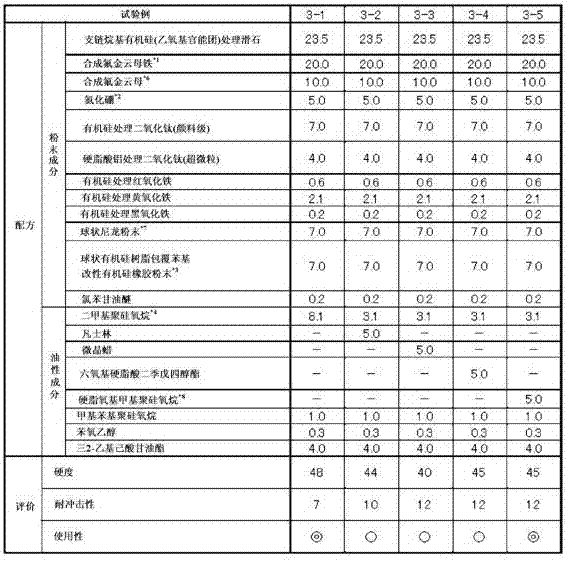

Examples

Embodiment

[0101] Examples and the like according to the present invention will be described below, but the present invention is not limited thereto. It should be noted that the amounts in the following formulations are % by mass.

[0102] First, the manufacturing method and evaluation method of the cosmetic used in the Example are demonstrated.

[0103]

[0104]The powder components described in the formulations in the following tables and the oily components heated and melted as needed were mixed using a Henschel mixer, and then pulverized using a pulverizer to obtain a uniform mixture. An equal amount of water (=volatile dispersion medium) was added to this mixture, and mixed using DISPERMIX to obtain a slurry. This slurry was filled in a medium pan, and the solvent was removed by suction, followed by drying to obtain a solid powder cosmetic.

[0105]

[0106] (A) Impact resistance

[0107] The solid powder cosmetic was placed in a compact container for cosmetics, dropped onto ...

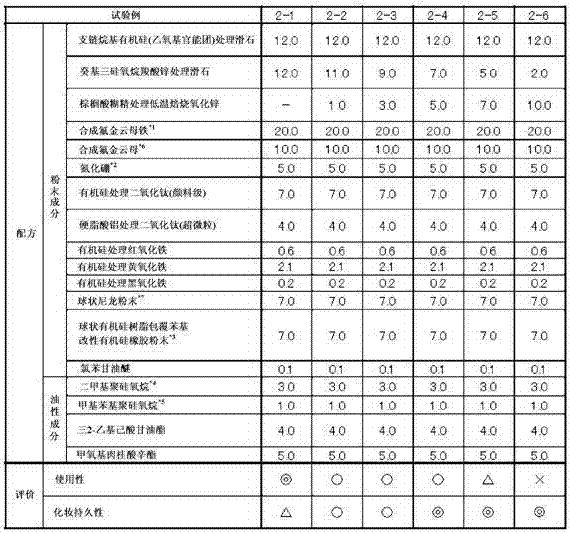

Embodiment 2

[0161] Example 2: Powder Foundation

[0162]

[0163] Composition Combination amount (mass %)

[0164] (1) Carboxylic silicone soap treated talc Balance

[0165] (2) Synthesis of fluorine phlogopite iron *1 15.0

[0166] (3) Synthetic Fluorphlogopite *6 10.0

[0168] (5) Boron nitride *2 5.0

[0169] (6) Aluminum stearate treated microparticle titanium oxide 4.0

[0170] (7) Low-temperature roasted zinc oxide treated with palmitate dextrin 2.0

[0171] (8) Silicone treated titanium oxide 10.0

[0172] (9) Organosilicon treated red iron oxide 0.2

[0173] (10) Silicone-treated yellow iron oxide 1.4

[0174] (11) Organosilicon treated black iron oxide 2.0

[0175] (12) spherical nylon powder *7 6.0

[0176] (13) Spherical silicone resin coated phenyl modified silicone rubber powder *3 8.0

[0177] (14) Spherical polyurethane powder *9 3.0

[0178] (15) Chlorphenesin 0.2

[0179] (16) Dimethicone *4 2.0

[0180] (17) Phenyl tr...

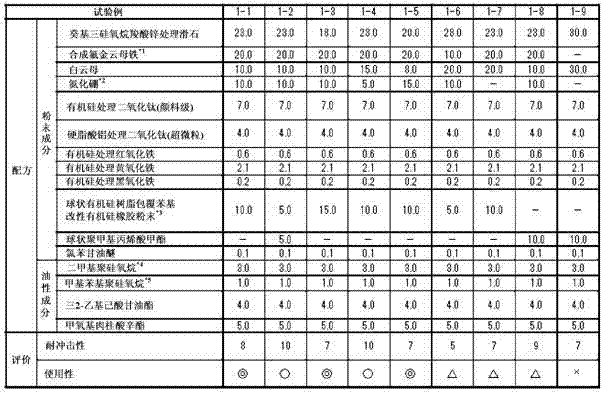

Embodiment 3

[0187] Example 3: Powder Foundation

[0188] Composition Combination amount (mass %)

[0189] (1) Carboxylic silicone soap treated talc Balance

[0190] (2) Synthesis of fluorine phlogopite iron *1 15.0

[0191] (3) Organosilicon treatment to synthesize fluorine phlogopite 10.0

[0192] (4) Glass sheet 5.0

[0193] (5) Boron nitride *2 5.0

[0194] (6) Aluminum stearate treated microparticle titanium oxide 4.0

[0195] (7) Low-temperature roasted zinc oxide treated with palmitate dextrin 2.0

[0196] (8) Silicone treated titanium oxide 10.0

[0197] (9) Organosilicon treated red iron oxide 0.2

[0198] (10) Silicone treated yellow iron oxide 1.4

[0199] (11) Organosilicon treated black iron oxide 2.0

[0200] (12) spherical nylon powder *7 6.0

[0201] (13) Spherical silicone resin coated phenyl modified silicone rubber powder *3 8.0

[0202] (14) Spherical polyurethane powder *9 3.0

[0203] (15) Methyl p-hydroxybenzoate 0.2

[0204] (16) Dimethicone *4 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com