Perovskite solar cell-supercapacitor integrated device and preparation method of the same

A technology for solar cells and supercapacitors, which is applied in the manufacture of hybrid/electric double layer capacitors, capacitors, hybrid capacitor electrodes, etc., can solve problems such as the inability to apply flexible electronic products, and is beneficial to packaging and use, simplifies the preparation process, and increases The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

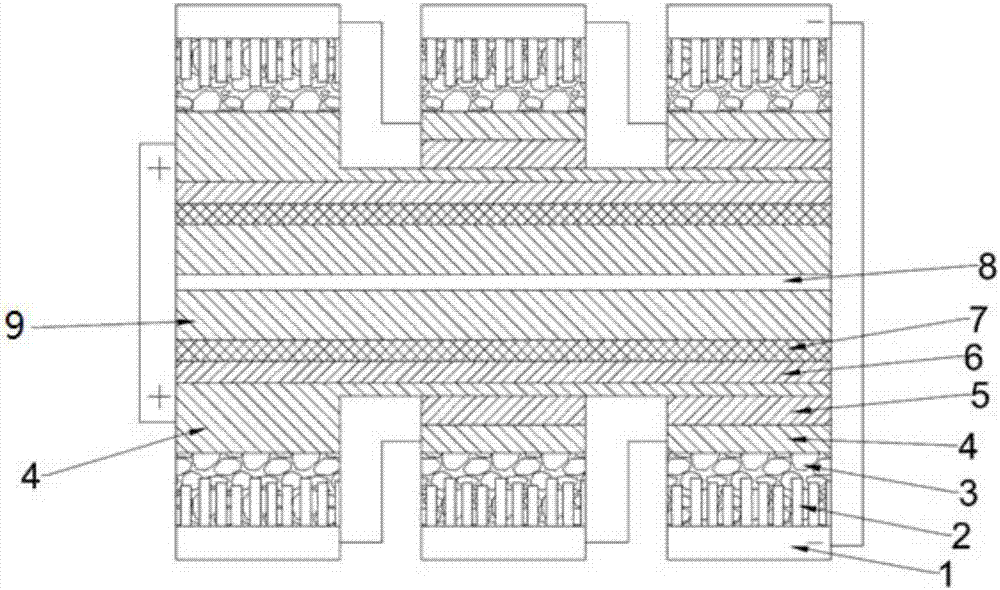

[0055] According to another aspect of the present invention, there is also provided a method for preparing a solar cell-supercapacitor integrated device, comprising the following steps:

[0056] 1) Pretreatment of the flexible conductive substrate 1: ultrasonic cleaning with acetone and ethanol for 15 to 20 minutes respectively to remove organic matter on the surface of the substrate, then cleaning with deionized water, and finally putting it into an ultraviolet ozone cleaner for 30 to 40 minutes carry out surface modification;

[0057] 2) growing by hydrothermal method, preparing CdS nanorods on the flexible conductive substrate 1 pretreated in step 1) as the photoanode 2 of the perovskite solar cell;

[0058] 3) Spin-coat PbBr on the photoanode 2 prepared in step 2) 2 solution, thereby forming a perovskite layer;

[0059] 4) Printing conductive carbon paste on the perovskite layer prepared in step 3) to prepare the first carbon counter electrode layer 4;

[0060] 5) Soak ...

Embodiment 1

[0068] Step 1: Clean the cut PET film coated with FTO ultrasonically with acetone and ethanol for 15 minutes to remove organic matter on the surface, then wash it with deionized water, and finally put it in a UV ozone cleaner for 30 minutes to clean the surface. modified;

[0069] Step 2: Take 1mmol / L cadmium nitrate Cd(NO 3 ) 2 4H 2 O, 3mmol / L thiourea and 0.6mmol / L glutathione were made into hydrothermal growth solution, and the FTO-coated side of the PET film after etching was placed vertically downward in a special stainless steel autoclave containing hydrothermal growth solution. On the bottom of the Flon liner, hydrothermal growth of CdS rods was carried out at a growth temperature of 200 °C and a growth time of 4 h. Afterwards, ultraviolet ozone treatment 10min;

[0070] Step 3: Spin-coat 1M PbBr on the surface of the photoanode 2 prepared in step 2 2 solution, the solvent is dimethylformamide (DMF), and then dried at 80°C for 20min;

[0071] Step 4: PbBr prepared...

Embodiment 2

[0079] Step 1: Clean the cut PET film coated with FTO ultrasonically for 17 minutes with acetone and ethanol respectively to remove organic matter on the surface, then wash it with deionized water, and finally put it in a UV ozone cleaning machine for 35 minutes to clean the surface. modified;

[0080] Step 2: Take 1mmol / L cadmium nitrate Cd(NO 3 ) 2 4H 2 O, 3mmol / L thiourea and 0.6mmol / L glutathione were made into hydrothermal growth solution, and the FTO-coated side of the PET film after etching was placed vertically downward in a special stainless steel autoclave containing hydrothermal growth solution. On the bottom of the Flon liner, hydrothermal growth of CdS rods was carried out at a growth temperature of 190 °C and a growth time of 4 h. Afterwards, ultraviolet ozone treatment 10min;

[0081] Step 3: Spin-coat 1M PbBr on the surface of the photoanode 2 prepared in step 2 2 solution, the solvent is dimethylformamide (DMF), and then dried at 80°C for 20min;

[0082]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com