Method for preparing ZnO ceramic film low-voltage piezoresistor

A technology of varistors and ceramic thin films, which is applied in the fields of varistors, varistor cores, and resistance manufacturing. Easy film thickness control, fast film formation, low temperature preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

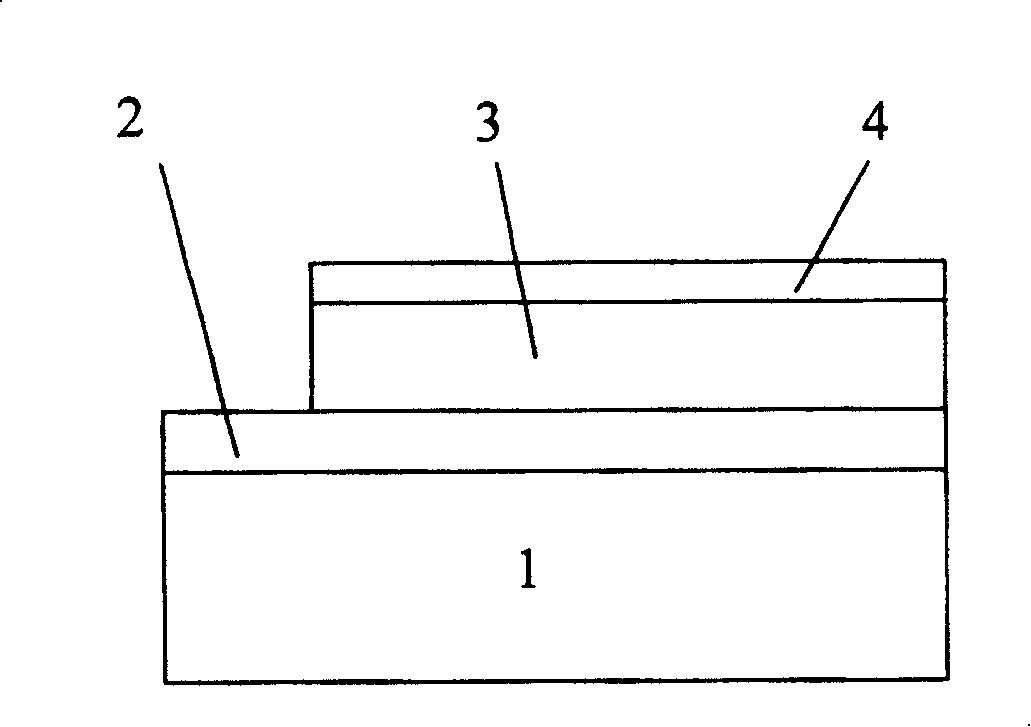

[0014] Embodiment 1 A kind of preparation method of ZnO ceramic film low voltage varistor, comprising

[0015] (1) Prepare ZnO sol according to the usual method: take 5.4 grams (0.0247mol) of zinc acetate Zn (CH 3 COO) 2 2H 2 Dissolve 0 in 10-12 ml of ethylene glycol methyl ether, add 1-2 ml of glacial acetic acid, 1-2 ml of ethanolamine, and stir for 3-4 hours at 50°C-60°C to form a stable and transparent sol;

[0016] In the above sol, doped bismuth ions Bi 3+ , antimony ion Sb 3+ , manganese ion Mn 2+ , chromium ion Cr 3+ and cobalt ion Co 3+ , press Zn 2+ : Bi 3+ :Sb 3+ :Mn 2+ :Cr 3+ :Co 3+ =100:0.6:2.0:1.0:0.5:1.0 molar ratio, bismuth nitrate Bi(NO 3 ) 3 , antimony chloride SbCl 3 , manganese acetate Mn(CH 3 COO) 2 , chromium nitrate Cr(NO 3 ) 3 and cobalt nitrate Co(NO 3 ) 3 , forming a uniform and stable sol;

[0017] (2) Take 60% of the above sol, dry it first, then slowly heat up to 650°C to decompose the organic matter, and then grind it to prep...

Embodiment 2

[0020] Embodiment 2 A kind of preparation method of ZnO ceramic film low-voltage varistor, comprising

[0021] (1) prepare ZnO sol by usual method;

[0022] In the above sol, doped bismuth ions Bi 3+ , antimony ion Sb 3+ , manganese ion Mn 2+ , chromium ion Cr 3+ and cobalt ion Co 3+ , press Zn 2+ : Bi 3+ :Sb 3+ :Mn 2+ :Cr 3+ :Co 3+ =100:1.4:1.6:0.6:3.0:2.0 molar ratio, bismuth chloride BiCl can be added 3 , antimony acetate Sb(CH 3 COO) 3 , manganese nitrate Mn(NO 3 ) 2 , chromium acetate Cr(CH 3 COO) 3 and cobalt acetate Co(CH 3 COO) 3 , forming a uniform and stable sol;

[0023] (2) Take 70% of the above sol, dry it first, then slowly heat up to 600°C to decompose the organic matter, and then grind it to prepare ZnO nanopowder with a particle size of 30nm to 70nm;

[0024] (3) with (3) in embodiment 1;

[0025] (4) Change the annealing temperature of the thin film 3 described in (4) in Example 1 to 750° C., and the others are the same as (4) in Example ...

Embodiment 3

[0026] Embodiment 3 A kind of preparation method of ZnO ceramic film low voltage varistor, comprising

[0027] (1) prepare ZnO sol by usual method;

[0028] In the above sol, doped bismuth ions Bi 3+ , antimony ion Sb 3+ , manganese ion Mn 2+ , chromium ion Cr 3+ and cobalt ion Co 3+ , press Zn 2+ : Bi 3+ :Sb 3+ :Mn 2+ :Cr 3+ :Co 3+ =100:1.0:3.0:0.2:2.0:3.0 molar ratio, bismuth nitrate Bi(NO 3 ) 3 , antimony chloride SbCl 3 , manganese acetate Mn(CH 3 COO) 2 , chromium acetate Cr(CH 3 COO) 3 and cobalt acetate Co(CH 3 COO) 3 , forming a uniform and stable sol;

[0029] (2) Take 80% of the above sol, dry it first, and then slowly heat up to 550°C to decompose the organic matter, and then grind it to prepare ZnO nanopowder with a particle size of 30nm to 70nm;

[0030] (3) with (3) in embodiment 1;

[0031] (4) Change the annealing temperature of the thin film 3 described in (4) in Example 1 to 850° C., and the others are the same as (4) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com