A kind of aerospace optical cable and preparation method thereof

A technology for aerospace and optical cables, which is applied in the field of ultra-light optical cables for communication. It can solve problems such as the performance degradation of optical fibers and outer sheath materials, the failure of optical cables to meet the application occasions, and the inability to guarantee the operation of optical cables. It achieves fast curing speed and light weight. , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

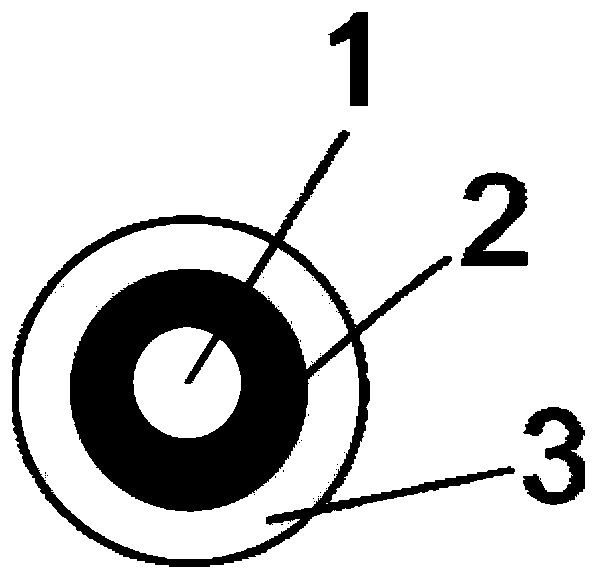

[0040] An aerospace optical cable, the structure of which is as follows figure 1 As mentioned above, it includes optical fiber, acrylate coating, thermoplastic polyurethane elastomer (TPU) layer 2, aramid fiber braiding layer 3 from the inside to the outside, the thickness of the acrylate coating is 50 μm, and the thickness of the thermoplastic polyurethane elastomer (TPU) layer The thickness is 0.15mm, and the thickness of the aramid fiber braided layer is 0.2mm. The acrylate coating includes an inner coating layer and an outer coating layer, the inner coating layer is a low modulus resin material, the outer coating is a high modulus resin material, the thickness of the inner coating layer is 20 μm, and the outer coating layer is 30 μm . The low modulus resin has a modulus of 80MPa, and the high modulus resin has a modulus of 150MPa. The low modulus resin and the high modulus resin are acrylates.

[0041] The raw material of the polyethersulfone tight sleeve layer is polye...

Embodiment 2

[0049] An aerospace optical cable, the structure of which is as follows figure 1 As mentioned above, it includes optical fiber, acrylate coating, polyethersulfone tight sleeve layer 2, and aramid fiber braiding layer 3 from inside to outside. The thickness of the acrylate coating is 60 μm, and the thickness of the polyethersulfone tight sleeve layer is 0.10 mm. , The thickness of the aramid fiber braided layer is 0.4mm. The acrylate coating includes an inner coating layer and an outer coating layer, the inner coating layer is a low modulus resin material, the outer coating layer is a high modulus resin material, the thickness of the inner coating layer is 30 μm, and the outer coating layer is 30 μm . The low modulus resin has a modulus of 80MPa, and the high modulus resin has a modulus of 150MPa. The low modulus resin and the high modulus resin are acrylates.

[0050] The raw material of the polyethersulfone tight sleeve layer is polyethersulfone, which is prepared by conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com