Floor cable and preparation method thereof

A cable and floor technology, which is applied in the field of floor cables and its preparation, can solve problems such as falling pedestrians, construction troubles, electric shock accidents, etc., and achieve the effects of prolonging service life, low production cost, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

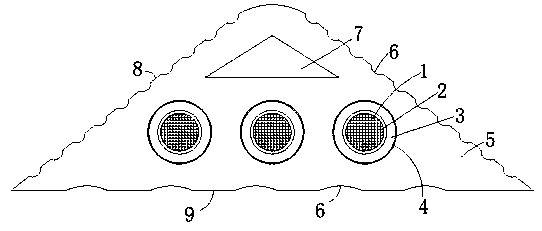

[0028] Embodiments of the present invention are described in detail by the following specific embodiments, and the examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or elements with the same or similar functions; The embodiments described with reference to the figures are exemplary, and are intended to explain the present invention, and should not be construed as limiting the present invention.

[0029] Referring to 1, a preparation method for floor cables, comprising the steps:

[0030] Step A: Twisting the thin monofilament bundles into strands, and then re-twisting the multi-strand wires to form a conductor;

[0031] Step B: longitudinally wrap at least one layer of release paper on the conductor to form an inner isolation layer 2;

[0032] Step C: extruding ethylene-propylene rubber on the release paper to form the insulating layer 3;

[0033] Step D: Wrap polyester ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com