Ceramic material, sintered ceramics and component made therefrom, production method, and use of the ceramics

A ceramic material, sintered ceramic technology, applied in electrical components, parts of fixed capacitors, thin material processing, etc., can solve problems such as unfavorable integration of inductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

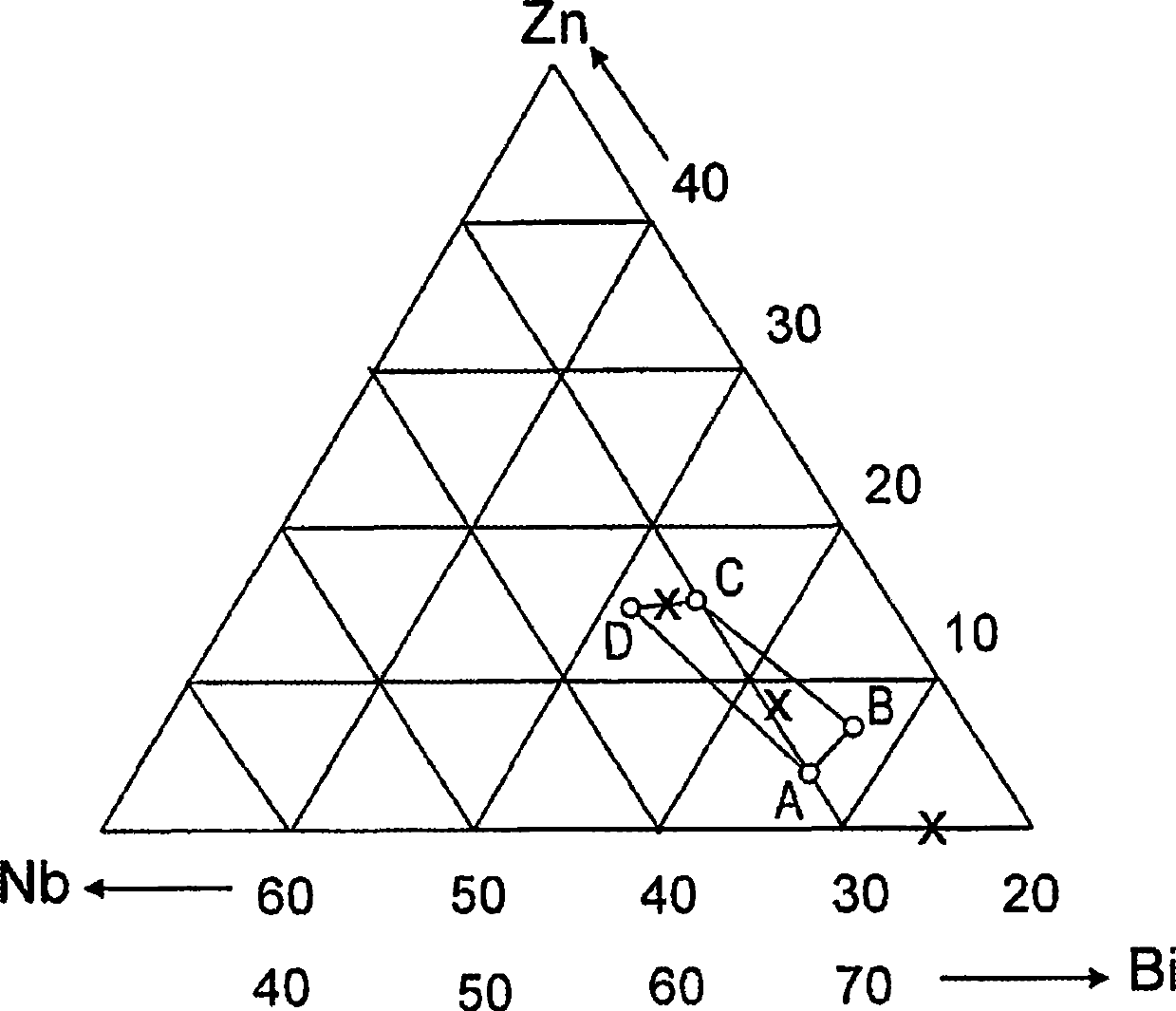

[0035] figure 1 represents the ZnO-BiO 1,5 -NbO 2,5 Part of a three-phase diagram. In the phase diagram, a quadrangle is formed by four points A to D, and in the quadrangle, each point in the plane enclosed by these points represents a composition of a ceramic according to the invention with favorable properties Element. The coordinates of the different points A, B, C and D expressed in mole percent are as follows:

[0036] A: Zn=4.0; NbO 2,5 = 30.0; BiO 1,5 =66.0

[0037] B: Zn=7.8; Nb=25.0; Bi=67.2

[0038] C: Zn=16.0; Nb=30.0; Bi=54.0

[0039] D: Zn=15.0; Nb=35.0; Bi=50.0

[0040] In addition, three components are marked with X and lie on a line in the phase diagram. The two outer points consist of the two pure phases A or B. Points in the middle of the line correspond to a 1:1 composition of the two pure phases. This embodiment has near-optimal performance, which makes sintered ceramics well suited for use in electrical components in which a capacitor and / or an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com