Water-proof inflammable coal ash/metakaolin-based insulation board

A technology of metakaolin and fly ash, which is applied in the field of production of fly ash/metakaolin-based insulation boards, can solve the problems of continuous process production of limited materials, increase of production cost, long demoulding time, etc., and achieve hydration reaction Efficiency improvement, cost saving, good thermal insulation coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

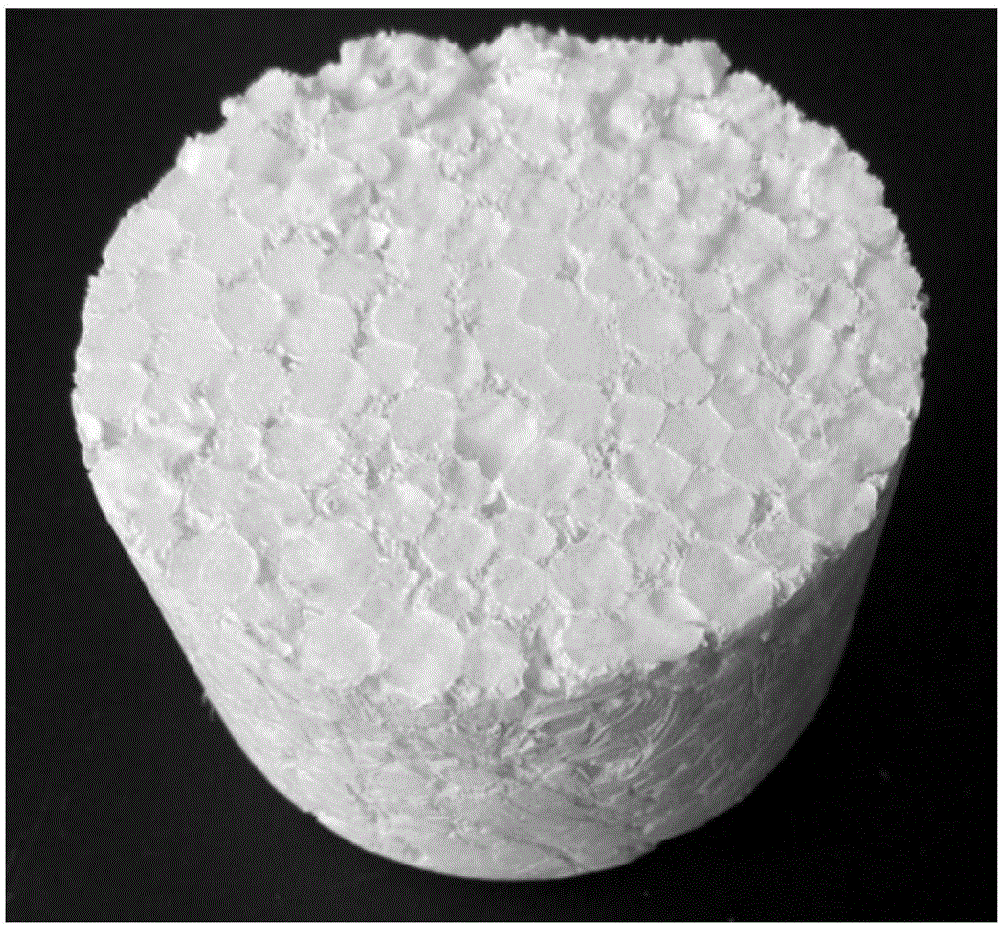

Image

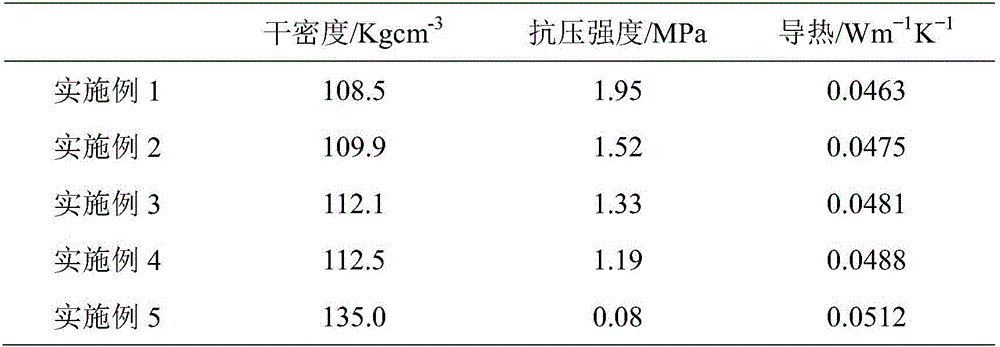

Examples

preparation example Construction

[0041] In step 1) of the preparation method according to the present invention, since the cost of metakaolin is relatively high, and the cost of fly ash is low, the strength is poor when used alone. Therefore, in the present invention, metakaolin and fly ash are used in combination as Insulation board aggregate. Uncalcined kaolin has low activity, and the material prepared after mixing with alkali stimulant has poor strength and other properties, and cannot be used in actual applications. Therefore, the metakaolin in the present invention is calcining the kaolin at a certain temperature for a period of time to improve the activity of the kaolin, thereby obtaining a metakaolin with higher activity. In step 1), in order to ensure the higher activity of the aggregate, the kaolin is calcined at a temperature of 600°C to 900°C for 1h to 5h. The fly ash is obtained directly from the power plant without calcination.

[0042] The geopolymer aggregate can be selected from one or a mixtu...

Embodiment 1

[0048] Weigh 12.1584g of sodium silicate water glass solution in a plastic flask, weigh 2.4650g of sodium hydroxide into 4.7176g of water and stir to dissolve, then add it to sodium silicate water glass and mix evenly to obtain an alkali activator. Set aside. Weigh 3.4680g fly ash and 8.0920g metakaolin (3:7) as aggregates, weigh 0.2312g aluminum powder as blowing agent, 0.6990g calcium sulfate as reinforcing agent, and weigh 0.4626g glass fiber as toughening agent , 0.5020g sodium methyl silicate as a waterproofing agent, weigh 0.0115g calcium stearate as a foam stabilizer, 0.4200g alumina as a coagulant, and mix and stir the above dry powder evenly. Then the alkali stimulator is added to the aggregate, and the mixture is stirred rapidly for 30 seconds at a speed of 3000 rpm. Continue to stir to get a viscous slurry, let it stand at room temperature for 20 minutes, until the aggregate and the alkali stimulant fully contact and react.

[0049] Weigh 2.4000g of EVA emulsion and ...

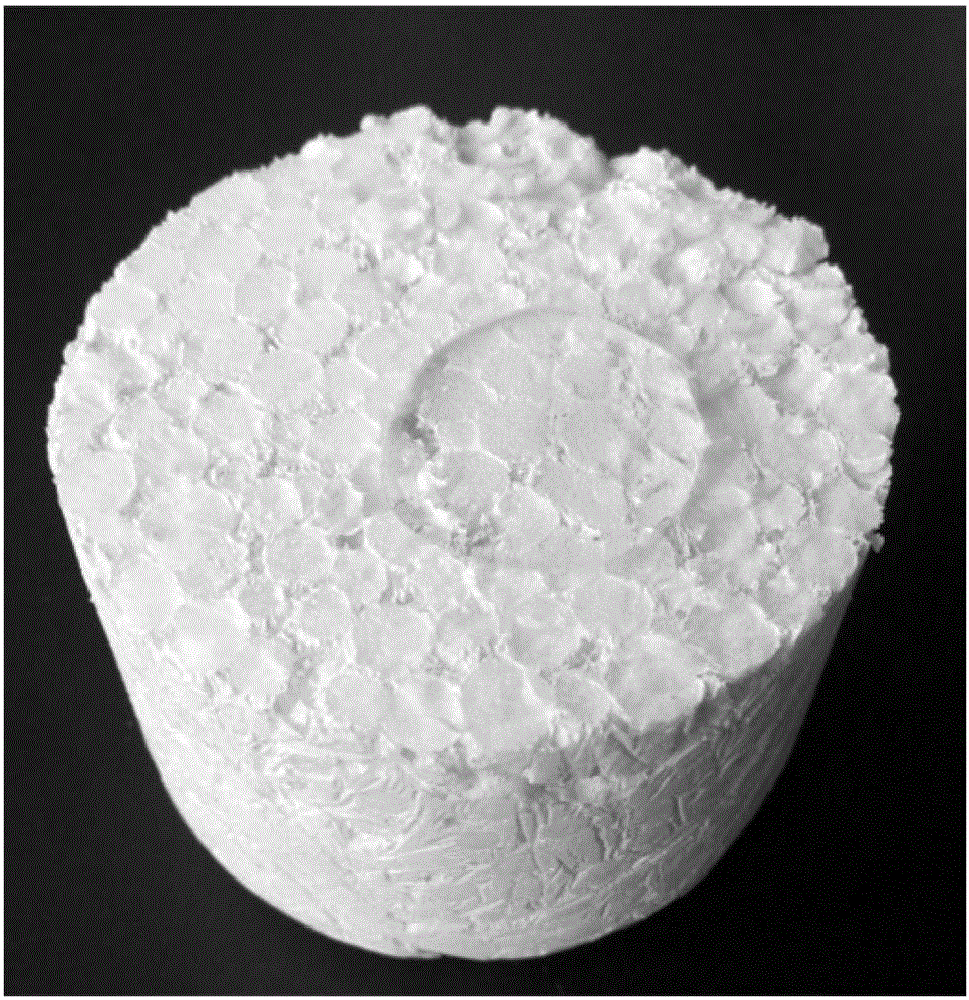

Embodiment 2

[0051] Weigh 12.1584g of sodium silicate water glass solution in a plastic flask, weigh 2.4650g of sodium hydroxide into 4.7176g of water and stir to dissolve, then add it to sodium silicate water glass and mix evenly to obtain an alkali activator. Set aside. Weigh 4.6240g fly ash and 6.9360g metakaolin (4:6) as aggregates, weigh 0.2312g aluminum powder as foaming agent, 0.6990g calcium sulfate as reinforcing agent, and weigh 0.4626g glass fiber as toughening agent , 0.5020g sodium methyl silicate as a waterproofing agent, weigh 0.0115g calcium stearate as a foam stabilizer, 0.4200g alumina as a coagulant, and mix and stir the above dry powder evenly. Then the alkali stimulator is added to the aggregate, and the mixture is stirred rapidly for 30 seconds at a speed of 3000 rpm. Continue to stir to get a viscous slurry, let it stand at room temperature for 20 minutes, until the aggregate and the alkali stimulant fully contact and react.

[0052] Weigh 2.4000g of EVA emulsion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com