Anti-corrosion waterborne epoxy static electricity conducting paint and preparation method and application thereof

A water-based epoxy resin and epoxy conductive technology, which is applied in the direction of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of affecting the quality of oil products, poor medium resistance, dark color, etc., to eliminate construction risks, The effect of eliminating health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

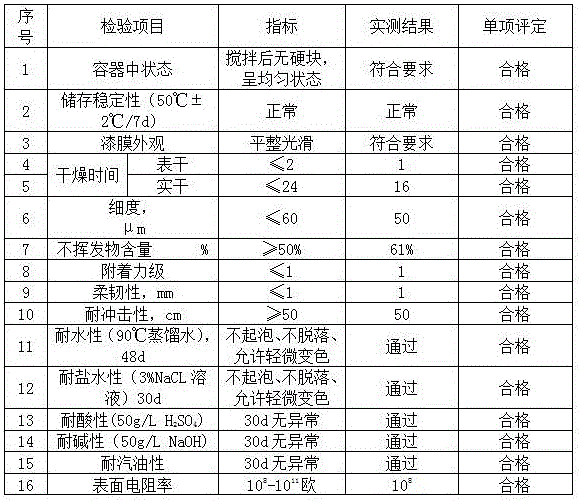

Embodiment 1

[0031] (1) After premixing 8 parts by weight of water and 0.4 parts by weight of water-based dispersant, add 15 parts by weight of water-based epoxy resin emulsion, stir until uniform, and gradually add 1.0 parts by weight of bentonite and 9 parts by weight of talc in the following order Powder, 12 parts by weight of precipitated barium sulfate, and 8 parts by weight of titanium dioxide are uniformly dispersed at a high speed to a sand mill, and ground to a fineness of less than 50 microns;

[0032] Then add 15 parts by weight of water-based epoxy resin emulsion, 24 parts by weight of conductive powder and stir evenly, add 0.2 parts by weight of water-based wetting agent, stir evenly, and gradually add 0.3 parts by weight of defoamer and 0.3 parts by weight of leveling agent and 0.5 parts by weight of anti-flash rust agent.

[0033] Add 10 parts by weight of 1.0 parts by weight water-based thixotropic agent diluted according to the proportion, stir evenly, add 2 parts by weigh...

Embodiment 2

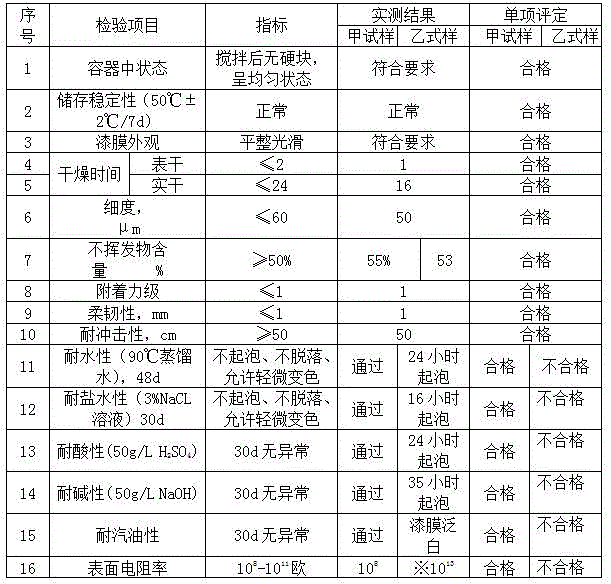

[0039] Embodiment 2 (comparative test)

[0040](1) After premixing 10 parts by weight of water and 0.4 parts by weight of water-based dispersant, add 18 parts by weight of water-based epoxy emulsion (among them, model A adopts 703A water-based epoxy resin emulsion from Shanghai Xinhua Resin Factory, and model B adopts the market In the external emulsification type water-based epoxy emulsion sold by other manufacturers), stir until uniform, and gradually add 1.0 parts by weight of bentonite, 10 parts by weight of talc powder, 10 parts by weight of precipitated barium sulfate, and 10 parts by weight of titanium dioxide. To a sand mill, grind to a fineness of less than 50 microns;

[0041] Similarly, add 15 parts by weight of water-based epoxy resin emulsion, 20 parts by weight of conductive powder and stir evenly, add 0.2 parts by weight of water-based wetting agent, stir evenly, and gradually add 0.3 parts by weight of defoamer and 0.3 parts by weight of leveling agent and 0.5...

Embodiment 3

[0054] The product obtained in embodiment 1 is carried out construction coating according to the following operation steps:

[0055] (1) The pre-treatment of the inner wall of the steel storage tank; the spray rust removal reaches the Sa2.5-3.0 level specified in GB8923-2011, and the surface roughness Rz50-80 microns.

[0056] (2) Spray, roll or brush on the inner wall of the pretreated steel storage tank;

[0057] (3) Prepare the water-based anti-corrosion fluorocarbon coating according to the weight ratio of components A and B of 8-12:1, add a small amount of water to adjust the viscosity to 25-35 seconds / paint 4#, 23°C, spray and roll on the clean surface Paint or brush anti-corrosion water-based epoxy static conductive paint.

[0058] (4) Dry the inner wall of the steel storage tank after coating with anti-corrosion paint at room temperature for more than 24 hours, measure the thickness of the coating film, and paint to reach the specified thickness according to the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com