Carbon-coated aluminum oxide carrier with bimodal pore structure, and preparation method thereof

A carbon-alumina, bimodal pore technology, applied in the field of carbon-coated alumina carrier and its preparation, can solve problems such as inapplicability, and achieve the effects of simple equipment, economical cost saving, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 ammonium aluminum carbonate A1

[0027] Weigh 100g of aluminum hydroxide dry rubber powder (Yantai Henghui Chemical Co., Ltd.), 310g of ammonium bicarbonate (product of Beijing Chemical Factory) and 15mL of polyethylene glycol (PEG-400, Tianjin Guangfu Chemical Reagent Factory) and add them to 600mL of deionized water Stir, then transfer the mixed material into a 1L airtight pressure vessel lined with polytetrafluoroethylene, sink at 100°C for 8 hours, filter and dry the resulting white filter cake at 100°C for 4 hours to obtain ammonium aluminum carbonate A1.

Embodiment 2

[0028] The preparation of embodiment 2 ammonium aluminum carbonate A2

[0029] Weigh 400g of aluminum nitrate (product of Beijing Chemical Plant), 300g of ammonium bicarbonate and 15mL of polyethylene glycol, mix and grind for 20 minutes, then transfer the mixed material into a 1L airtight pressure vessel with a polytetrafluoroethylene liner, at 100°C Precipitate for 8 hours, filter and dry the resulting white filter cake at 100°C for 4 hours to obtain aluminum ammonium carbonate A2.

Embodiment 3

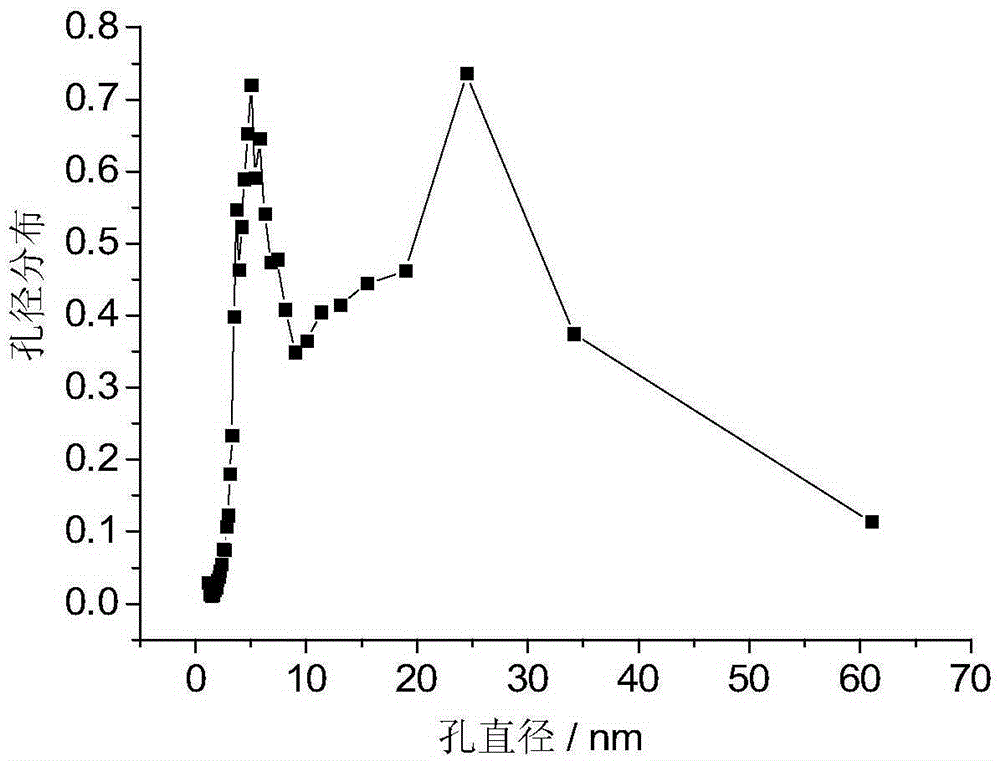

[0032] The weight ratio of hydrated alumina to aluminum ammonium carbonate is 1:9, and the ratio of the weight sum of hydrated alumina and aluminum ammonium carbonate to the carbon precursor is 7:3. Take by weighing 10g pseudo-boehmite dry rubber powder (Shanghai Xinnian Petrochemical Auxiliary Factory), mix 90 grams of ammonium aluminum carbonate A1, use 30g glucose (Tianjin Guangfu Chemical Reagent Factory) as carbon precursor and 2.5g concentrated nitric acid (mass Fraction is 69.2%, Beijing chemical factory product) and 80g deionized water are made into solution, then mixed and stirred to form a plastic body, extruded into Ф1.2mm strips on the extruder, dried at 100°C for 4 hours, and then dried under N 2 Under the atmosphere, the temperature was raised from room temperature to 550° C. for 1 hour and kept for 4 hours to obtain a carbon-coated alumina carrier a, whose physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com