Fin-type field-effect tube formation method

A fin field effect tube and fin technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the electrical performance of the fin field effect tube needs to be improved, so as to avoid the shadow effect, improve the electrical performance, and block the effect weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It can be seen from the background art that the electrical performance of the fin field effect transistor formed in the prior art needs to be improved.

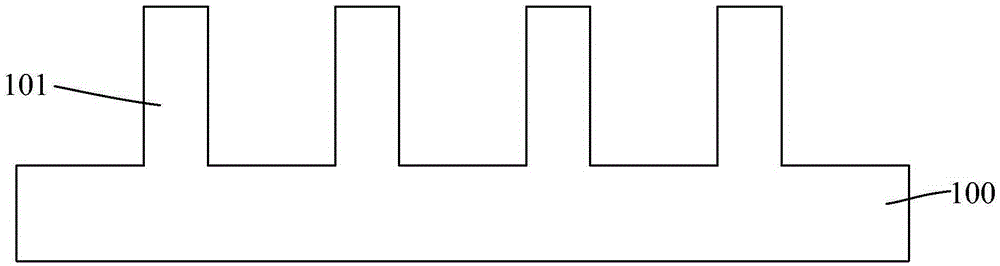

[0033] According to the research on the formation method of FinFET, refer to figure 1 , provide the substrate 100, after forming several discrete fins 101 on the substrate 100, it is usually necessary to perform ion implantation on the fins 101, and doping the fins 101 to improve the electrical performance of the fin field effect transistor, such as the threshold voltage ( Vt), saturation current (Idsat), etc.

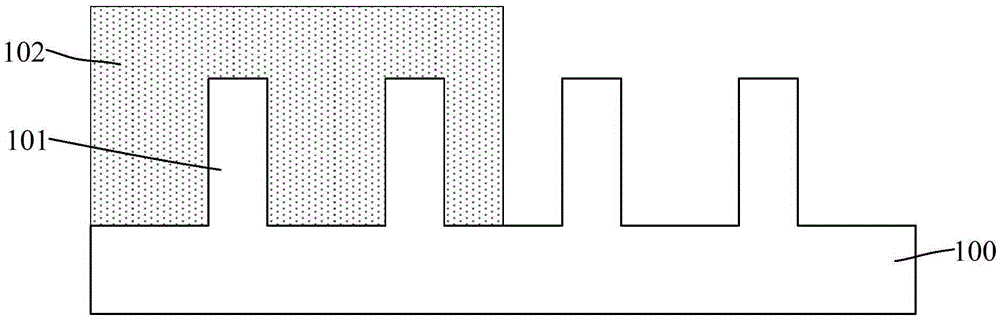

[0034] The process steps of doping the fin portion 101 include: figure 2 , forming an initial photoresist layer covering the substrate 100 and the surface of the fin portion 101; exposing the initial photoresist layer; using a developer to clean the exposed initial photoresist layer to form a patterned photoresist layer The resist layer 102 exposes part of the surface of the fin portion 101 and the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com