Thickening agent for cleaning foamed fracturing fluid and preparation method of thickening agent

A technology for cleaning foams and thickeners, applied in chemical instruments and methods, and drilling compositions, etc., can solve the problems of non-negligible compatibility of saturated aqueous solutions, poor temperature resistance of thickeners, and high cost, and achieve high pressure Crack construction effect, strong temperature and shear resistance, and strong foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

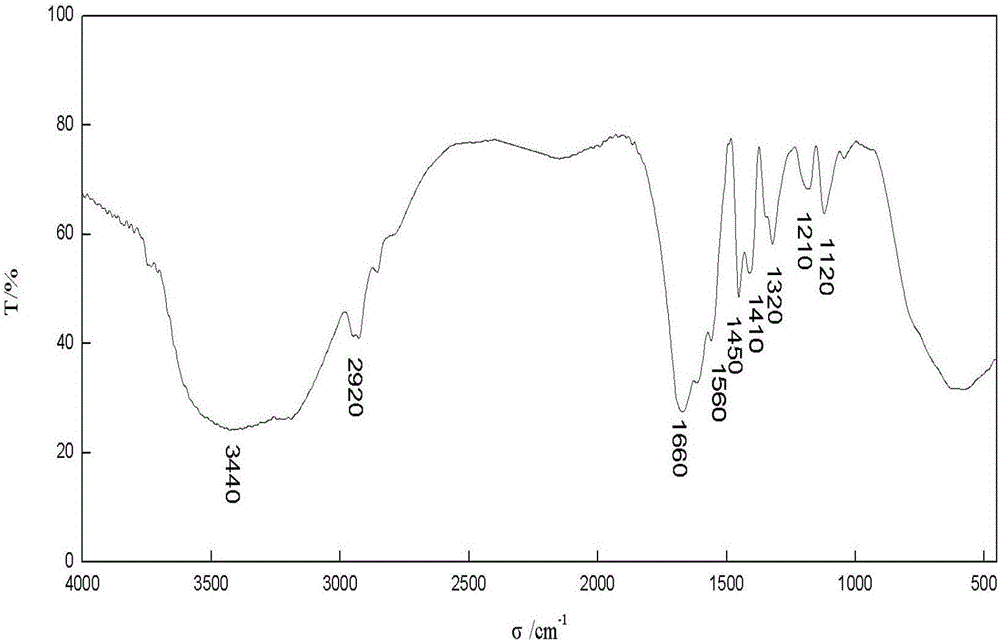

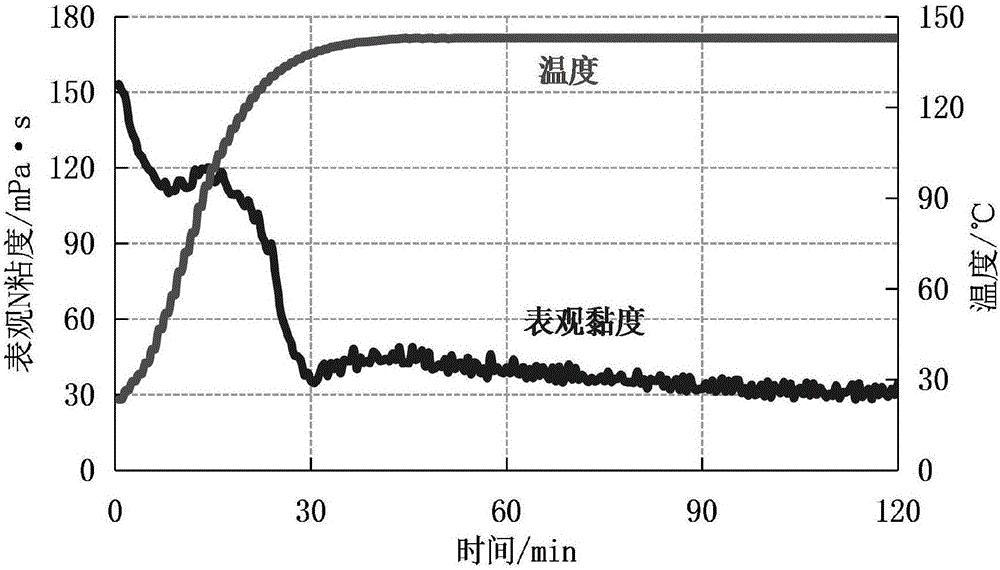

Method used

Image

Examples

Embodiment 1

[0057] The preparation scheme 1 of a thickener for clean foam fracturing fluid provided by the present invention is as follows:

[0058] (1) Reactant pretreatment

[0059] In the feeding tank, benzoyl peroxide is added to deionized water, the ratio is 2% of the total deionized water consumption, dissolved completely and stirred evenly to obtain an aqueous initiator solution (prepared and used now).

[0060] Add deionized water into the high temperature and high pressure reactor, and acrylamide, N, N'-methylenebisacrylamide, N-vinylpyrrolidone, octadecyldimethylallyl ammonium chloride, NH4Cl, ethyl Add the amide into the reaction kettle to make it dissolve in deionized water, and pass nitrogen gas from the bottom of the kettle to control the size of the air flow to make the liquid surface of the solution roll. Join Na 2 CO 3 Adjust the pH value of the system, the pH value of the test is 8.5, adjust the nitrogen flow rate until a small amount of bubbles appear on the liquid s...

Embodiment 2

[0070] The preparation scheme 2 of a thickening agent for clean foam fracturing fluid provided by the present invention is as follows:

[0071] (1) Reactant pretreatment

[0072] In the feed tank, the redox system of benzoyl peroxide / N, N-diethylaniline (mass ratio is 2:3) is added to deionized water, its ratio is 2% of the total deionized water consumption, dissolved Completely and evenly stirred to obtain an aqueous initiator solution (prepared and used now).

[0073] Add deionized water to the high-temperature and high-pressure reactor, and acrylamide, N,N'-methylenebisacrylamide, N-vinylpyrrolidone, dimethyl diallyl ammonium chloride, NaCl, sodium salicylate Add to the reaction kettle to dissolve it in deionized water, and pass nitrogen gas from the bottom of the kettle to control the size of the air flow to make the liquid surface of the solution roll over. When the solids in the solution are completely dissolved and mixed evenly, add NaHCO 3 Adjust the pH value of the...

Embodiment 3

[0083] The preparation optimization scheme of a thickener for clean foam fracturing fluid provided by the present invention is as follows:

[0084] (1) Reactant pretreatment

[0085] In the feeding tank, add sodium perborate / sodium bisulfite (mass ratio 2:3) redox system into deionized water, the ratio is 2% of the total amount of deionized water, dissolve completely and stir evenly to prepare Initiator aqueous solution (made and used now).

[0086] Add deionized water into the high temperature and high pressure reactor, and acrylamide, N,N'-methylenebisacrylamide, N-vinylpyrrolidone, hexadecyldimethylallyl ammonium chloride, KCl, urea Add to the reaction kettle to dissolve it in deionized water, and pass nitrogen gas from the bottom of the kettle to control the size of the air flow to make the liquid surface of the solution roll over. When the solids in the solution are completely dissolved and mixed evenly, add Na 2 CO 3 Adjust the pH value of the system. The test shows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com