High temperature Fe-based solder for brazing 50Mo-50Re alloy and preparation method thereof, and brazing process

A 50mo-50re, brazing technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of low joint performance, hard particle aggregation, uneven element diffusion, etc., to facilitate foil welding, Good surface wetting and spreading, the effect of promoting element diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

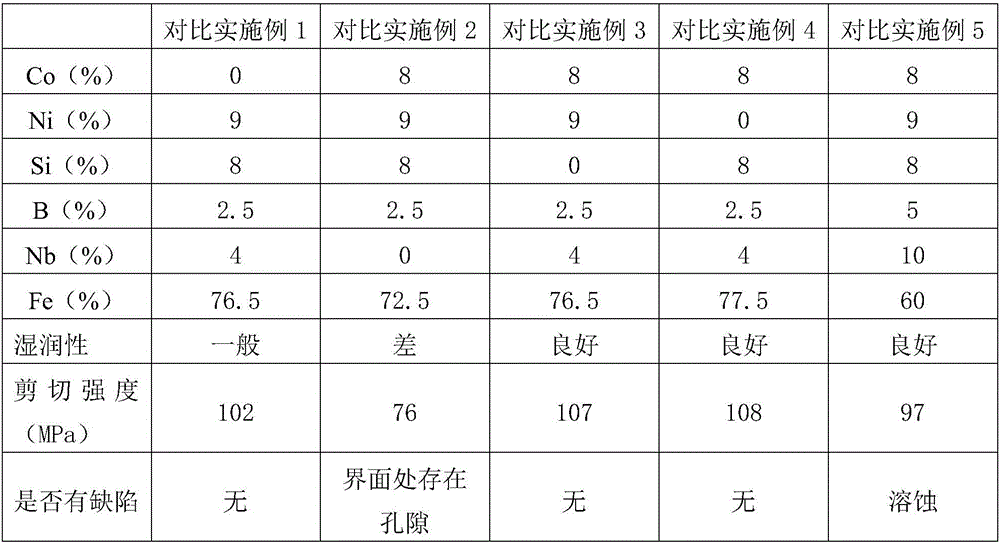

Examples

Embodiment 1

[0033] Molybdenum-rhenium alloy (50% Mo, 50% Re) lap joint vacuum brazing: the size of the molybdenum-rhenium alloy sample is 50mm×2.55mm×0.06mm, and the surface to be brazed is 5mm×2mm.

[0034] The composition and mass percentage ratio of the solder are: Co8%; Ni9%; Si8%; B2.5%; Nb4%, and the balance is Fe.

[0035] The above-mentioned preparation method of a brazing filler metal for molybdenum-rhenium alloy comprises the following steps:

[0036]1) Weigh high-purity 68.5g Fe granules, 8gSi granules, 2.5gB granules, 8gCo granules, 9gNi granules and 4gNb granules by mass percentage to prepare a mixture, put them into a container with acetone, and carry out at a temperature of about 20°C Ultrasonic cleaning for 20 minutes;

[0037] 2) drying the mixture after ultrasonic cleaning in step 1 at a temperature of 30-50° C. to obtain a dried mixture;

[0038] 3) The mixture Fe, Si and B are prepared by vacuum induction smelting to prepare a solder master alloy with uniform composi...

Embodiment 2

[0049] Molybdenum-rhenium alloy (50% Mo, 50% Re) lap joint vacuum brazing: the size of the molybdenum-rhenium alloy sample is 50mm×5mm×0.06mm, and the surface to be brazed is 5mm×1mm lapping surface.

[0050] The composition and mass percentage ratio of the solder are: Co9%; Ni9%; Si5.5%; B2.5%; Nb3% and the balance is Fe. According to the preparation method in Example 1, the thickness of the brazing filler metal prepared was 40 μm.

[0051] The brazing process steps are:

[0052] (1) Preparation stage: clean the overlapping surface of the molybdenum-rhenium alloy sample to be brazed, remove the surface impurities, oil stains and oxide film, use W7 metallographic sandpaper to grind smooth, and put the molybdenum-rhenium alloy and brazing foil Put them together in acetone, use ultrasonic cleaning for 15-20 minutes, and dry them;

[0053] (2) Assembly stage: place the cleaned solder foil between the overlapping surfaces of the molybdenum-rhenium alloy, and fit it tightly in th...

Embodiment 3

[0057] Molybdenum-rhenium alloy (50% Mo, 50% Re) lap joint vacuum brazing: the size of the molybdenum-rhenium alloy sample is 30mm×5mm×0.2mm, and the surface to be brazed is 5mm×2mm lapping surface.

[0058] The composition and mass percentage ratio of the solder are: Co8%; Ni9%; Si5.5%; B2.5%; Nb4.5%, and the balance is Fe. The thickness of the solder is 30 μm.

[0059] The brazing process steps are:

[0060] (1) Preparation stage: clean the overlapping surface of the molybdenum-rhenium alloy sample to be brazed, remove the surface impurities, oil stains and oxide film, use W7 metallographic sandpaper to grind smooth, and put the molybdenum-rhenium alloy and brazing foil Put them together in acetone, use ultrasonic cleaning for 15-20 minutes, and dry them;

[0061] (2) Assembly stage: place the cleaned solder foil between the molybdenum-rhenium alloy overlapping surfaces, and fit it tightly in a special brazing fixture to ensure the accuracy of the connection, and place a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com