Method for recycling Au from electronic components of waste mobile phone

A technology for electronic components and electronic components, applied in the direction of improving process efficiency, can solve problems such as economic benefits not as good as cyanidation, unsuitable for processing alkaline gangue, immature process, etc., and achieve significant environmental benefits and social benefits. Benefit, mature extraction and reduction technology, good metal enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

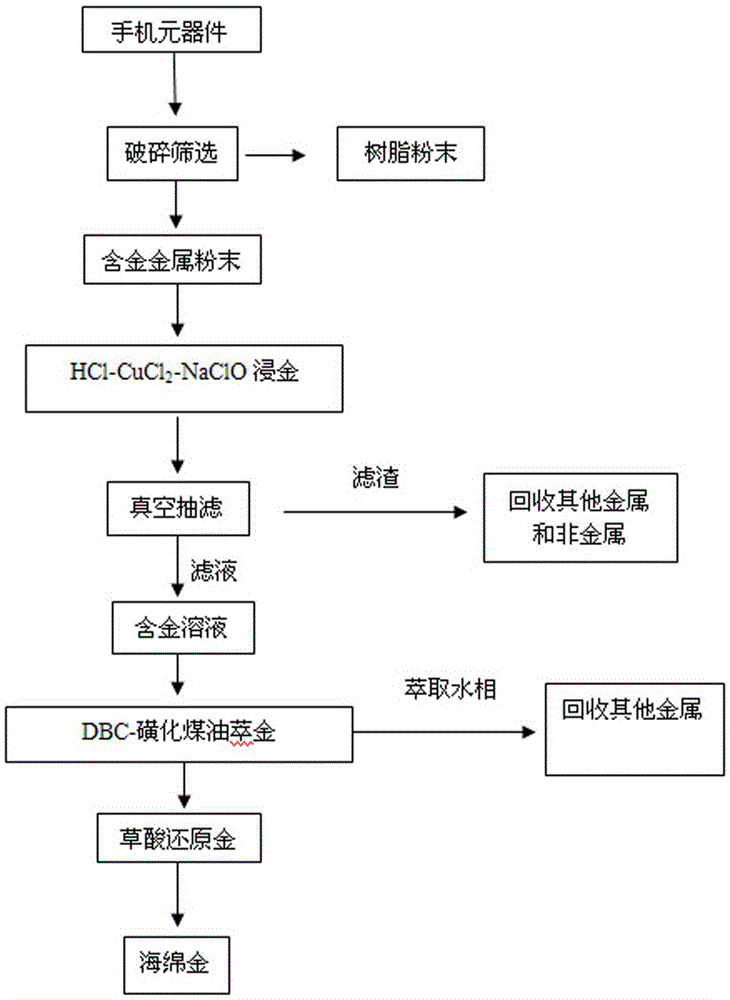

[0049] A method for recovering gold (Au) from waste mobile phone electronic components, the method for recovering gold (Au) is divided into pretreatment, HCl-CuCl 2 -NaClO system immersion Au, DBC-sulfonated kerosene system extraction of Au and oxalic acid reduction of Au four parts, including the following steps:

[0050] 1. Randomly select 500 waste mobile phones, remove the circuit board after manual disassembly, use a heat gun to blow off the mobile phone components on the circuit board, and use a jaw crusher and a ball mill to crush the waste mobile phone electronic components into powder;

[0051] 2. Separate the metal material and non-metal material in the electronic component powder obtained in step 1 by winnowing to obtain about 500 g metal powder and about 1500 g epoxy resin powder respectively, and then grind the metal material to 100 mesh above;

[0052] 3. Weigh 4g of the metal-containing Au powder obtained in step (2) and add it to 180mL 2 mol.L -1 HCl in a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com