Novel degradable environment-friendly photoelectric material for solar battery

A technology of solar cells and photoelectric materials, which is applied in the field of solar cell material preparation and new degradable and environmentally friendly photoelectric materials for solar cells, and can solve the problems of high recycling and processing costs of waste solar cells, heavy metal elements polluting the environment, and difficult degradation of photoelectric materials. , to achieve the effect of being conducive to popularization and application, high photoelectric conversion efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

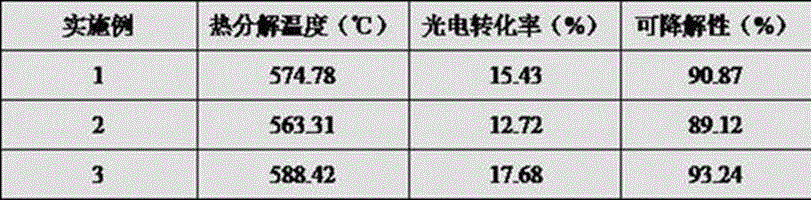

Examples

preparation example Construction

[0045] The preparation method of the degradable environment-friendly photoelectric material for the novel solar cell comprises the following steps:

[0046] S1: Mix hydroxyl polyester resin, hydroxypropionic acid valeric acid copolyester, and acryl carbazole, then add polylactic acid and dehydroacetic acid, stir at a speed of 80-150r / min and raise the temperature to 78°C, keep the temperature constant Continue to stir at 80-150r / min for 3-5min to obtain a suspension;

[0047] S2: Add alkaline clay, sodium stearate, sodium silicate, corn stalk fiber, and synthetic agents to the suspension prepared in step S1, control the temperature at 135-150°C, and stir at a speed of 100-200r / min 1-3h, prepared mixed solution I;

[0048] The preparation method of described synthetic agent, comprises the following steps:

[0049] S21: Mix the generating agent, coupling agent, and compatibilizer and heat up to 120-135°C, and react at a rotation speed of 200-300r / min for 40-60 min to obtain ma...

Embodiment 1

[0060] A new type of degradable and environmentally friendly photoelectric material for solar cells is made of the following raw materials in units of weight: 45 parts of hydroxyl polyester resin, 25 parts of hydroxypropionate valeric acid copolyester, 16 parts of acryl carbazole, alkali 15 parts of clay, 12 parts of sodium stearate, 10 parts of sodium silicate, 8 parts of corn straw fiber, 10 parts of polylactic acid, 7 parts of dehydroacetic acid, 6 parts of degradation agent, 8 parts of synthetic agent, 5 parts of starch binder 2.5 parts of antibacterial agent, 1.5 parts of stabilizer I, 1.5 parts of ultraviolet absorber;

[0061] The degradation agent is made of the following raw materials by weight: 2.2 parts of ammonium phosphate, 1.4 parts of aminotriethylenephosphonic acid, 1.2 parts of ethylenediaminetetracarboxylic acid, 0.9 parts of dodecyldimethylbenzyl ammonium bromide part, 0.3 part of titanium dioxide;

[0062] The synthetic agent is made of the following raw m...

Embodiment 2

[0083] A new type of degradable and environmentally friendly optoelectronic material for solar cells, made of the following raw materials in units of weight: 34 parts of hydroxyl polyester resin, 20 parts of hydroxypropionate valeric acid copolyester, 12 parts of acrylcarbazole, alkali 10 parts of clay, 8 parts of sodium stearate, 8 parts of sodium silicate, 6 parts of corn straw fiber, 7 parts of polylactic acid, 6 parts of dehydroacetic acid, 5 parts of degradation agent, 6 parts of synthetic agent, 4 parts of starch binder 1 part, 2 parts of antibacterial agent, 1 part of stabilizer I, 1 part of ultraviolet absorber;

[0084] The degradation agent is made of the following raw materials in units of weight: 2 parts of ammonium phosphate, 1.2 parts of aminotriethylenephosphonic acid, 1 part of ethylenediaminetetracarboxylic acid, 0.6 parts of dodecyl dimethyl benzyl ammonium bromide part, 0.2 part of titanium dioxide;

[0085] The synthetic agent is made of the following raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com