Method for preparing black silicon by wet process

A black silicon, wet process technology, applied in the field of solar cells, to solve the bottleneck of mass industrialization, improve absorption efficiency, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Wet black silicon preparation, the steps are as follows:

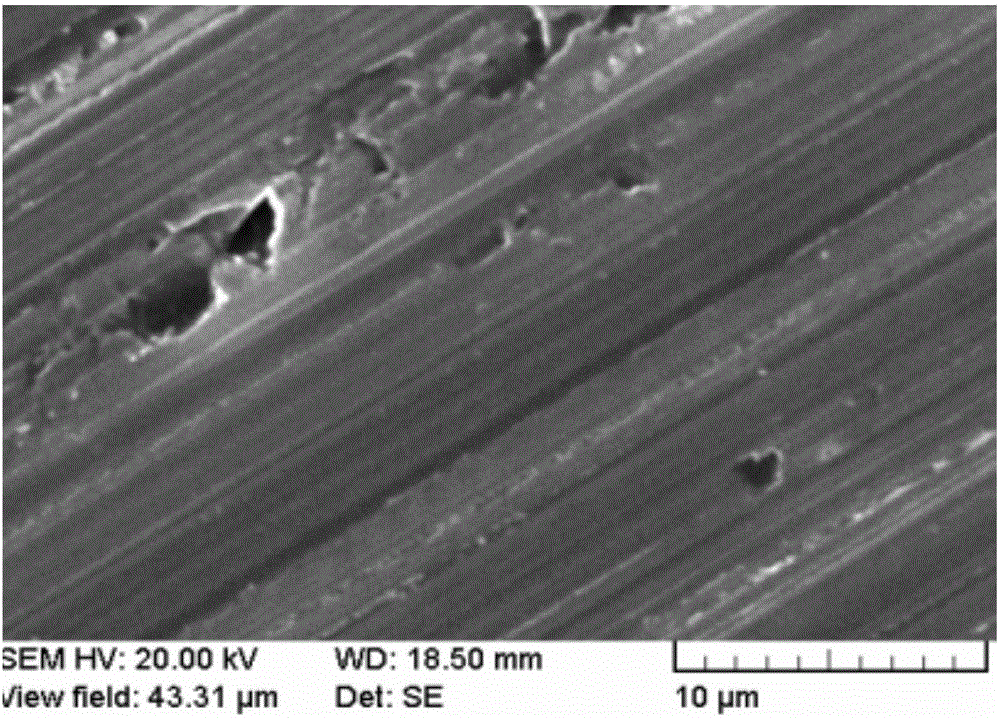

[0038] (1) Select a P-type polysilicon wafer (boron-doped, 1-3Qcm, 156X156mm square, thickness 180μm), because the polysilicon wafer is cut with a diamond wire saw, so the damage during slicing remains on the surface. Add 2% mass additives of NaOH aqueous solution to 3% NaOH aqueous solution, immerse the silicon chip in the above aqueous solution, and corrode in the solution at 65°C for 300 seconds to make the silicon surface structure of the damaged layer uniform and reduce anisotropic scars.

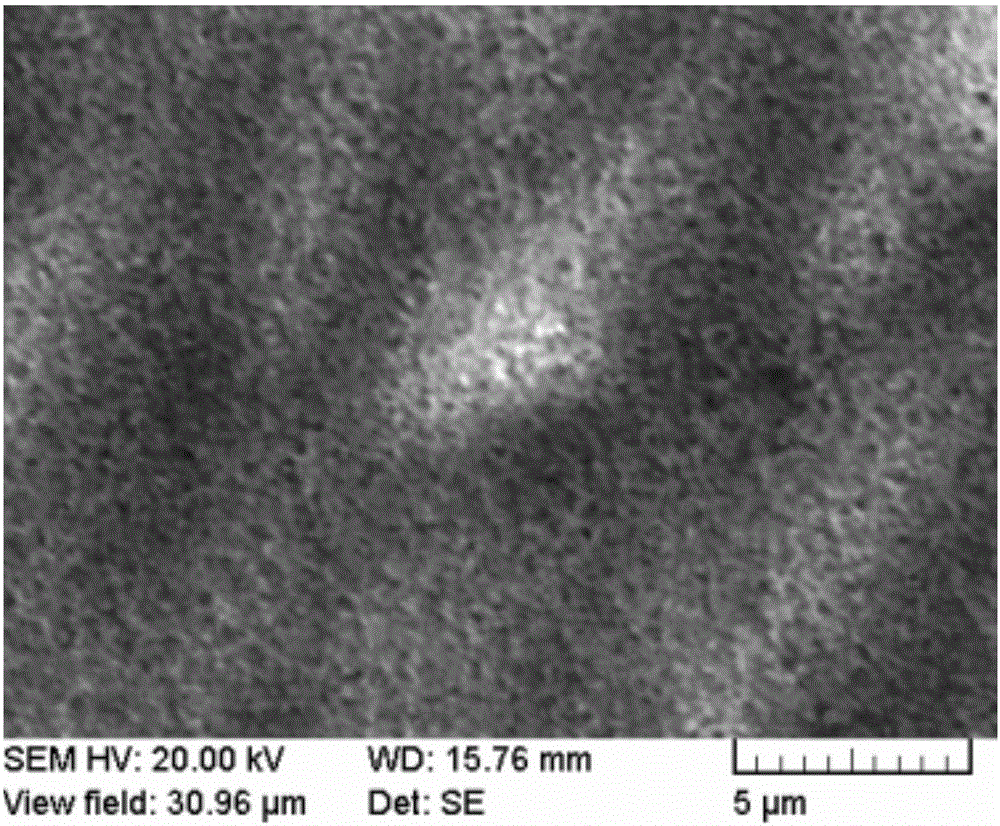

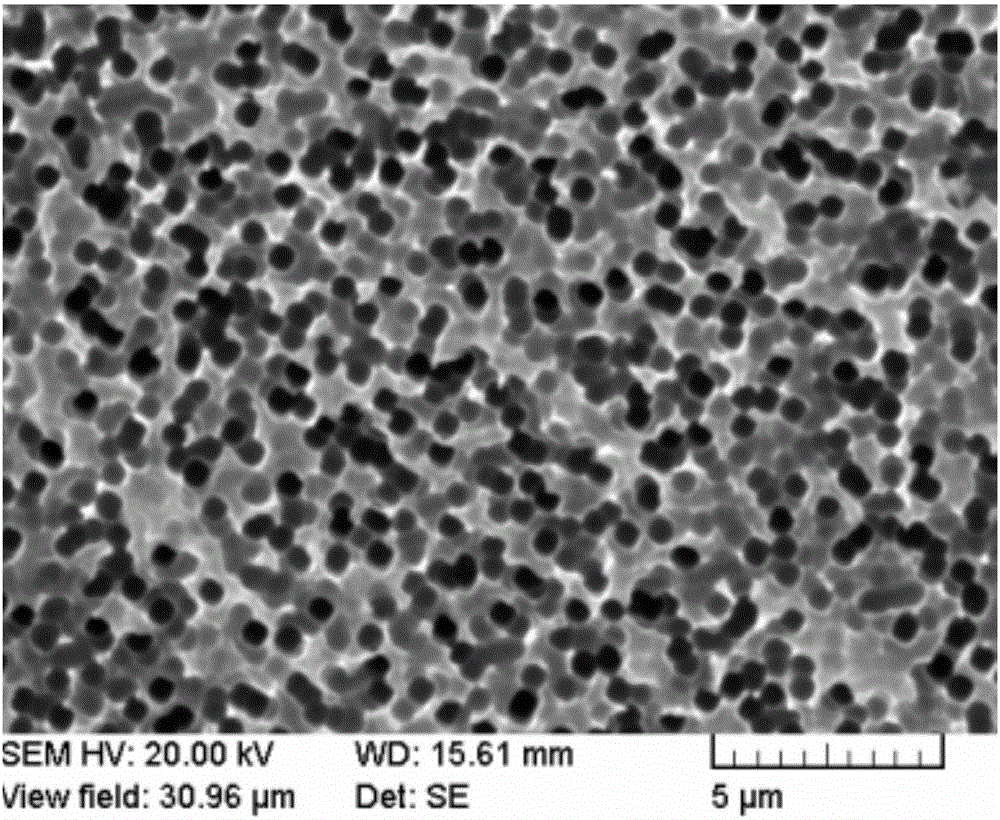

[0039] (2) Rinse the product wafer of step (1) with deionized water; after drying, put it into the metal ion aqueous solution and attach it for 300 seconds at room temperature; wherein, the metal ion is derived from HAuCl 4 and AgNO 3 The combination of HAuCl4 and AgNO3 are electronic grade products. The weight ratio of HAuCl4 to AgNO3 is 1:6, and the total content of HAuCl4 and AgNO3 in the solution is 0.01mol / L. In ...

Embodiment 2

[0047] Wet black silicon preparation, the steps are as follows:

[0048] (1) Select a P-type polysilicon wafer (boron-doped, 1-3Qcm, 156X156mm square, thickness 180μm), because the polysilicon wafer is cut with a diamond wire saw, so the damage during slicing remains on the surface. Add 2% mass additives of NaOH aqueous solution to 3% NaOH aqueous solution, immerse the silicon chip in the above aqueous solution, and corrode in the solution at 65°C for 300 seconds to make the silicon surface structure of the damaged layer uniform and reduce anisotropic scars.

[0049] (2) Rinse the product wafer of step (1) with deionized water; after drying, put it into the metal ion aqueous solution and attach it for 240 seconds at room temperature; wherein, the metal ion is derived from HAuCl 4 and AgNO 3 The combination of HAuCl4 and AgNO3 are electronic grade products. The weight ratio of HAuCl4 to AgNO3 is 5:1.2, and the total content of HAuCl4 and AgNO3 in the solution is 0.005mol / L. ...

Embodiment 3

[0057] Wet process black silicon preparation method, comprises the following steps:

[0058] (1) Immerse the silicon wafer in a 3% sodium hydroxide or potassium hydroxide solution containing additives, the additive amount is 3% of the mass of the alkali solution, and polish the silicon wafer at 50°C for 180 seconds to remove the surface damage of the silicon wafer layer; add additives to avoid sticking bubbles during the corrosion process and cause unclean surfaces;

[0059] (2) Immerse the polished silicon chip in a metal ion solution with a concentration of 0.025mol / L for 100 seconds at normal temperature, so that the metal ion is attached to the silicon chip; the metal ion is a combination of platinum ion and palladium ion; during the attachment process, also Add concentrated hydrofluoric acid and a high molecular weight polymer with a molecular weight of 10000, the concentration of the high molecular polymer is 25ppm, and the mass percentage concentration of the concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com