Preparation method of nano-silicon-dioxide-modified water-based polyurethane

A technology of nano-silica and water-based polyurethane, which is applied in the modification of water-based polyurethane and the preparation of nano-silica sol modified by silane coupling agent, which can solve the problems of difficulty and less water-based polyurethane modification, and achieve good adhesion Hardness, easy industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

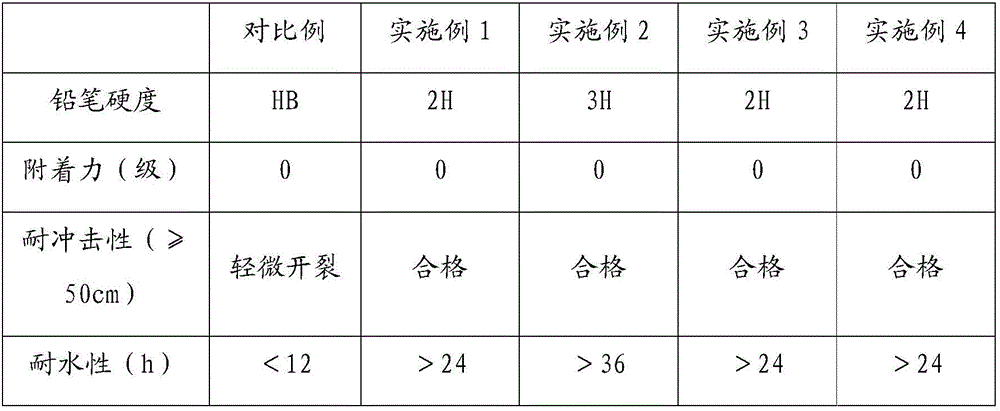

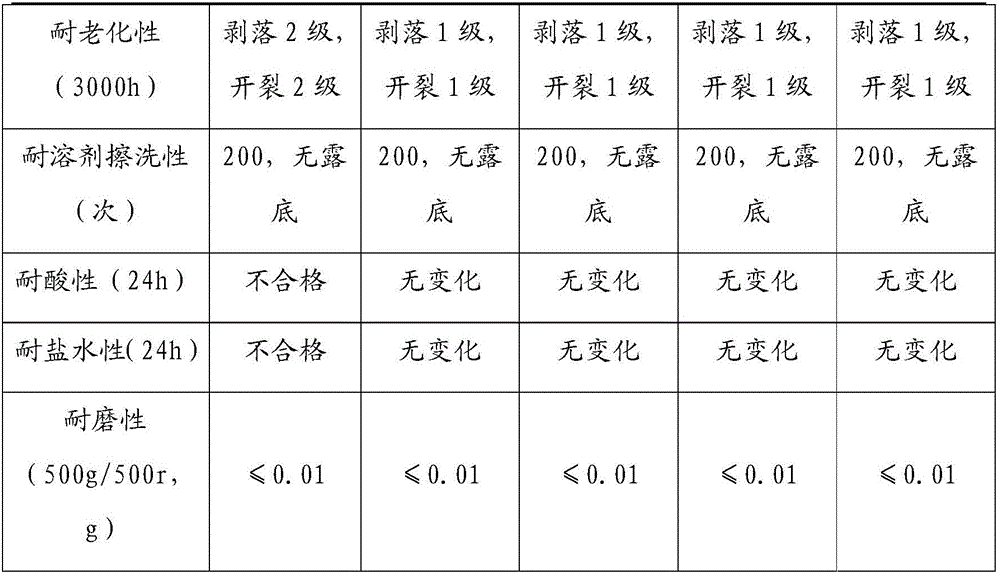

Examples

preparation example Construction

[0037] A kind of preparation method of nano silicon dioxide modified waterborne polyurethane of the present invention, comprises the steps:

[0038] (1) Add macromolecular polyols into the reaction flask, distill under reduced pressure at 100°C for 30-60 minutes until the water content is lower than 0.5%, cool down to 60°C, add polyisocyanate and catalyst, and heat up to 70-90°C for reaction 2 -4 hours;

[0039](2) Cool down to 60°C, add a small molecule alcohol chain extender and a small molecule hydrophilic chain extender, raise the temperature to 70-90°C and react for 2-4 hours until the NCO content reaches the theoretical value;

[0040] (3) Lower the temperature to 40-60° C., reduce the viscosity with a solvent, add a salt-forming agent, and react for 15-30 minutes to obtain a prepolymer of water-based polyurethane.

[0041] (4) Nano-silica sol modified by silane coupling agent: Dilute the nano-silica sol with a small amount of isopropanol, then mix it with silane coupli...

Embodiment 1

[0055] A preparation method for nano silicon dioxide modified water-based polyurethane, comprising the steps of:

[0056] (1) Add 40 g of polyethylene adipate with a molecular weight of 1000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 60°C, add 20g of toluene diisocyanate, 0.2g of dibutyltin dilaurate, and heat up React at 70°C for 4 hours;

[0057] (2) Cool down to 60°C, add 2g of 1,4-butanediol and 2g of 2,2-dimethylolpropionic acid, raise the temperature to 70°C and react for 4 hours until the NCO content reaches the theoretical value;

[0058] (3) cooling to 40° C., and after reducing the viscosity with 10 g of acetone, add 2 g of triethylamine, and react for 30 minutes to obtain a prepolymer of water-based polyurethane;

[0059] (4) 20g of nano-silica sol was diluted with 10g of isopropanol, then mixed with 10g of methyltrimethoxysilane, stirred and reacted at room temperature for 30 minutes, to obtain nano-silica sol mod...

Embodiment 2

[0062] A preparation method for nano silicon dioxide modified water-based polyurethane, comprising the steps of:

[0063] (1) Add 60g of polytetrahydrofuran diol with a molecular weight of 2000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 60°C, add 40g of hexamethylene diisocyanate and 0.5g of stannous octoate, and heat up to 90°C React for 2 hours;

[0064] (2) Cool down to 60°C, add 5g of diethylene glycol and 8g of 2,2-dimethylolbutyric acid, raise the temperature to 90°C and react for 2 hours until the NCO content reaches the theoretical value;

[0065] (3) cooling to 60° C., and after reducing the viscosity with 20 g of butanone, add 5 g of ammonia water and react for 15 minutes to obtain a prepolymer of water-based polyurethane;

[0066] (4) Dilute 80g of nano-silica sol with 20g of isopropanol, then mix it with 40gKH560, stir and react at room temperature for 30 minutes, to obtain nano-silica sol modified by silane coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com