A centrifugal casting furnace tube and its preparation process

A preparation process and centrifugal casting technology, applied in the direction of improving process efficiency, etc., can solve problems such as grain boundary embrittlement, shortened service life of furnace tubes, and reduced creep resistance of furnace tube materials, so as to achieve fine grains and impurities The effect of reducing the content and improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

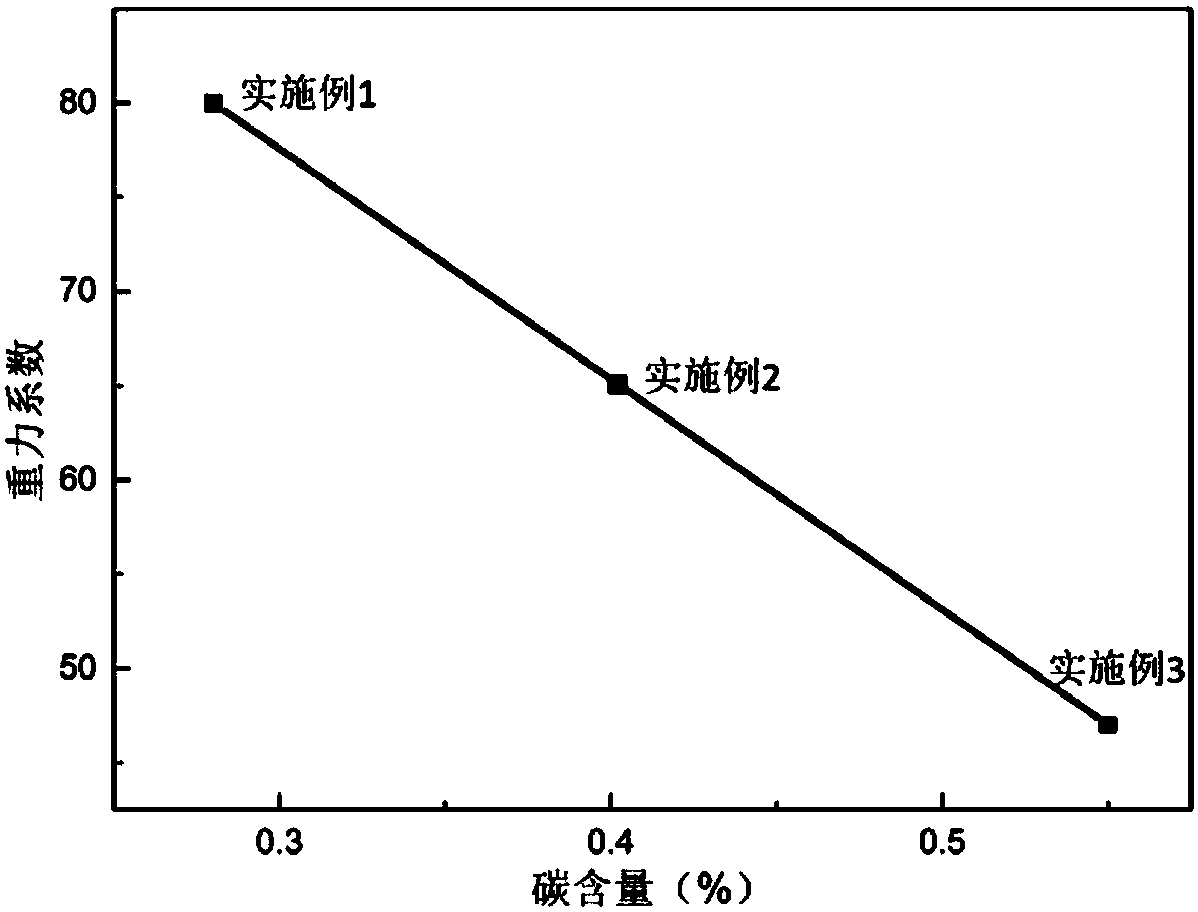

Embodiment 1

[0033] Centrifugal casting of pipes with a size of Φ550 / 350×2000mm, the casting method is

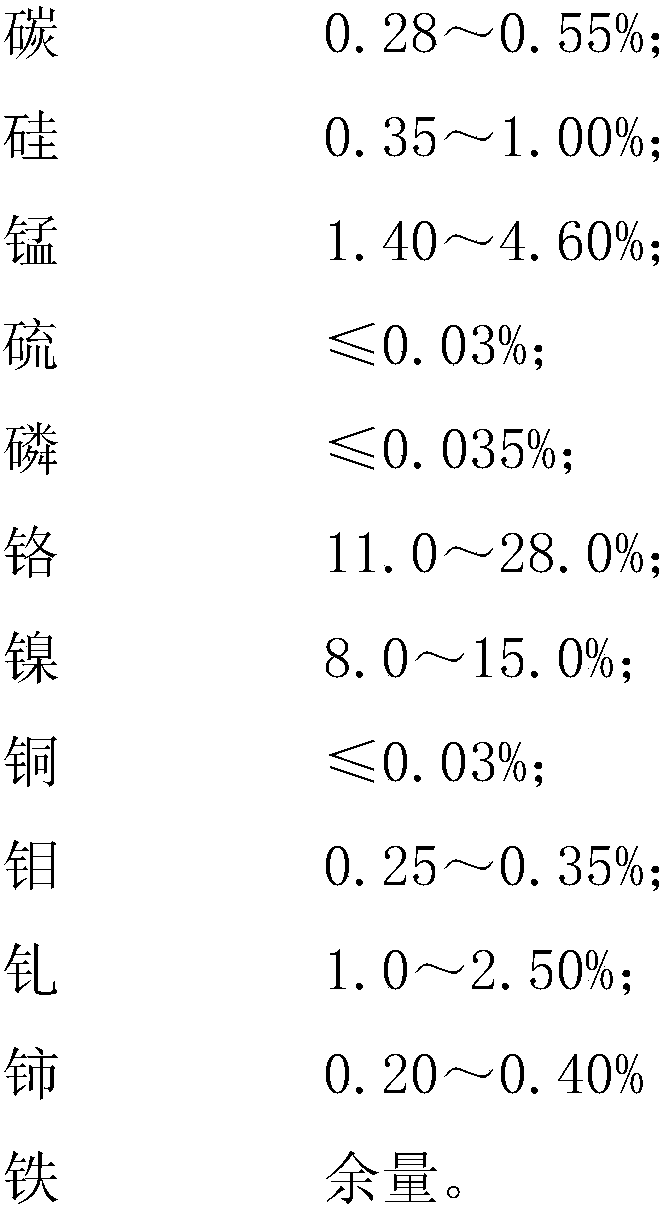

[0034] (1), determine the composition of the furnace tube material and weigh the ingredients according to mass percentage (wt%):

[0035]

[0036]

[0037] (2) Heat scrap steel in an electric furnace to about 1500°C and melt it. After the molten steel is melted, add ferromanganese and ferrosilicon to melt it in turn, and use aluminum wire to deoxidize, then add pure nickel, ferromolybdenum, and ferrochrome in turn. , deoxidize again with aluminum wire and remove slag on the molten steel surface, then add rare earth nickel-gadolinium and nickel-cerium intermediate alloy in turn, deoxidize again with aluminum wire, remove slag on the molten steel surface and let it stand to obtain molten steel;

[0038] (3) According to the formula N=20×(G / r) 1 / 2 , Calculate the centrifugal speed of the pipe cavity of centrifugal casting. Among them, N is the centrifugal speed of the cavity, r is ...

Embodiment 2

[0041] Embodiment 2: The centrifugal casting size is the pipe material of Φ460 / 350×2000mm, and its casting method is

[0042] (1) Determine the composition of the furnace tube material and weigh the ingredients by mass percentage (wt%):

[0043]

[0044] (2) Heat scrap steel in an electric furnace to about 1500°C and melt it. After the molten steel is melted, add ferromanganese and ferrosilicon to melt it in turn, and use aluminum wire to deoxidize, then add pure nickel, ferromolybdenum, and ferrochrome in turn. , deoxidize again with aluminum wire and remove slag on the molten steel surface, then add rare earth nickel-gadolinium and nickel-cerium intermediate alloy in turn, deoxidize again with aluminum wire, remove slag on the molten steel surface and let it stand to obtain molten steel;

[0045] (3) According to the formula N=20×(G / r) 1 / 2, Calculate the centrifugal speed of the pipe cavity of centrifugal casting. Among them, N is the centrifugal speed of the cavity, r ...

Embodiment 3

[0048] Embodiment 3: The centrifugal casting size is the pipe material of Φ420 / 240 * 2000mm, and its casting method is

[0049] ((1) Determine the composition of the furnace tube material and weigh the ingredients by mass percentage (wt%):

[0050]

[0051] (2) Heat scrap steel in an electric furnace to about 1500°C and melt it. After the molten steel is melted, add ferromanganese and ferrosilicon to melt it in turn, and use aluminum wire to deoxidize, then add pure nickel, ferromolybdenum, and ferrochrome in turn. , deoxidize again with aluminum wire and remove slag on the molten steel surface, then add rare earth nickel-gadolinium and nickel-cerium intermediate alloy in turn, deoxidize again with aluminum wire, remove slag on the molten steel surface and let it stand to obtain molten steel;

[0052] (3) According to the formula N=20×(G / r) 1 / 2 , Calculate the centrifugal speed of the pipe cavity of centrifugal casting. Among them, N is the centrifugal speed of the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com