Novel lamellar molybdenum disulfide-based nano-immune adjuvant and its preparation method and application

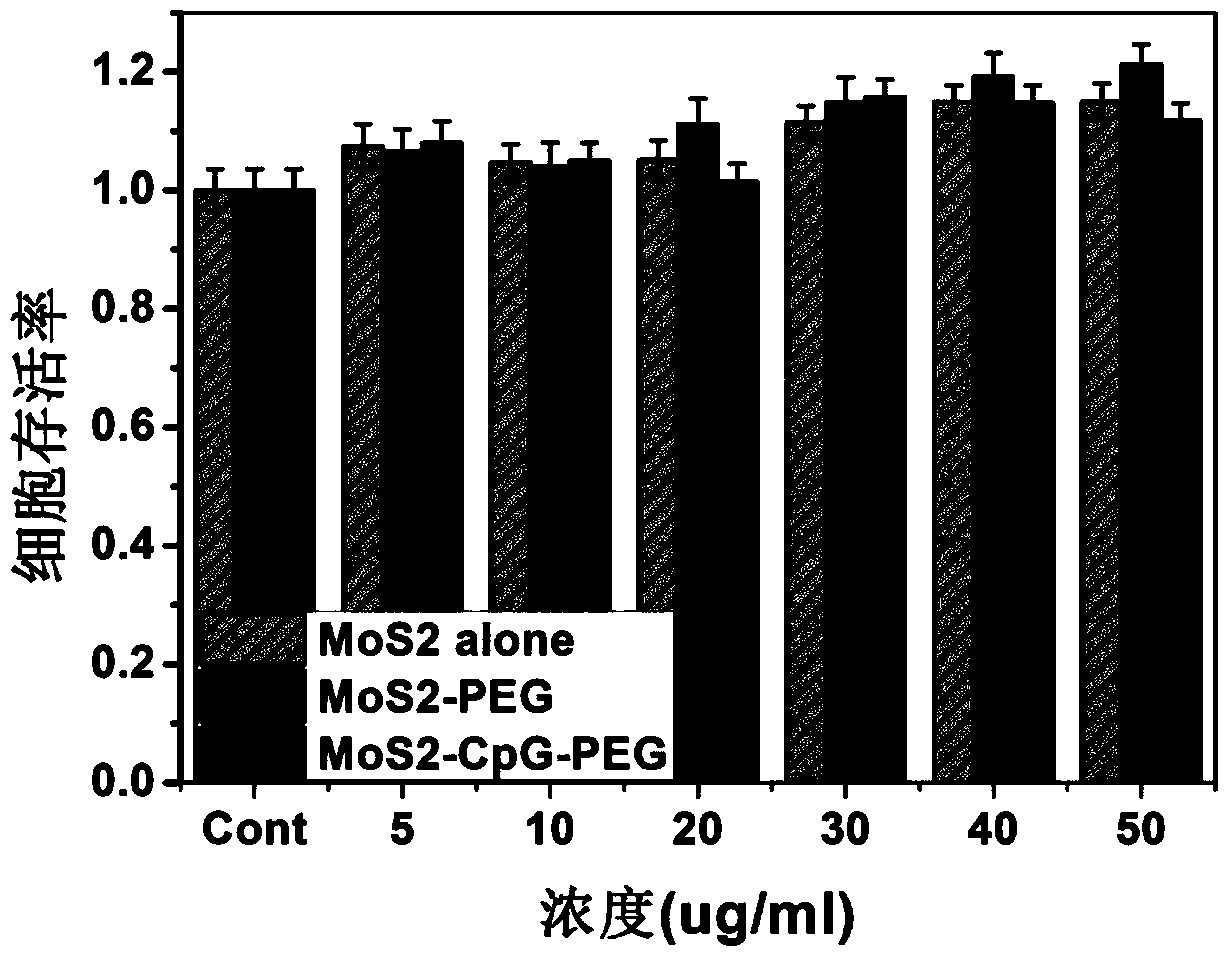

A molybdenum disulfide, immune adjuvant technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, antibody medical ingredients, etc. Toxicity, enhanced immune response, increased secretion levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

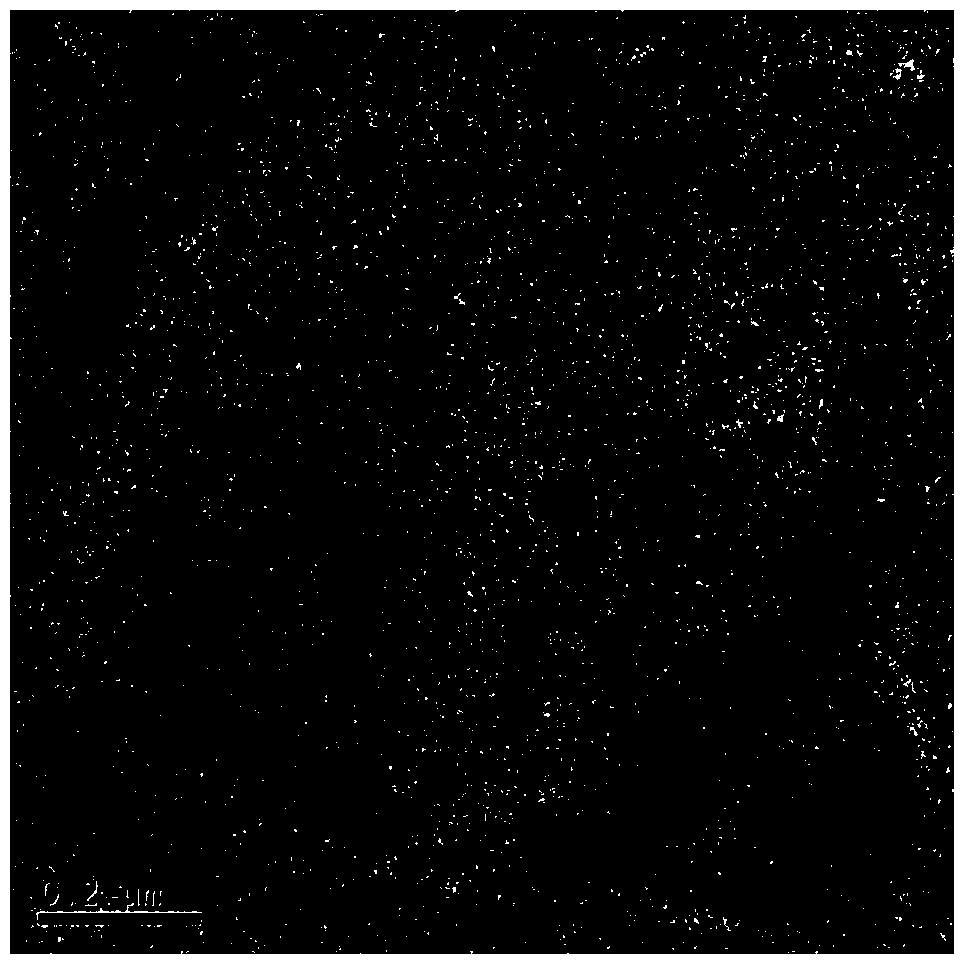

[0064] A. Preparation of molybdenum disulfide nanosheets

[0065] (1) Weigh 500mg of molybdenum disulfide powder (99%) and place it in a 10mL dry round-bottomed flask, feed nitrogen, add 5mL of 1.6mol / L n-butyllithium dispersed in hexane, and react at room temperature for 48h;

[0066] (2) After the reaction is over, add hexane, dilute the reaction solution, and centrifuge for 10 min; disperse the lower layer of sediment with hexane, and centrifuge twice;

[0067] (3) Take the lower layer of precipitate and disperse it in aqueous solution, sonicate until no bubbles are generated; centrifuge for 10 minutes, remove the lower layer, take the supernatant, and dialyze with a dialysis membrane with a molecular cut-off of 14kDa for 48 hours to obtain molybdenum disulfide nanosheets with less than 10 sheets aqueous solution.

[0068] B. Preparation of molybdenum disulfide-based nano-immune adjuvant with small particle size and uniform size

[0069] (1) Ultrasonically operate the mol...

Embodiment 2

[0084] A. Preparation of molybdenum disulfide nanosheets

[0085] (1) Weigh 500mg of molybdenum disulfide powder (99%) and place it in a 10mL dry round-bottomed flask, feed nitrogen, add 5mL of 1.6mol / L n-butyllithium dispersed in hexane, and react at room temperature for 48h;

[0086] (2) After the reaction is over, add hexane, dilute the reaction solution, and centrifuge for 10 min; disperse the lower layer of sediment with hexane, and centrifuge twice;

[0087] (3) Take the lower layer of precipitate and disperse it in aqueous solution, sonicate until no bubbles are generated; centrifuge for 10 minutes, remove the lower layer, take the supernatant, and dialyze with a dialysis membrane with a molecular cut-off of 14kDa for 48 hours to obtain molybdenum disulfide nanosheets with less than 10 sheets aqueous solution.

[0088] B. Preparation of molybdenum disulfide-based nano-immune adjuvant with small particle size and uniform size

[0089] (1) Ultrasonically operate the mol...

Embodiment 3

[0104] A. Preparation of molybdenum disulfide nanosheets

[0105] (1) Weigh 500mg of molybdenum disulfide powder (99%) and place it in a 10mL dry round-bottomed flask, feed nitrogen, add 5mL of 1.6mol / L n-butyllithium dispersed in hexane, and react at room temperature for 48h;

[0106] (2) After the reaction is over, add hexane, dilute the reaction solution, and centrifuge for 10 min; disperse the lower layer of sediment with hexane, and centrifuge twice;

[0107] (3) Take the lower layer of precipitate and disperse it in aqueous solution, sonicate until no bubbles are generated; centrifuge for 10 minutes, remove the lower layer, take the supernatant, and dialyze with a dialysis membrane with a molecular cut-off of 14kDa for 48 hours to obtain molybdenum disulfide nanosheets with less than 10 sheets aqueous solution.

[0108] B. Preparation of molybdenum disulfide-based nano-immune adjuvant with small particle size and uniform size

[0109] (1) Ultrasonically operate the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com