Preparing method for powder metallurgy high-entropy alloy based composite material

A high-entropy alloy and composite material technology, which is applied in the field of powder metallurgy material preparation, can solve the problems of difficult to control the phase composition of composite materials, reduce the strength of composite materials, and difficult to ensure high-purity high-entropy alloys of composite materials, etc. Entropy alloy matrix interface is well bonded, high specific rigidity and wear resistance and corrosion resistance, and the effect of reinforcement and matrix interface bonding is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

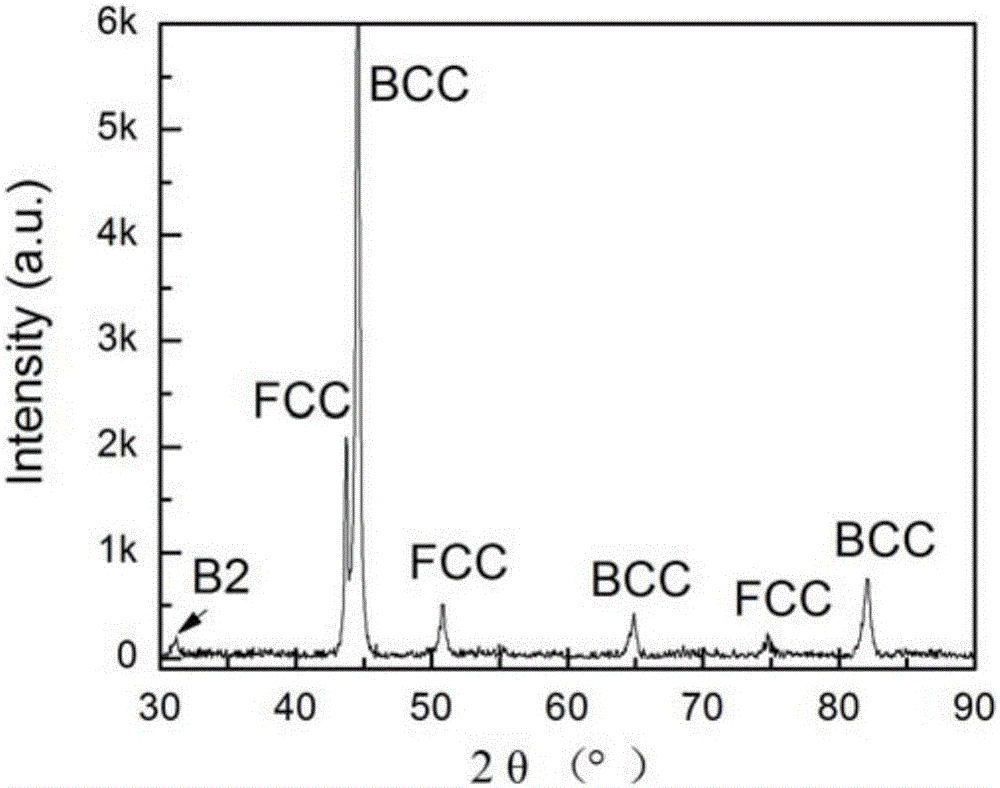

[0049] Prepared with a volume fraction of 5% TiB 2 Enhanced Al 20 Fe 20 Cr 20 co 20 Ni 20 High entropy alloy matrix composites. 1) Preparation of spherical Al 20 Fe 20 Cr 20 co 20 Ni 20 High-entropy alloy powder (mole fraction), the raw materials are high-purity Al, high-purity Fe, high-purity Cr, high-purity Co and high-purity Ni and other bulk metal materials, which are melted into a melt at 1600 ° C in a medium-frequency induction melting furnace. The body is high-purity argon gas with a gas flow rate of 200L / s and a pressure of 6MPa, 10 6 Under the cooling rate of K / s, it is atomized into a spherical high-entropy alloy powder with a diameter of 30-1 micron. 2) According to the volume fraction of 5% TiB 2 and 95% Al 20 Fe 20 Cr 20 co 20 Ni 20 High-entropy alloy weighing TiB with an average diameter of 1 micron 2 powder and an average diameter of 10 µm Al 20 Fe 20 Cr 20 co 20 Ni 20 High-entropy alloy powder, the powder is mixed evenly on a ball mill, a...

Embodiment 2

[0051] Prepared with a volume fraction of 25% TiB 2 Enhanced Al 25 Fe 15 Cr 15 co 15 Ni 20 Ti 5 Cu 5 High entropy alloy matrix composites. 1) Preparation of spherical Al 25 Fe 15 Cr 15 co 15 Ni 20 Ti 5 Cu 5 High-entropy alloy powder (mole fraction), the raw materials are high-purity Al, high-purity Fe, high-purity Cr, high-purity Co, high-purity Ni, high-purity Ti and high-purity Cu and other bulk metal materials, in the medium frequency induction melting furnace 1800 It melts into a melt at ℃, and the melt is in high-purity argon with a gas flow rate of 80L / s and a pressure of 4.5MPa, 10 4 Under the cooling rate of K / s, it is atomized into spherical high-entropy alloy powder with a diameter of 50-5 microns. 2) According to volume fraction 25% TiB 2 and 75% Al 25 Fe 15 Cr 15 co 15 Ni 20 Ti 5 Cu 5 High-entropy alloy weighing TiB with an average diameter of 10 microns 2 powder and Al with an average diameter of 20 μm 25 Fe 15 Cr 15 co 15 Ni 20 Ti 5 ...

Embodiment 3

[0053] Prepared with a volume fraction of 20% TiB 2 Enhanced Al 15 Fe 25 Cr 20 co 15 Ni 15 Ti 10 High entropy alloy matrix composites. 1) Preparation of spherical Al 15 Fe 25 Cr 20 co 15 Ni 15 Ti 10 High-entropy alloy powder (mole fraction), the raw materials are high-purity Al, high-purity Fe, high-purity Cr, high-purity Co, high-purity Ni and high-purity Ti and other bulk metal materials, which are melted at 2000°C in a medium-frequency induction melting furnace Melt, melt in high-purity argon gas with a gas flow rate of 140L / s and a pressure of 6MPa, 10 5 Under the cooling rate of K / s, it is atomized into a spherical high-entropy alloy powder with a diameter of 40-1 micron. 2) According to volume fraction 20% TiB 2 and 80% Al 15 Fe 25 Cr 20 co 15 Ni 15 Ti 10 High-entropy alloy weighing TiB with an average diameter of 5 microns 2 powder and an average diameter of 15 µm Al 15 Fe 25 Cr 20 co 15 Ni 15 Ti 10 High-entropy alloy powder, the powder is mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com