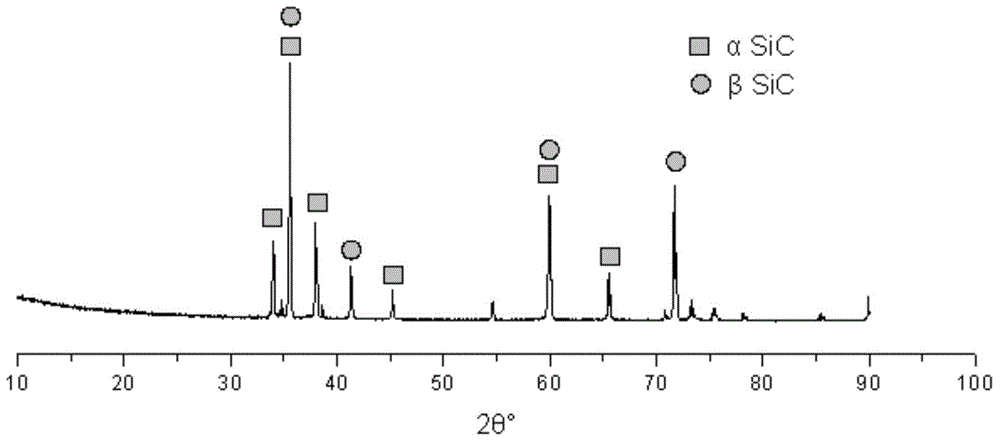

Pure foam silicon carbide support membrane tube with three-gradient pore structure and preparation method

A silicon carbide foam film and silicon carbide foam technology, applied in the field of porous ceramic materials, can solve the problems of limiting the application process of silicon carbide filter materials, the pore structure is not easy to be blown back and cleaned, and the thermal shock resistance is poor, so as to achieve rich and uniform gradient pores The effect of structure, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

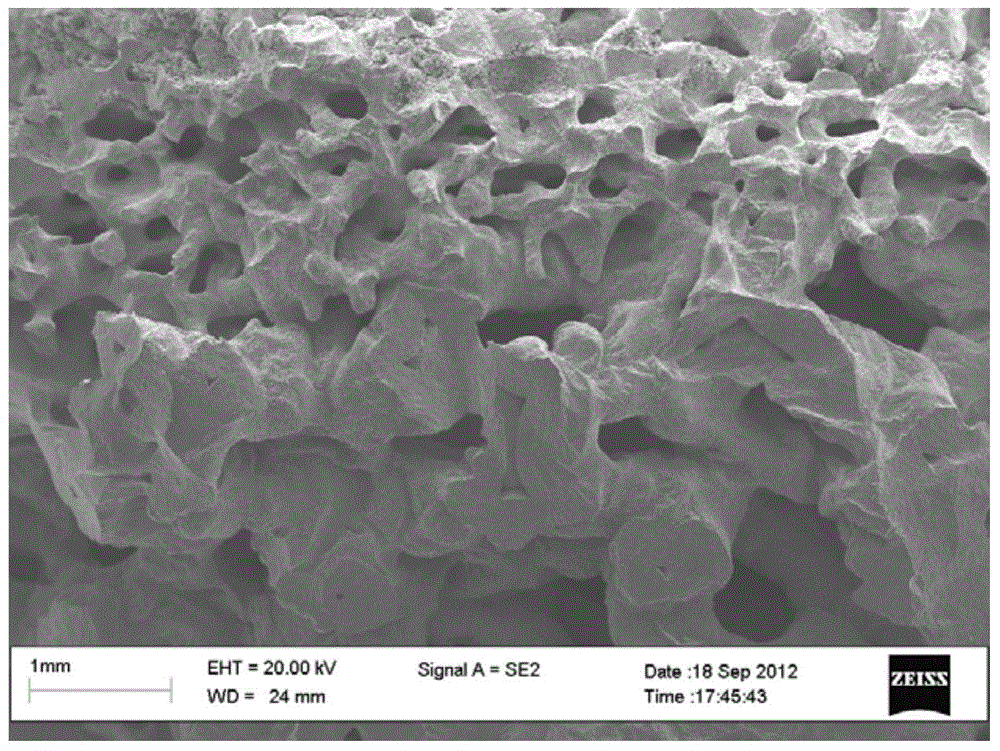

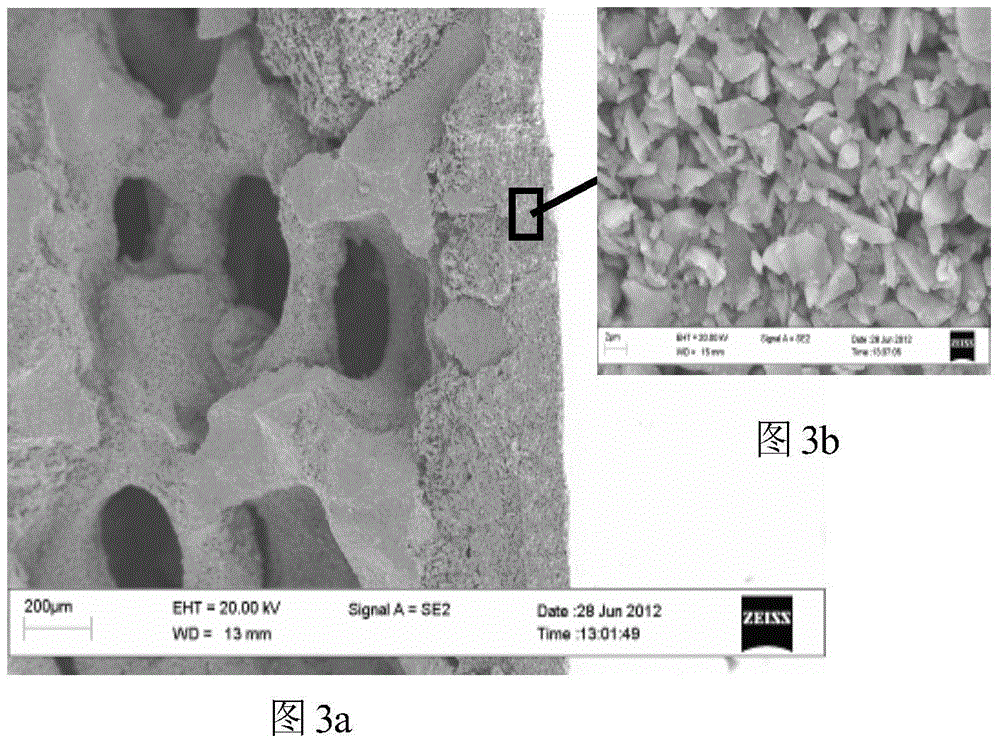

[0059] The preparation method of the pure foamed silicon carbide support film tube with three gradient pore structures of the present invention uses solid powder particles, organic polymer resin, curing agent, and organic solvent as basic materials, mixes and prepares slurry, and uses organic foam as a template, Prepare the support body precursor by impregnation method, carbonize and sinter at low temperature, infiltrate and sinter after processing and molding, and then purify at high temperature to obtain pure foam silicon carbide support with double gradient pore structure, use silicon carbide powder, silicon powder or silicon oxide powder, Pore-forming agent additives and organosilicon precursors are used to prepare the film layer raw materials, and the film layer is prepared on the surface by spraying or dipping. After drying, the finished film tube is obtained by sintering. The specific preparation steps are as follows:

[0060] (1) Raw material preparation for support mol...

Embodiment 1

[0082] Blend 5 μm silicon carbide powder, phenolic resin, p-toluenesulfonic acid, and ethanol in a mass ratio of 5:2:0.1:0.3, and ball mill after mechanical stirring to obtain a foam support body forming slurry.

[0083] Three types of polyurethane foam with pore diameters of 1mm, 2mm, and 3mm are selected as the inner layer, and cut into hollow cylinders with an outer diameter of Φ56mm (inner diameter Φ40mm)×300mm, and polyurethane foam with three pore sizes of 300μm, 400μm, and 500μm is used as the outer layer, and cut into an outer diameter of Φ60mm (Φ56mm) × 300mm hollow cylinder, the inner and outer polyurethane foams of different pore diameters are covered together to obtain 9 kinds of combined double-gradient organic foams (respectively 1mm and 300μm, 2mm and 300μm, 3mm and 300μm, 1mm and 400μm, 2mm and 400μm, 3mm and 400μm, 1mm and 500μm, 2mm and 500μm, 3mm and 500μm), impregnated into the molding slurry, centrifuged to remove excess slurry, dried and solidified at 120°...

Embodiment 2

[0088] The difference from Example 1 is that 10 μm silicon carbide powder, epoxy resin, urotropine, and formaldehyde are blended in a mass ratio of 4:1:0.2:0.2, and after mechanical stirring, ball milling to obtain a foam support body molding slurry material.

[0089] Select the same combination of several polyurethane foams as in Example 1, process and bond after dipping and molding, and pyrolysis and sintering.

[0090] The pyrolysis temperature is 1200°C, the heating rate is 1°C / min, and the protective atmosphere is argon. After natural cooling, it is taken out and put into the sintering furnace; the raw material selected in the infiltration reaction sintering is silicon, and the sintering and silicon infiltration are carried out under the condition of argon. The heating rate was 10° C. / min, the melt temperature was 1600° C., and the temperature was kept for 5 hours to obtain an impure foamed silicon carbide membrane tube support.

[0091] High-temperature purification tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com