Method for preparing nano porous copper thin film material by magnetron sputtering

A nanoporous copper and magnetron sputtering technology, applied in sputtering plating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of complex steps, poor conductivity, limited use, etc., and achieve simple preparation methods , controllable size and continuous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

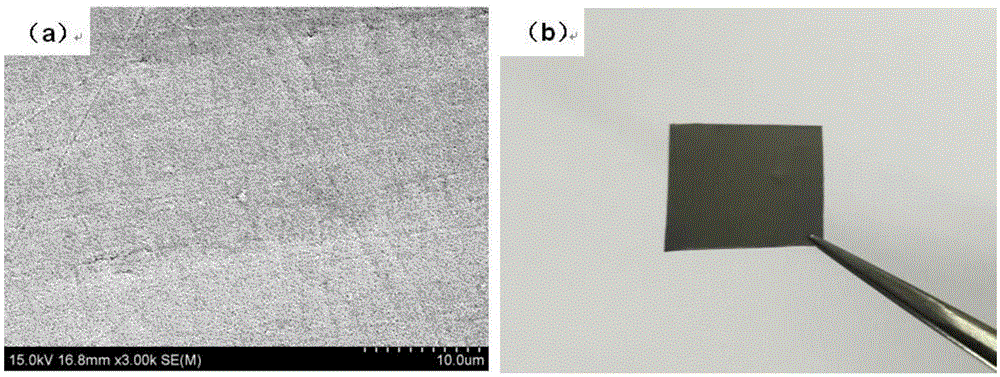

Image

Examples

Embodiment 1

[0050] Implementation Example 1: The base copper foil used in the experiment is a commercially produced copper foil with a copper content of more than 96%.

[0051] Cut the purchased commercial copper foil into a size of 5×5cm, flatten it and remove the edge burrs. Use crystal phase flannelette and crystal phase polishing agent to polish the surface of copper foil to make it rough. The velvet cloth of the crystal phase polishing agent, press the copper foil and move it back and forth, left and right, so that there is moving friction between the copper platinum and the flannelette, and polish for about 5 minutes, during which time the crystal phase polishing agent needs to be sprayed 1 or 2 times. Clean the polished copper foil with alcohol ultrasonically for 5 minutes to remove the crystal phase polishing agent remaining on the surface, and repeat the cleaning 2 to 3 times until the polishing agent is completely cleaned. The copper foil obtained in the previous step was ultra...

Embodiment 2

[0052] Implementation example 2: The equipment used in the laboratory is the TRP-450 high-vacuum three-target magnetron coating system produced by Shenyang Scientific Instruments, Chinese Academy of Sciences. The coating quality is good and the operation is simple.

[0053] Transfer the cleaned copper foil to the sample base of the equipment, turn on the mechanical pump to pre-evacuate to 20Pa, turn on the molecular pump to start high vacuum, and after 3 hours, the molecular pump can pump the air pressure of the reaction chamber to 8×10 -5 , to achieve the vacuum conditions required for the experiment. Continuing from the previous step, open the argon gas flow valve to control the flow rate at 20 sccm, and then pass the gas for 5 minutes to control the chamber pressure to 1.0Pa through the plate valve. After you are ready, turn on the substrate selection switch and control the substrate speed at 24r / min. Turn on the sputtering power supply, adjust the copper target sputtering ...

Embodiment 3

[0054] Implementation Example 3: The annealing equipment used in the experiment is the TRP-450 high-vacuum three-target magnetron coating system of Shenyang Scientific Instruments of the Chinese Academy of Sciences with a built-in substrate heating function. The dealloying step is carried out in a water bath by controlling the temperature.

[0055] After the co-sputtering of the copper target and the aluminum target is completed, turn on the substrate heating power, adjust to the preset temperature of 450°C, and at the same time control the argon gas flow rate to 10 sccm, turn on the heating start button to start heating, and when it reaches the preset temperature of 450°C, time it for 2 hours . After heating and annealing, turn off the heating power supply, wait until the sample cools to room temperature, turn off the sputtering equipment, and take out the obtained sample. Cut the sample obtained in the previous step into a size of 1×0.5cm, prepare a 1mol / L hydrochloric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com