Polymer optical fiber panel, manufacturing method and large-area polymer optical fiber panel

A fiber optic panel, polymer technology, applied in the direction of bundled optical fibers, etc., to achieve the effect of stable internal structure, high resolution and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific content of the present invention is further described below:

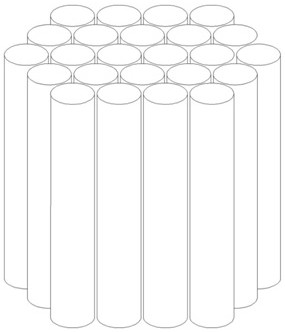

[0032] The present invention is an optical fiber panel made of polymer. The overall structure is a regular polygon, and the inside is a polymer optical fiber monofilament arranged in an array. The polymer optical fiber monofilament includes a polymer core material and a polymer core material wrapped Polymer skin with polymer core at the center, polymer skin wrapping the polymer core. The polymer core material is PMMA, and the polymer skin material is fluororesin.

[0033] The manufacturing process of polymer optical fiber panels adopts high-precision melt spinning machine to spin polymer optical fiber monofilaments, arrange them in a regular matrix, fuse them into a prefabricated rod, draw optical fiber multifilaments, arrange the plates, and vacuum melt and press them into polymer optical fiber array plates. section, and then perform optical finishing treatment, and finally produce a finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com