Compact inductor and load integrated gas switch

A technology for inductive loads and gas switches, which is applied to electrical components, circuits, corona discharge devices, etc., can solve the problems of large switch circuit volume insulators, unacceptable technical manufacturing costs, and increased manufacturing costs, so as to ensure the insulation strength of the electric field , compact structure, and improved insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described below in conjunction with accompanying drawing:

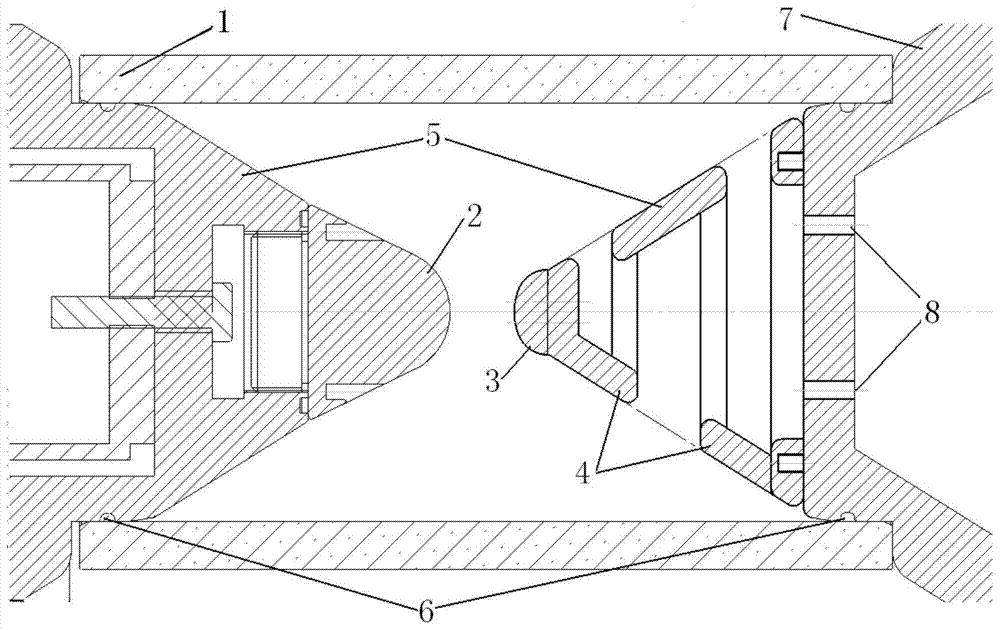

[0039] Such as figure 1 As shown, the compact inductive load integrated gas switch of the present invention adopts a two-electrode, self-breakdown structure. The anode electrode tip 3, the cathode electrode tip 2 and the outer insulating cylinder 1 form a main electrode cavity, which is sealed and filled with high-voltage insulating gas. The electrodes are machined from high conductivity, non-ferromagnetic brass material. The surface of the tip of the switch electrode transitions smoothly, forming a slightly uneven electric field with an electric field unevenness coefficient less than 2. The outer insulation cylinder of the switch is made of vacuum-impregnated glass fiber reinforced plastic cylinder with high mechanical strength and good insulation performance. The outer insulating cylinder is installed on the extension section of the load cone through the axial pressure tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com