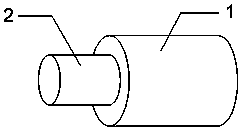

A core-shell nanofiber scaffold and its method for constructing tissue engineering materials with melanocytes

A nanofiber, core-shell type technology, applied in the field of biomedicine, can solve the problem that human melanocytes cannot be cultured, and achieve the effect of good mechanical properties, good shape, and maintaining activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1. Preparation of chitosan-polyethylene oxide core-shell nanofiber scaffold material

[0048] A. chitosan is dissolved with trifluoroacetic acid / dichloromethane weight ratio 3:1 mixed solvent, is made into the shell solution that concentration is 5%;

[0049] B. Dissolve polyethylene oxide, polyethylene glycol methacrylate, and polyethylene glycol dimethacrylate in water at a weight ratio of 80:20:1 to form a 5% nuclear layer solution , add 1% photoinitiator 1-[4-(2-hydroxyethoxy) phenyl]-2-hydroxyl-2 methyl-1-propane-1-one before spinning;

[0050] C. Electrospinning is carried out under the conditions of voltage of 15KV, core-shell propulsion rate of 0.5ml / h, receiving distance of 15cm, temperature of 30ºC, and ultraviolet light irradiation;

[0051] D. Bake the core-shell nanofiber support under vacuum at 50°C for 12 hours;

[0052] E. At 20ºC, the core-shell nanofiber scaffold was cross-linked with sodium sulfate for 2 hours, and after the cross-linking...

Embodiment 2

[0056] Example 2. Preparation of chitosan-polyvinylpyrrolidone core-shell nanofiber scaffold material

[0057] A. Dissolve chitosan with acetic acid / water (weight ratio 1:1) mixed solvent to make a chitosan solution with a concentration of 2%;

[0058] B. Dissolve polyvinylpyrrolidone, hydroxyethyl methacrylate, and N,N'-methylenebisacrylamide in water at a weight ratio of 70:30:3 to form a 9% nuclear layer solution. Add 3% photoinitiator phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide before spinning;

[0059] C. Electrospinning is carried out at a voltage of 20KV, a shell-layer propulsion rate of 0.5ml / h, a core-layer propulsion rate of 1ml / h, a receiving distance of 18cm, a temperature of 20ºC, and ultraviolet light;

[0060] D. The chitosan / polyethylene oxide-polyvinylpyrrolidone core-shell nanofiber scaffold was baked under vacuum at 25°C for 24 hours;

[0061] E. At 20ºC, the chitosan-polyvinylpyrrolidone core-shell nanofiber scaffold was cross-linked with genipin f...

Embodiment 3

[0065] Example 3. Preparation of gelatin-polyvinyl alcohol core-shell nanofiber scaffold material

[0066] A. Dissolve the gelatin with trifluoroethanol / water (mass ratio 8:2) to make a 10% gelatin solution;

[0067] B. Dissolve polyvinyl alcohol, methacrylic acid, and ethylene glycol dimethacrylate in acetic acid / water (mass ratio 1:1) at a weight ratio of 60:40:0.4, and the concentration is 3%. The core layer solution, add 0.2% photoinitiator 2-hydroxyl-1-[4-(hydroxyl) phenyl]-2-methyl-1-propanone before spinning;

[0068] C. Electrospinning is carried out at a voltage of 25KV, a shell layer propulsion rate of 1ml / h, a core layer propulsion rate of 0.5ml / h, a receiving distance of 20cm, a temperature of 40ºC, and ultraviolet light;

[0069] D. Bake the gelatin-polyethylene glycol nanofiber scaffold under vacuum at 25°C for 24 hours;

[0070]E. At 50ºC, the gelatin-polyvinyl alcohol core-shell nanofiber scaffold was cross-linked with glutaraldehyde for 12 hours, and after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com