Preparation method of magnetic-functionalized graphene composite material

A composite material and magnetic function technology, which is applied in chemical instruments and methods, carbon compounds, and the magnetism of inorganic materials, can solve the problems of unfavorable expansion of production and cumbersome preparation process, and achieve easy industrial production, simple preparation process, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Prepare 50 mL of ethylenediamine / water mixed solvent (9:1 by volume).

[0031] 2) Weighing 50 mg of graphite oxide and 50 mg of ferric acetylacetonate were dispersed in the mixed solvent of step 1), and ultrasonically dispersed for 15 h; the mass ratio of graphite oxide to ferric acetylacetonate was 1:1;

[0032] 3) The mixed solution obtained in step 2) was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 200° C. for 24 hours.

[0033] 4) Cool to room temperature after the reaction, and pour out the product in the polytetrafluoroethylene lining. The obtained solid is washed with water and ethanol solution several times, and then the product is collected by a magnet, and the sample is dried to obtain a magnetically functionalized graphene composite material.

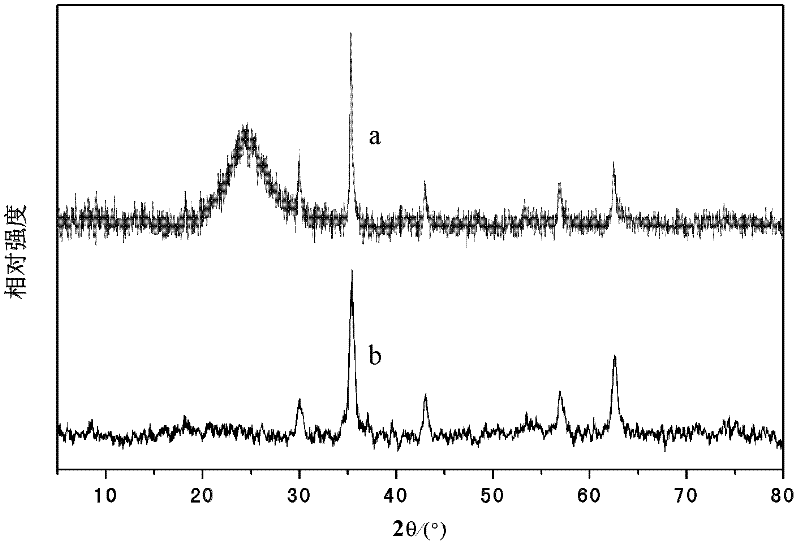

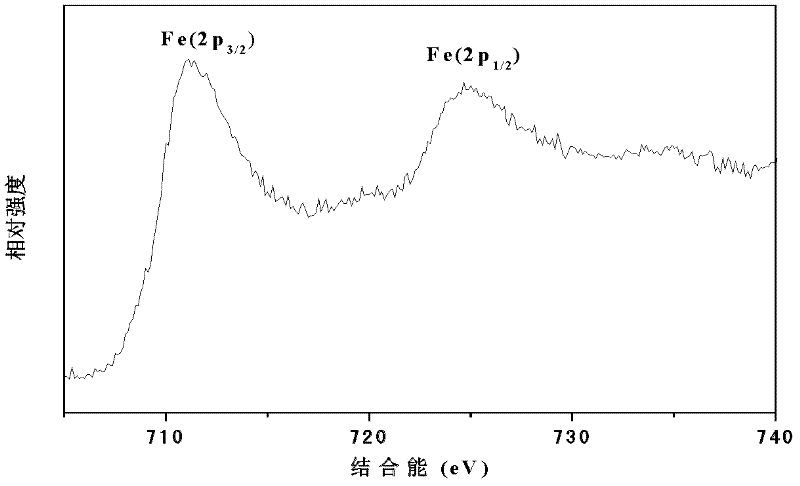

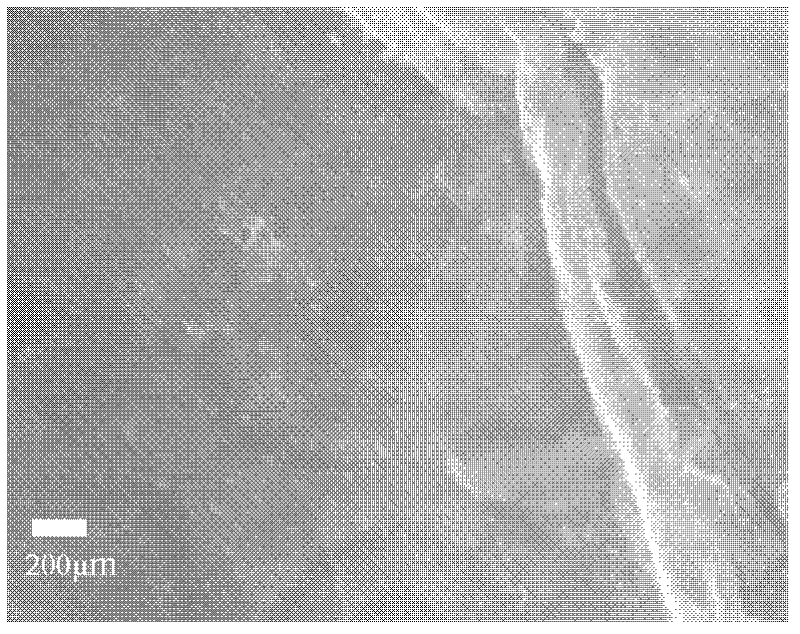

[0034] The magnetically functionalized graphene composite material sample obtained in this embodiment is characterized by various items, and the characterization results can be found in...

Embodiment 2

[0041] 1) Prepare 50mL ethylenediamine / water mixed solution (volume ratio is 9:1).

[0042] 2) Weigh 70 mg of graphite oxide and 30 mg of iron acetylacetonate and disperse them in the mixed solvent of step 1), and disperse them ultrasonically for 15 hours; the mass ratio of graphite oxide to iron acetylacetonate is 7:3.

[0043]3) The mixed solution obtained in step 2) was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 200° C. for 24 hours.

[0044] 4) Cool to room temperature after the reaction, and pour out the product in the polytetrafluoroethylene lining. The obtained solid is washed with water and ethanol solution several times, and then the product is collected by a magnet, and the sample is dried to obtain a magnetically functionalized graphene composite material.

[0045] The obtained magnetic functionalized graphene composite material sample in the present embodiment, its X-ray diffraction figure and energy spectrum analysis result are ident...

Embodiment 3

[0049] 1) Prepare 50mL ethylenediamine / water mixed solution (volume ratio is 9:1).

[0050] 2) Weigh 90 mg of graphite oxide and 10 mg of iron acetylacetonate and disperse them in the mixed solvent of step 1), and disperse them ultrasonically for 15 hours; the mass ratio of graphite oxide to iron acetylacetonate is 9:1.

[0051] 3) The mixed solution obtained in step 2) was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 200° C. for 24 hours.

[0052] 4) Cool to room temperature after the reaction, and pour out the product in the polytetrafluoroethylene lining. The obtained solid is washed with water and ethanol solution several times, and then the product is collected by a magnet, and the sample is dried to obtain a magnetically functionalized graphene composite material.

[0053] The obtained magnetic functionalized graphene composite material sample in the present embodiment, its X-ray diffraction figure and energy spectrum analysis result are iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com