A kind of magnetic composite microsphere and its preparation method and application

A technology of magnetic composite microspheres and stirring reaction, which is used in the preparation of microspheres, biochemical equipment and methods, magnetic objects, etc., to achieve good reusability, improved temperature stability, improved enzymatic activity recovery ability and temperature stability performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

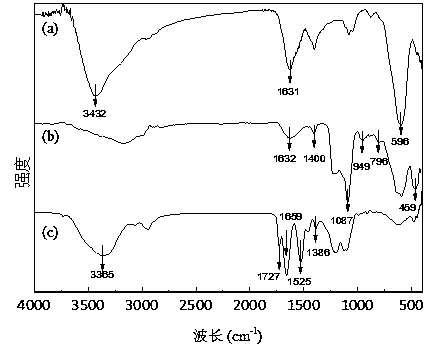

Image

Examples

Embodiment 1

[0043] Example 1: Fe 3 o 4 Synthesis

[0044] Dissolve 1.350g of ferric chloride hexahydrate in 70mL of ethylene glycol, add 3.854g of ammonium acetate and 0.400g of trisodium citrate, stir for 1 hour at an oil bath temperature of 170°C until the solution becomes a uniform system, and transfer to a polytetrafluoroethylene lining Heated to 200°C for 16h in a stainless steel reactor. Cool to room temperature after taking out, magnetically separate the product, wash with ethanol until the supernatant is transparent, and dry in a vacuum oven at 50°C until constant weight.

Embodiment 2

[0045] Example 2: Fe 3 o 4 @SiO 2 Synthesis of -p(GMA-co-NIPAM)

[0046] (1) Fe 3 o 4 @SiO 2 - Synthesis of MPS

[0047] The product Fe in the embodiment 1 of 0.1 g 3 o 4 Disperse in 15 mL of a mixed solution of ethanol and water with a volume ratio of 4:1, then add 1 mL of ammonia solution, stir mechanically and slowly add 0.5 mL of TEOS dropwise into the system, and react at room temperature for 6 hours. 0.3mL MPS was added into the system, and the stirring reaction was continued for 12 hours. The product was separated magnetically and washed several times with ethanol. Dry to constant weight in a vacuum oven at 50°C.

[0048] (2) Fe 3 o 4 @SiO 2 Synthesis of -p(GMA-co-NIPAM)

[0049] Take 50mg Fe 3 o 4 @SiO 2 - Add MPS to a one-necked flask, add 40mL acetonitrile for ultrasonic dispersion for 3min, add 50 mgNIPAM, 0.05mL GMA, 100mg cross-linking agent MBA, 4mg initiator AIBN, heat the flask in an oil bath, install a fractionation column, a condenser...

Embodiment 3

[0050] Example 3: Fe 3 o 4 @SiO 2 Synthesis of -p(GMA-co-NIPAM)

[0051] (1) Fe 3 o 4 @SiO 2 - Synthesis of MPS

[0052] The product Fe in the embodiment 1 of 0.5 g 3 o 4 Disperse in 90 mL of a mixed solution of ethanol and water with a volume ratio of 4:1, then add 3 mL of ammonia solution, stir mechanically and slowly add 1.2 mL of TEOS dropwise into the system, and react at room temperature for 24 hours. 1.5 mL of MPS was added to the system, and the stirring reaction was continued for 48 hours. The product was separated magnetically and washed several times with ethanol. Dry to constant weight in a vacuum oven at 50°C.

[0053] (2) Fe 3 o 4 @SiO 2 Synthesis of -p(GMA-co-NIPAM)

[0054] Take 100mg Fe 3 o 4 @SiO 2 - Add 80mL of acetonitrile to ultrasonically disperse MPS for 3 minutes, add 150mg of NIPAM, 0.15mL of GMA, 200mg of cross-linking agent MBA, 10mg of initiator AIBN, heat the flask in an oil bath, install a fractionating column, a condenser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com