Water-based environment-friendly film-forming material applied in steel fastener surface, and preparation method and application thereof

A technology of film-forming materials and fasteners, which is applied in the field of water-based environment-friendly film-forming materials and its preparation, to achieve the effects of high temperature resistance, high hardness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

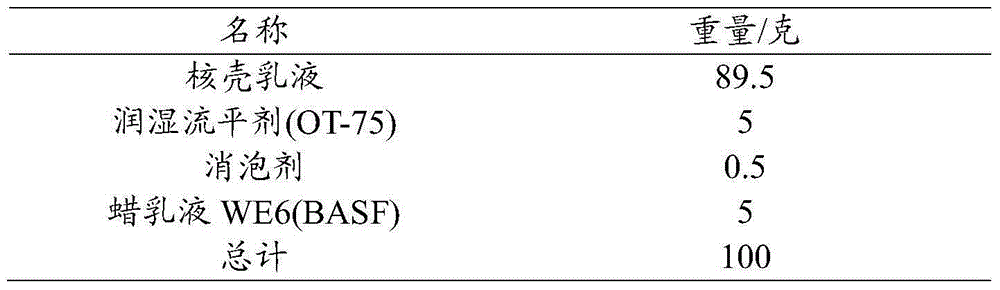

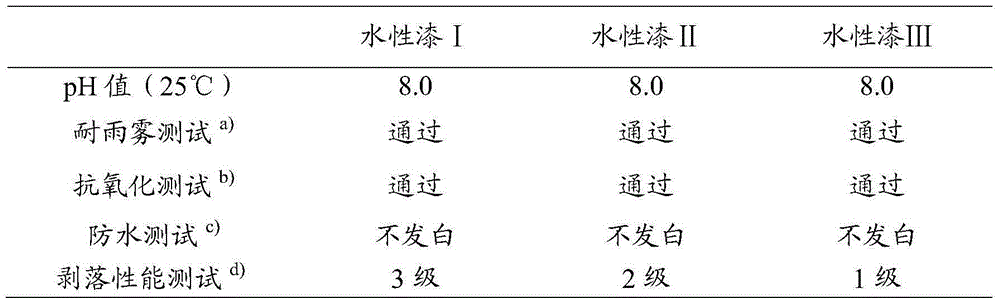

Examples

preparation example Construction

[0037] The invention provides a water-based environment-friendly film-forming material applied to the surface of steel fasteners and its preparation method and application. The preparation method of the water-based environment-friendly film-forming material applied to the surface of steel fasteners comprises the following steps:

[0038] A method for preparing a water-based environment-friendly film-forming material applied to the surface of a steel fastener, comprising the following steps:

[0039] 1) Synthesis of shell emulsion: get 20-30 parts of vinyl monomer I, 0.5-1.5 parts of initiator, 1-3 parts of molecular weight adjustment, 0.5-1.5 parts of composite emulsifier, 1-3 parts of pH Regulator and make up to 100 parts of water, react to make shell emulsion;

[0040] 2) Synthesis of core-shell emulsion: Add 1-2 parts of initiator and 50-90 parts of vinyl monomer II to the shell emulsion obtained in step 1), and react to obtain core-shell emulsion, which is applied to steel...

Embodiment 1

[0061] 1) Synthesis of shell emulsion:

[0062] i) Dissolving 8 grams of ammonium persulfate in 1158 grams of water and raising the temperature to 83° C., feeding nitrogen gas for 30 minutes to remove oxygen to obtain an initiator solution;

[0063] ii) Add 500 grams of deionized water, 2 grams of sodium acrylamido isopropyl sulfonate, 8 grams of branched chain alkyl alcohol polyoxyethylene ether phosphoric acid monoester, 272 grams of methyl methacrylate, 48 grams of N-methylolacrylamide, 40 grams of methacrylic acid, 50 grams of butyl methacrylate, 50 grams of acrylate-β-hydroxypropyl ester, and 20 grams of 3-mercaptopropanol are pre-emulsified to obtain a pre-emulsified solution;

[0064] iii) Add the pre-emulsified solution dropwise to the initiator solution at 80-85°C by "starvation method" for 90 minutes to react, add ammonia water to adjust the pH to 7.5-8.0, and keep it warm for 30 minutes to obtain the shell emulsion;

[0065] 2) Synthesis of core-shell emulsion:

...

Embodiment 2

[0069] 1) Synthesis of shell emulsion:

[0070] i) Dissolving 8 grams of ammonium persulfate in 1158 grams of water and raising the temperature to 83° C., feeding nitrogen gas for 30 minutes to remove oxygen to obtain an initiator solution;

[0071] ii) Add 500 grams of deionized water, 4 grams of sodium alkenyl phosphate, 6 grams of branched chain alkyl alcohol polyoxyethylene ether phosphoric acid monoester, 272 grams of methyl methacrylate, 48 grams of (meth)acrylic acid in the head tank Glycidyl ester, 40 grams of carboxyethyl acrylate (β-CEA), 50 grams of butyl methacrylate, 50 grams of methacrylate-β-hydroxypropyl ester, and 20 grams of 3-mercaptopropanol were pre-emulsified to obtain pre-emulsified emulsified solution;

[0072] iii) Add the pre-emulsified solution dropwise to the initiator solution at 80-85°C by "starvation method" for 90 minutes to react, add ammonia water to adjust the pH to 7.5-8.0, and keep it warm for 30 minutes to obtain the shell emulsion;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com