Laser cladding tungsten carbide ceramic particle reinforced metal-based coating and its processing method

A technology of cladding tungsten carbide ceramics and particle reinforcement, which is applied in the direction of metal material coating process and coating, and can solve the problems of poor bonding between the reinforcement phase and the matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

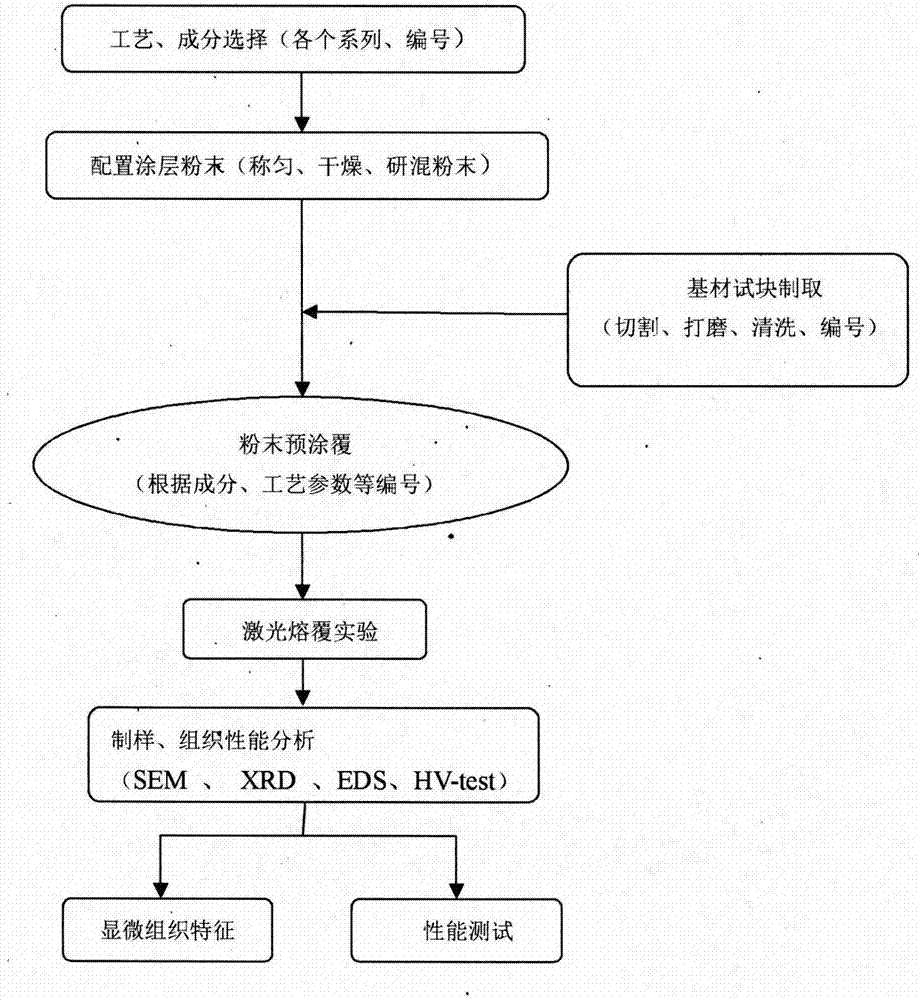

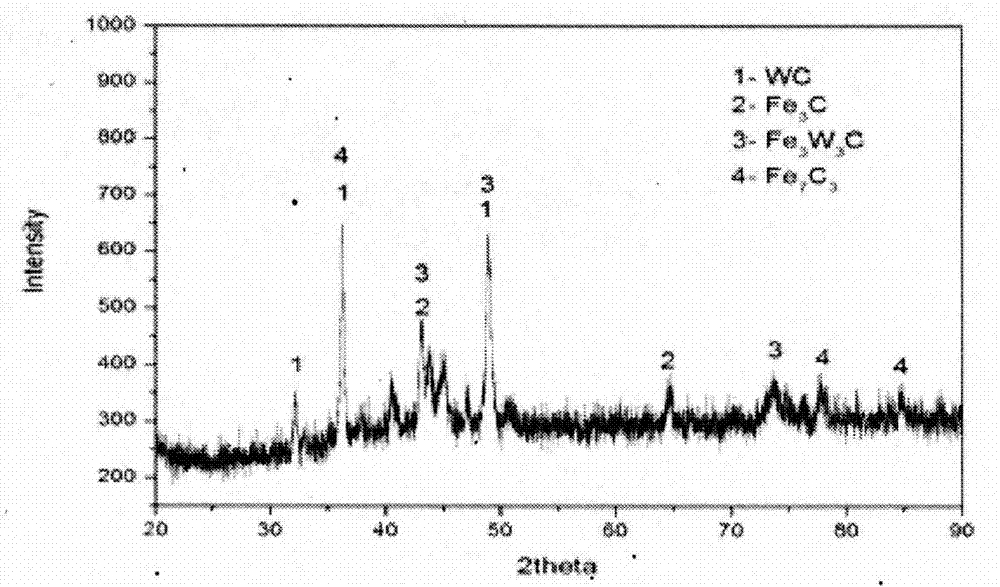

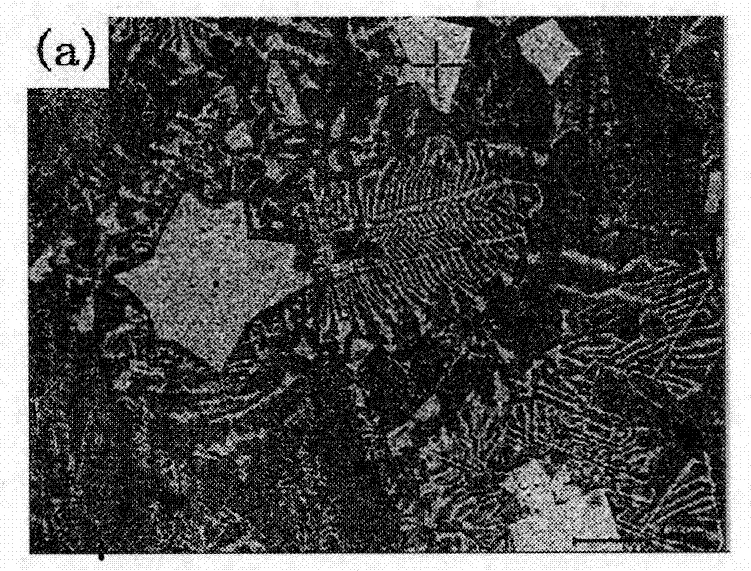

[0034] Specific embodiments of the present invention such as Figure 1-20 Shown is a laser cladding tungsten carbide ceramic particle reinforced metal-based coating, which includes alloy powder, the alloy powder includes tungsten powder and graphite with a molar ratio of 2:1, and the alloy powder also includes reduced iron powder, chromium powder, and nickel powder , boron powder, silicon powder and copper powder, as a preferred solution, the composition and percentage mass ratio of the alloy powder are: tungsten powder 60%, graphite 8%, reduced iron powder 27%, chromium powder 1%, nickel powder 3% , boron powder 0.5%, silicon powder 0.5%, copper powder 0.5%. Preferably, 0.5% of rare earth oxide powder such as cerium oxide can also be added to the alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com