Preparation of low-temperature NH3-SCR catalyst with slice-shaped V2O5/TiO2 as carrier and application of catalyst in denitration

A technology of NH3-SCR and catalyst, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, perfluorocarbon/hydrofluorocarbon capture, etc., to achieve good low-temperature denitrification efficiency, The effect of low temperature and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

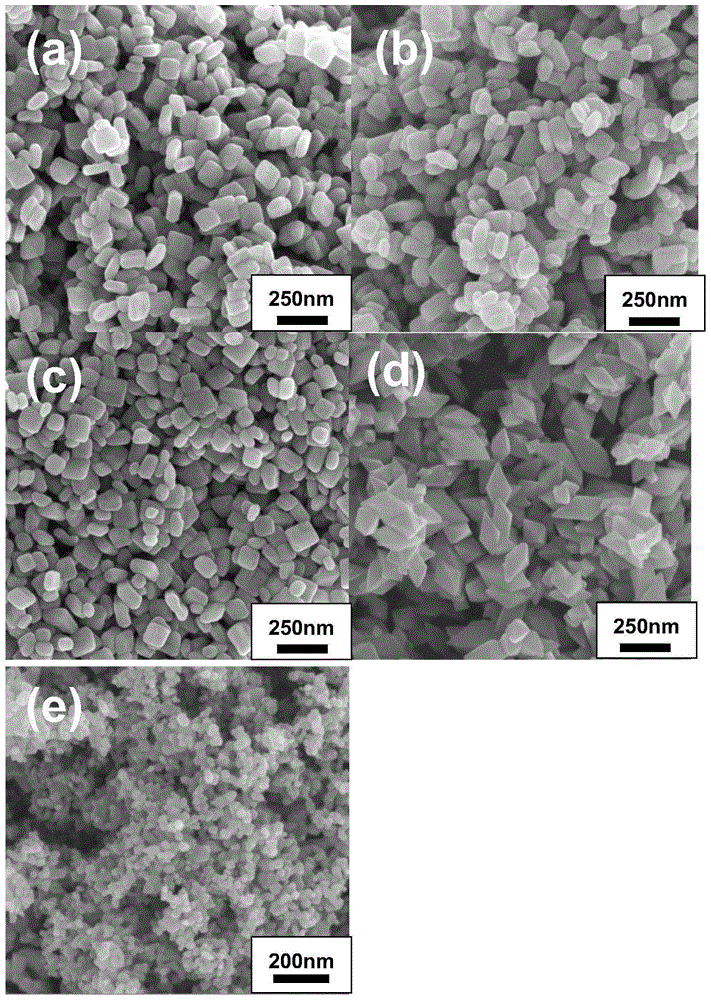

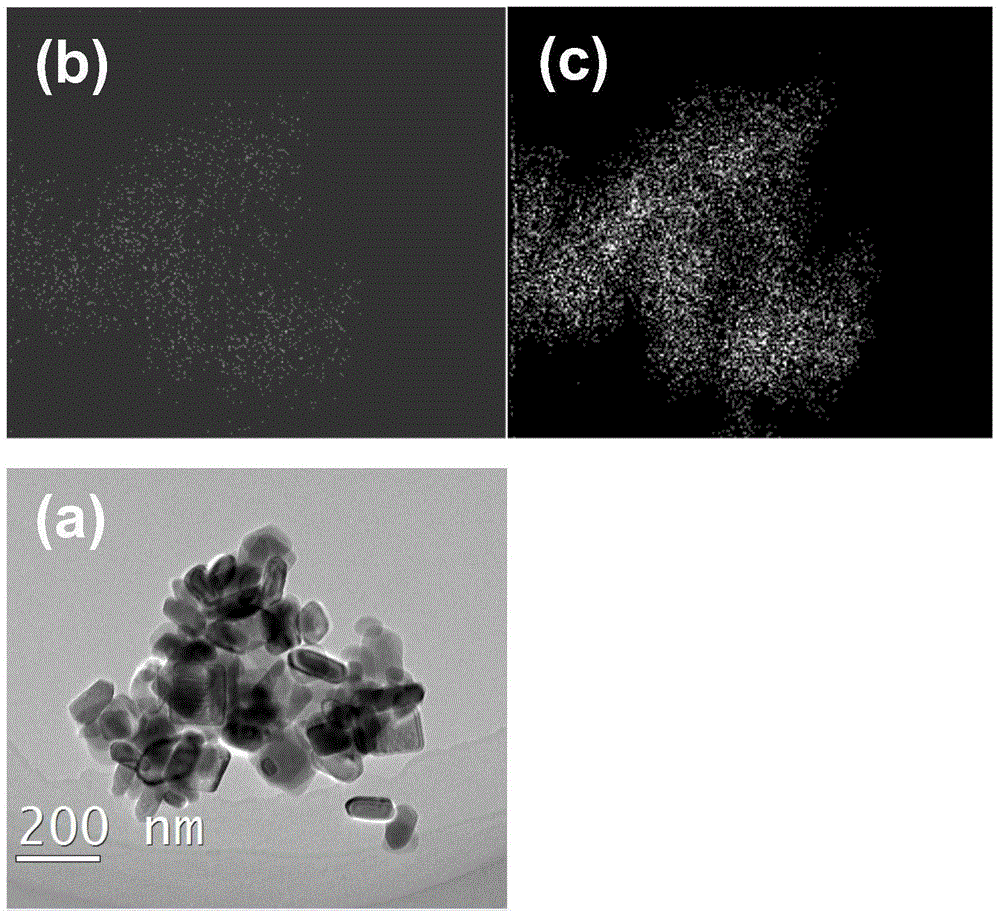

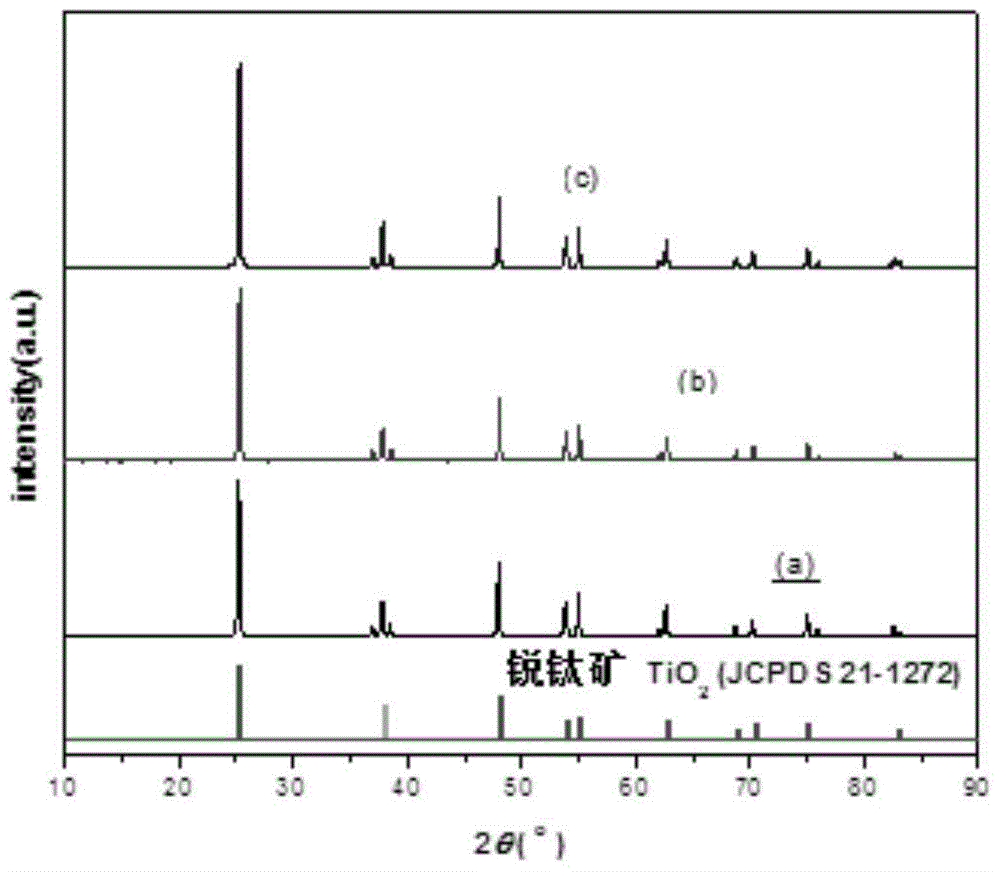

[0031] (1) Flake TiO 2 Preparation of carrier: Add 18ml of hydrogen peroxide aqueous solution (30%wt) and 3ml of hydrofluoric acid solution (40%wt) mixture dropwise to 15ml of butyl titanate under stirring. The mixture was transferred into a 100ml teflon liner. After loading into a stainless steel autoclave, keep it in a blast drying oven at 200°C for 24h, and then cool to natural room temperature. The final product was suction filtered, washed several times with deionized water and alcohol, and then dried at room temperature. get flake TiO 2 carrier.

[0032] (2) Active ingredient V 2 o 5 Loading: Dissolve oxalic acid with deionized water in a 60°C water bath, and then add ammonium metavanadate to the oxalic acid solution until completely dissolved. Finally, the flake-like TiO 2 The samples were immersed in the above solutions. After magnetic stirring for 2h, sonication for 2h. Then, the catalyst samples were dried in a blast oven at 110°C for 5 hours and then calcin...

Embodiment 2

[0035] (1) Flake TiO 2 Preparation of carrier: Add 20 ml of hydrogen peroxide aqueous solution (30%wt) and 2ml of hydrofluoric acid solution (40%wt) mixture dropwise to 16ml of butyl titanate under stirring. The mixture was transferred into a 100ml teflon liner. After loading into a stainless steel autoclave, keep it in a blast drying oven at 200°C for 20h, and then cool to natural room temperature. The final product was suction filtered, washed several times with deionized water and alcohol, and then dried at room temperature. get flake TiO 2 carrier.

[0036] (2) Active ingredient V 2 o 5 Loading: Dissolve oxalic acid with deionized water in a 60°C water bath, and then add ammonium metavanadate to the oxalic acid solution until completely dissolved. Finally, the flake-like TiO 2 The samples were immersed in the above solutions. After magnetic stirring for 1 h, ultrasonication for 3 h. Then, the catalyst samples were dried in a blast oven at 110°C for 7 hours and the...

Embodiment 3

[0038] (1) Flake TiO 2 Preparation of carrier: Add 20 ml of hydrogen peroxide aqueous solution (30%wt) and 2ml of hydrofluoric acid solution (40%wt) mixture dropwise to 16ml of butyl titanate under stirring. The mixture was transferred into a 100ml teflon liner. After loading into a stainless steel autoclave, keep it in a blast drying oven at 200°C for 20h, and then cool to natural room temperature. The final product was suction filtered, washed several times with deionized water and alcohol, and then dried at room temperature. get flake TiO 2 carrier.

[0039] (2) Active ingredient V 2 o 5 Loading: Dissolve oxalic acid with deionized water in a 60°C water bath, and then add ammonium metavanadate to the oxalic acid solution until completely dissolved. Finally, the flake-like TiO 2 The samples were immersed in the above solutions. After magnetic stirring for 1 h, ultrasonication for 3 h. Then, the catalyst samples were dried in a blast oven at 110°C for 7 hours and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com