UV cathode electrophoresis paint and coating process of same

A cathodic electrophoresis and process technology, applied in electrophoretic coatings, coatings and other directions, can solve the problems of increasing the difficulty and cost of processing, low utilization rate of original paint, harsh operating environment, etc., to simplify curing equipment, high utilization rate of coatings, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

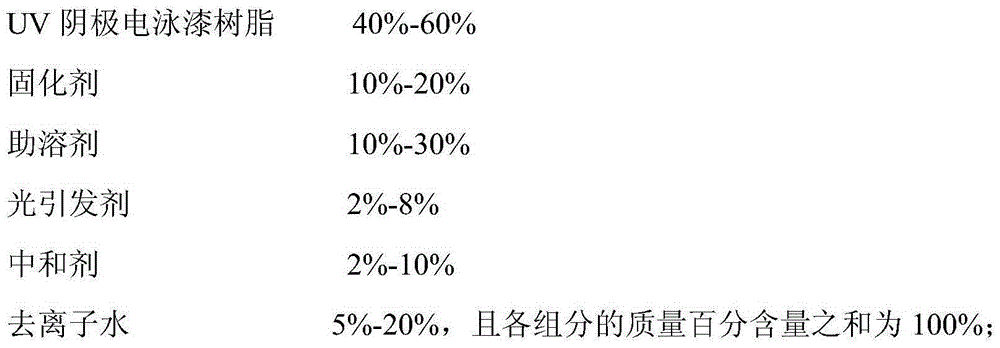

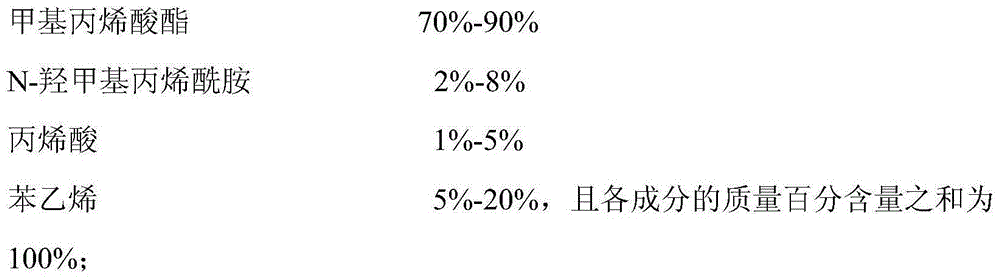

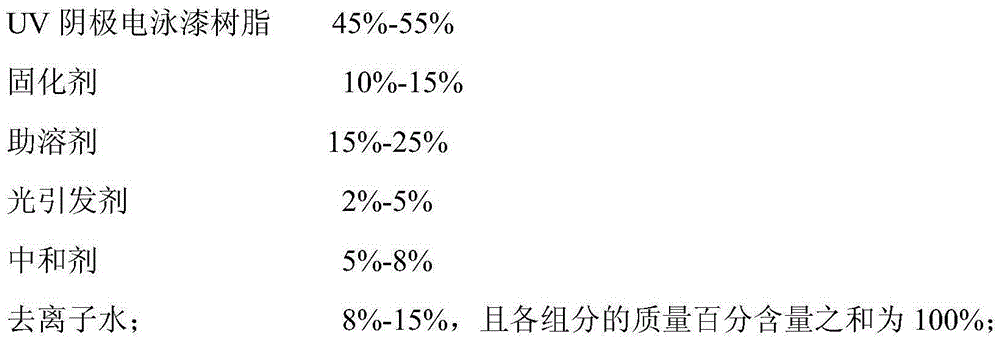

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1: zinc alloy substrate electrophoresis plus vacuum electroplating process steps:

[0087] (1) Ultrasonic (hot soak) degreasing and wax removal

[0088] Aqueous solution formula: sodium carbonate (Na 2 CO 3 ) 20g / L sodium silicate (Na 2 SiO 3 ) 20g / L Surfactant 1g / L Operating temperature: 40°C Time: until clean Equipment requirements: use with ultrasonic

[0089] (2) Cathodic electrolytic degreasing

[0090] Aqueous solution formula: sodium hydroxide (NaOH) 1g / L sodium carbonate (NaOH) 2 CO 3 ) 5g / L trisodium phosphate (Na 3 PO 4 ) 20g / L Surfactant 1g / L Operating temperature: 40℃ Cathode current density: 5A / dm 2 Time: 0.5min

[0091] (3) Washing

[0092] running water

[0093] (4) Film removal (light emitting)

[0094] Aqueous solution formula: nitric acid (HNO 3 ) 2% (weight percent) Temperature: room temperature Time: 2s

[0095] (5) Washing

[0096] running water

[0097] (6) Passivation

[0098] Aqueous solution formula: chromic anhydrid...

Embodiment 2

[0127] Embodiment 2: copper and copper alloy substrate electrophoresis plus vacuum electroplating process steps:

[0128] (1) Ultrasonic (hot soak) degreasing and wax removal

[0129] Aqueous solution formulation: Sodium Hydroxide (NaOH) 10g / L Sodium Carbonate (NaOH) 2 CO 3 ) 55g / L trisodium phosphate (Na 3 PO 4 ) 55g / L sodium silicate (Na 2 SiO 3) 7.5g / L Operating temperature: 75°C Time: until cleaning Equipment requirements: use with ultrasonic

[0130] (2) Cathodic electrolytic degreasing

[0131] Aqueous solution formulation: Sodium Hydroxide (NaOH) 7.5g / L Sodium Carbonate (NaOH) 2 CO 3 ) 15g / L sodium silicate (Na 2 SiO 3 ) 25g / L Surfactant 1.5g / L Operating temperature: 60℃ Cathode current density: 7.5A / dm 2 Time: 1.3min

[0132] (3) Washing

[0133] running water

[0134] (4) activation

[0135] Aqueous solution formula: concentrated sulfuric acid (H 2 SO 4 ) 7.5% (volume) Temperature: room temperature

[0136] (5) Washing

[0137] running water

[01...

Embodiment 3

[0166] Embodiment 3: pure aluminum substrate electrophoresis plus vacuum electroplating industrial steps:

[0167] (1) Ultrasonic (hot soak) degreasing and wax removal

[0168] Aqueous solution formula: sodium carbonate (Na 2 CO 3 ) 50g / L trisodium phosphate (Na 3 PO 4 ) 50g / L sodium silicate (Na 2 SiO 3 ) 30g / L Operating temperature: 80°C Time: until cleaning Equipment requirements: use with ultrasonic

[0169] (2) washing

[0170] running water

[0171] (3) Microetching

[0172] Aqueous solution formula: Sodium Hydroxide (NaOH) 80g / L Temperature: 70℃ Time: 30s

[0173] (4) Washing

[0174] running water

[0175] Aqueous solution formula: concentrated nitric acid (HNO 3 ) 500g / L Temperature: room temperature Time: 15s

[0176] (6)Washing

[0177] running water

[0178] (7) Anodizing

[0179] Aqueous solution formula: sulfuric acid (H 2 SO 4 ) 200g / L aluminum ion (Al 3+ ) 15g / L Temperature: 25°C Current Density 1.5g / L Voltage 20v Power Supply: DC Time: 40min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com