Recycled magnesia carbon coating material with strong slag-corrosion resistance and application thereof

A smear, magnesium carbon technology, used in the removal of solid waste, waste treatment and other directions, can solve the problems of reduced porosity, poor disintegration performance, steel infiltration, etc., to reduce production costs and prevent infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

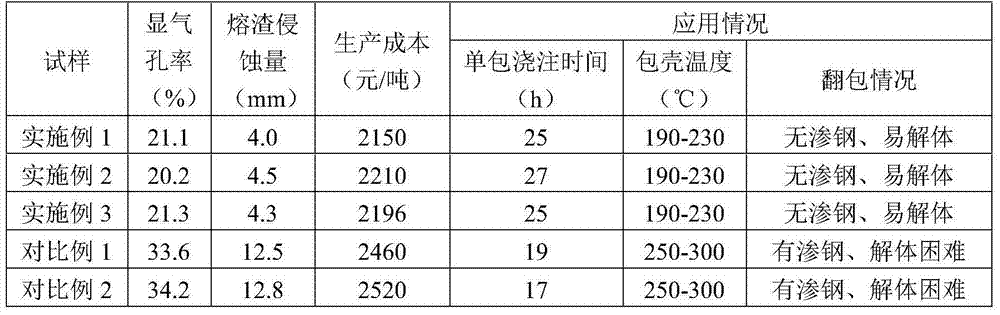

Embodiment 1

[0038] The regenerated magnesia-carbon smear material with strong anti-slag performance is composed of the following materials by weight percentage: 15% of regenerated granules of waste magnesia-carbon bricks with a particle size of 3mm2 o 3 Micropowder 3%, Al-Mg spinel micropowder with particle size ≦0.047mm 3.5%, soft clay 4.0%, silicon micropowder 2.0%, sodium tripolyphosphate 0.5%, metal silicon powder with particle size ≦0.074mm 0.5%, particle size ≦0.074 mm silicon carbide powder 1.2%, refractory fiber 0.3%, both are weight percentages.

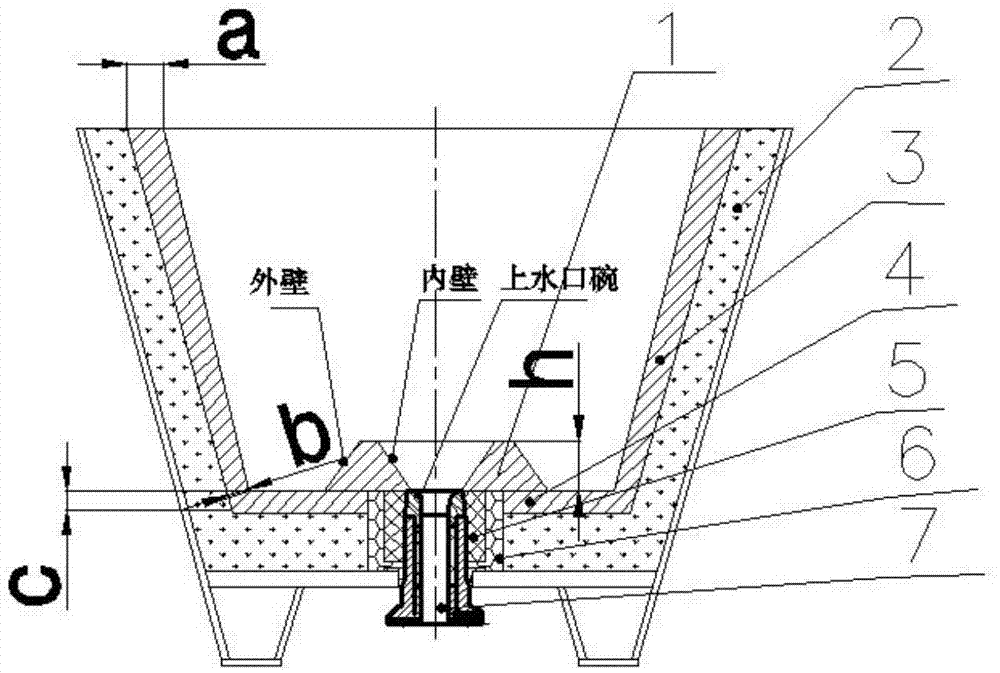

[0039] Such as figure 1 As shown, the regenerated magnesia-carbon smear material with strong slag resistance of the present invention is applied to the construction method of the continuous casting tundish working lining and the upper nozzle cofferdam, comprising the following steps:

[0040] 1) Preparation of regenerated magnesia carbonaceous smear material with strong anti-slag performance: after weighing the above materials accordin...

Embodiment 2

[0047] Others are the same as embodiment 1, the difference is:

[0048] The regenerated magnesia-carbon smear material with strong slag resistance is composed of the following materials in percentage by weight: 10% of regenerated granules of waste magnesia-carbon bricks with a particle size of 3mm2 o 3 Micropowder 5%, Al-Mg spinel powder 5.0% with particle size≦0.047mm, soft clay 3.5%, silicon micropowder 2.5%, sodium tripolyphosphate 0.2%, metal silicon powder with particle size≦0.074mm 1.0%, particle size≦0.074 mm silicon carbide powder 0.7%, refractory fiber 0.1%, both are weight percentages.

[0049] The construction method of applying the regenerated magnesia-carbon smear material with strong slag resistance performance of the present invention to the working lining of the continuous casting tundish and the cofferdam of the upper nozzle comprises the following steps:

[0050] 1) Preparation of regenerated magnesia carbonaceous smear material with strong anti-slag perform...

Embodiment 3

[0057] Others are the same as embodiment 1, the difference is:

[0058] The regenerated magnesia-carbon smear material with strong anti-slag performance is composed of the following materials by weight percentage: 13% of waste magnesia-carbon brick regenerated particles with a particle size of 3mm2 o 3 Micropowder 4%, Al-Mg spinel micropowder with particle size≦0.047mm 4.0%, soft clay 3.8%, silicon micropowder 1.5%, sodium tripolyphosphate 0.5%, metal silicon powder with particle size≦0.074mm 1.0%, particle size≦0.074 mm silicon carbide powder 1.0%, refractory fiber 0.2%, both are weight percentages.

[0059] The construction method of applying the regenerated magnesia-carbon smear material with strong slag resistance performance of the present invention to the working lining of the continuous casting tundish and the cofferdam of the upper nozzle comprises the following steps:

[0060] 1) Preparation of regenerated magnesia carbonaceous smear material with strong anti-slag pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com