Composition for preventing ionic migration and preparation method, non-gel substrate and preparation method

A technology of ion migration and composition, which is applied in the direction of circuit substrate materials, coatings, printed circuit components, etc., can solve problems such as small volume resistivity, sudden drop in bonding force of contact area, short circuit, etc., to meet performance requirements and prevent The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

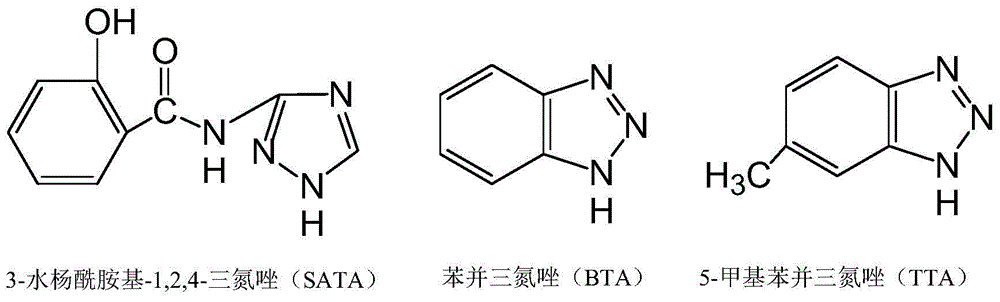

Problems solved by technology

Method used

Image

Examples

Embodiment 1

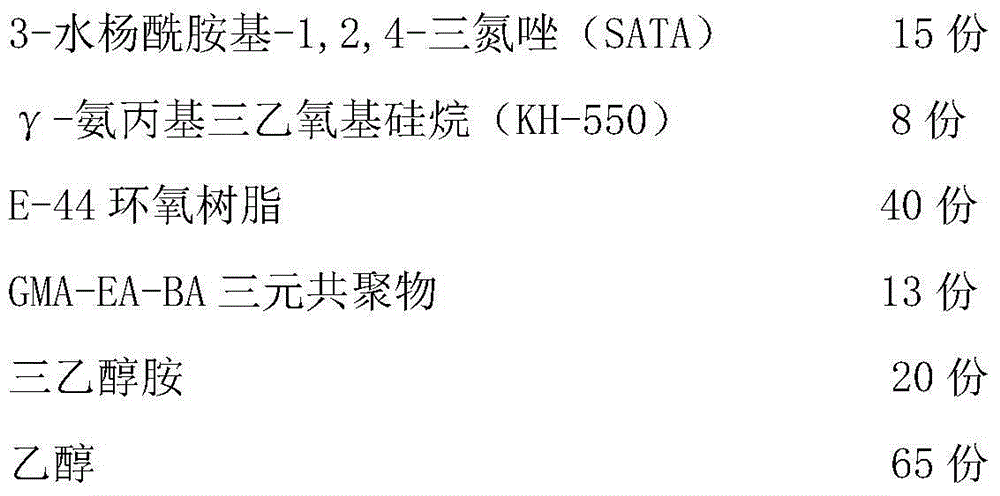

[0040] The formula that the composition that present embodiment prepares anti-ion migration adopts is as follows:

[0041]

[0042] According to the above formula, add 40g of E-44 epoxy resin and 13g of GMA-EA-BA terpolymer into 65g of ethanol. After stirring evenly, add 8g of KH-550 and 15g of SATA in turn, stir and dissolve Finally, add 20g of triethanolamine at last, stir to obtain a liquid mixture product with moderate viscosity, and seal it for future use.

[0043] The prepared anti-ion migration composition is coated on the roughened surface of the copper foil, and the thickness of the coating is about , baked at 60°C for 1 hour, the solvent evaporates and forms a film, and then coats polyimide precursor resin polyamic acid on it, the coating thickness is 20-30μm, and the polyimide is obtained after thermal imidization Imine copper clad laminate, that is, no adhesive substrate. Test the surface resistance, volume resistivity and peel strength of the polyimide film ...

Embodiment 2

[0049] The difference between this example and Example 1 is that 5-methylbenzotriazole (TTA) is used as the trapping cation exchanger, and the others remain unchanged.

[0050] The test result of embodiment two is as follows:

[0051] Surface resistance: 5.3×10 14 Ω;

[0052] Volume resistivity: 6.9×10 14 Ω.cm;

[0053] Peel strength: 1.71N / mm.

Embodiment 3

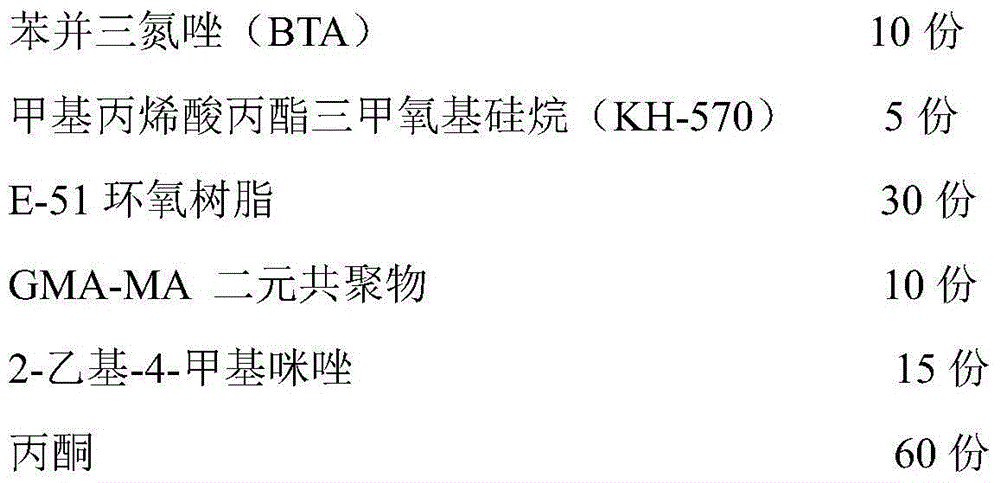

[0055] The formula that the composition that present embodiment prepares anti-ion migration adopts is as follows:

[0056]

[0057] According to the above formula, add 30g of E-51 epoxy resin and 10g of GMA-MA binary copolymer into 60g of acetone. After stirring evenly, add 5g of KH-570 and 10g of BTA in turn, and stir to dissolve. Finally, add 15g of 2-ethyl-4-methylimidazole, stir evenly to obtain a liquid mixture product with moderate viscosity, and seal it for future use.

[0058] The prepared anti-ion migration composition is coated on the roughened surface of the copper foil, and the thickness of the coating is about , baked at 60°C for 1 hour, the solvent evaporates and forms a film, and then coats polyimide precursor resin polyamic acid on it, the coating thickness is 20-30μm, and the polyimide is obtained after thermal imidization Imine copper clad laminate, that is, no adhesive substrate. Test the surface resistance, volume resistivity and peel strength of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com