Method for collaboratively leaching gold in refractory gold ores by virtue of ultrasonic enhancement, chlorination and oxidization

A technology of ultrasonic strengthening and chlorination oxidation, applied in the field of metallurgical industry, can solve the problems of increasing leaching procedures, increasing technological procedures, and difficulty in recovering gold, and achieves the effects of shortening leaching time, shortening technological procedures and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

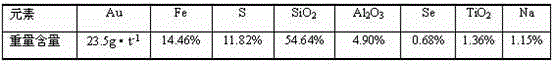

[0030] The present embodiment takes the flotation gold ore of a certain mine as the processing object, and its main components are as shown in Table 1.

[0031] Table 1 Analysis of main components of gold ore

[0032]

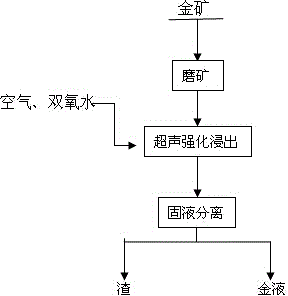

[0033] The method (such as figure 1 shown) specifically includes the following steps:

[0034] (1) Grinding the raw gold ore to below 200 mesh;

[0035] (2) Fully mix the original gold ore powder, sodium hydroxide, sodium hypochlorite and water to obtain the pulp. The liquid-solid ratio of the pulp is 2:1, the mass of sodium oxide is 5% of the mass of the mineral powder, and the concentration of sodium hypochlorite in the pulp 1mol / L;

[0036] (3) Stir the pulp (stirring speed is 300rpm), and feed air at a speed of 100L / h, turn on the ultrasonic wave and control its intensity to 1W / cm 3 , the leaching time is 0.5h, and hydrogen peroxide is added in an amount of 1L / t every half hour.

[0037] The gold ore leached in this embodiment was analyzed and detecte...

Embodiment 2

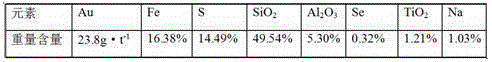

[0039] The present embodiment takes the flotation gold ore of a certain mine as the processing object, and its elemental composition is shown in Table 2.

[0040] Table 2 Analysis of main components of gold ore

[0041]

[0042] (1) Grinding the raw gold ore to below 200 mesh;

[0043] (2) Fully mix the original gold ore powder, sodium hydroxide, sodium hypochlorite and water to obtain the pulp. The liquid-solid ratio of the pulp is 6:1, the mass of sodium oxide is 20% of the mass of the mineral powder, and the concentration of sodium hypochlorite in the pulp is 3mol / L;

[0044] (3) Stir the pulp (stirring speed is 500rpm), and feed air at a speed of 200L / h, turn on the ultrasonic wave and control its intensity to 1W / cm 3 , the leaching time is 4h, and hydrogen peroxide is added in an amount of 3L / t every half hour.

[0045] The gold ore leached in this embodiment was analyzed and tested, and the gold leaching rate was 98.6%, and the weight loss rate was 5.7%.

Embodiment 3

[0047] In this embodiment, the flotation gold ore of a certain mine is used as the processing object, and its elemental composition is shown in Table 3.

[0048] Table 3 Analysis of main components of gold ore

[0049]

[0050] The method (such as figure 1 shown) specifically includes the following steps:

[0051] (1) Grinding the raw gold ore to below 200 mesh;

[0052] (2) Fully mix the original gold ore powder, sodium hydroxide, sodium hypochlorite and water to obtain the pulp, the liquid-solid ratio of the pulp is 3:1, the mass of sodium oxide is 10% of the mass of the mineral powder, and the concentration of sodium hypochlorite in the pulp 2mol / L;

[0053] (3) Stir the pulp (stirring speed is 350rpm), and feed air at a speed of 140L / h, turn on the ultrasonic wave and control its intensity to 2W / cm 3 , the leaching time is 2h, and hydrogen peroxide is added in an amount of 1.5L / t every half hour.

[0054] The gold ore leached in this embodiment was analyzed and tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com