Magnetic composite hydroxyapatite nanoparticles as well as preparation method and application thereof

A technology for compounding hydroxyapatite and hydroxyapatite, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve problems such as poor dispersion, poor operability, and complex synthesis process, and achieve excellent acid resistance The effect of high stability, wide application range and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

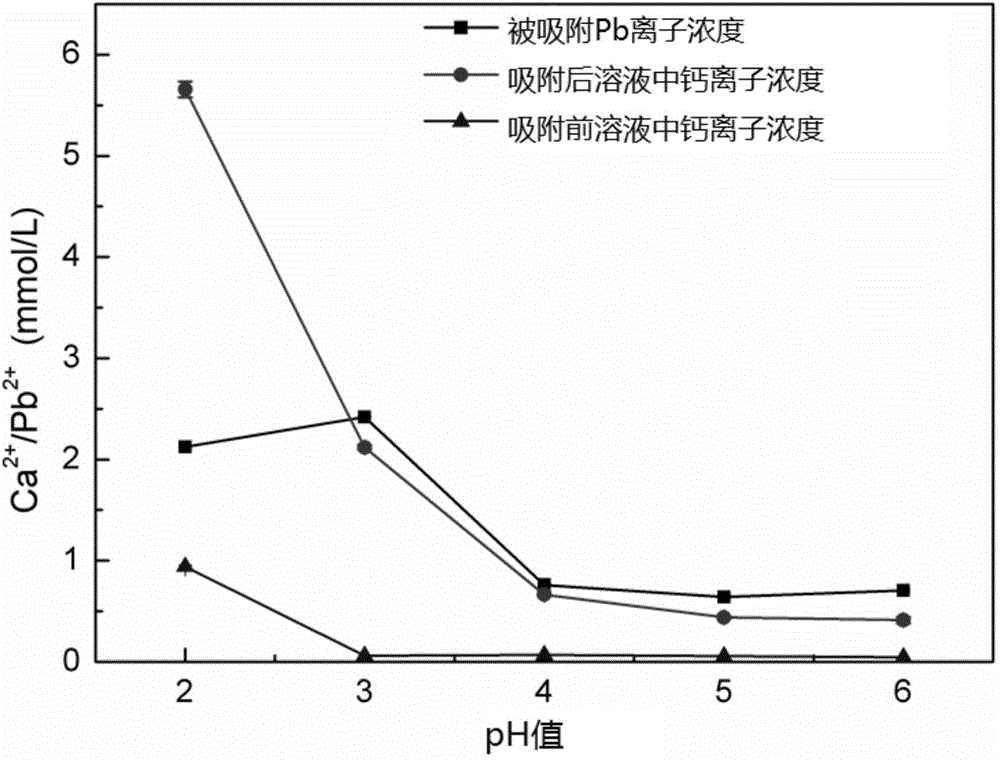

Examples

Embodiment 1

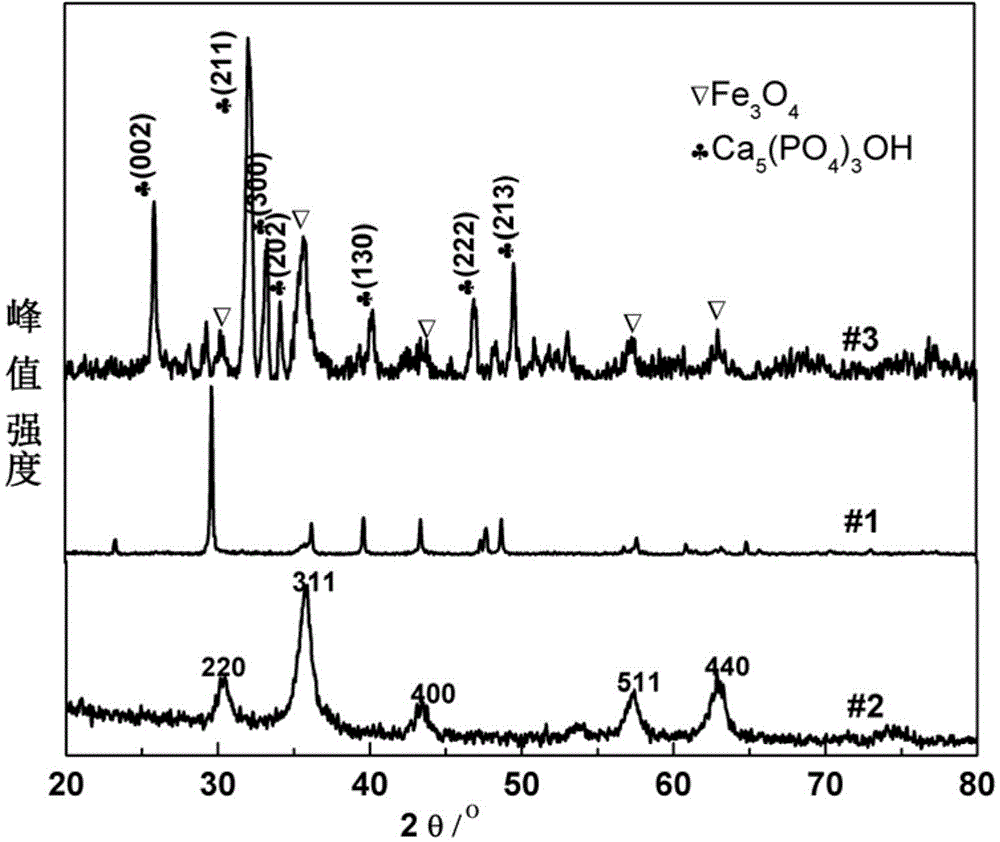

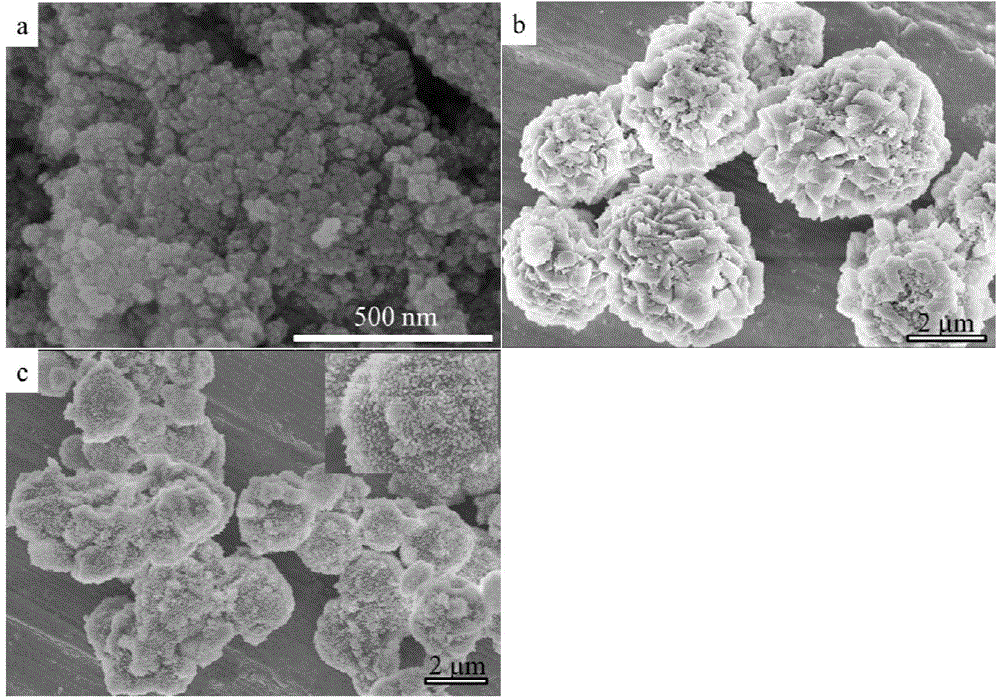

[0028] The preparation method of the magnetic composite hydroxyapatite nanoparticles of embodiment 1 is carried out according to the following steps:

[0029] 1) Under nitrogen protection atmosphere, 0.85g of FeCl 3 ·6H 2 O and 0.30 g FeCl 2 4H 2 0 mixed evenly to form a mixture, then the mixture was dissolved in 200mL deionized water, after mechanical stirring for 30min, ammonia was added dropwise in the solution until the color of the solution turned black, and magnetic separation was carried out after continuing mechanical stirring for 1h to obtain a magnetic substance, The obtained magnetic substance was repeatedly washed with deionized water and absolute ethanol, and then dried at 45°C for 6 hours under vacuum to obtain 0.46 g of black Fe 3 o 4 nanoparticles;

[0030] 2) the prepared 0.46g of Fe 3 o 4 Nanoparticles, 0.89 g of CaCl 2 Mix with 1.15g sodium lauryl sulfate to form a mixture, then dissolve the mixture in 120mL deionized water, stir mechanically for 30m...

Embodiment 2

[0033] The preparation method of the magnetic composite hydroxyapatite nanoparticles of embodiment 2 is carried out according to the following steps:

[0034] 1) Under nitrogen protection atmosphere, 1.7g of FeCl 3 ·6H 2 O and 0.60 g FeCl 2 4H 2 0 mixed evenly to form a mixture, then the mixture was dissolved in 200mL deionized water, after mechanical stirring for 30min, ammonia was added dropwise in the solution until the color of the solution turned black, and magnetic separation was carried out after continuing mechanical stirring for 3h to obtain a magnetic substance, The obtained magnetic substance was repeatedly washed with deionized water and absolute ethanol, and then dried at 50°C under vacuum for 5 hours to obtain 0.92 g of black Fe 3 o 4 nanoparticles;

[0035] 2) the prepared 0.92g of Fe 3 o 4 Nanoparticles, 0.89 g of CaCl 2 Mix with 1.15g sodium lauryl sulfate to form a mixture, then dissolve the mixture in 120mL deionized water, stir mechanically for 30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com