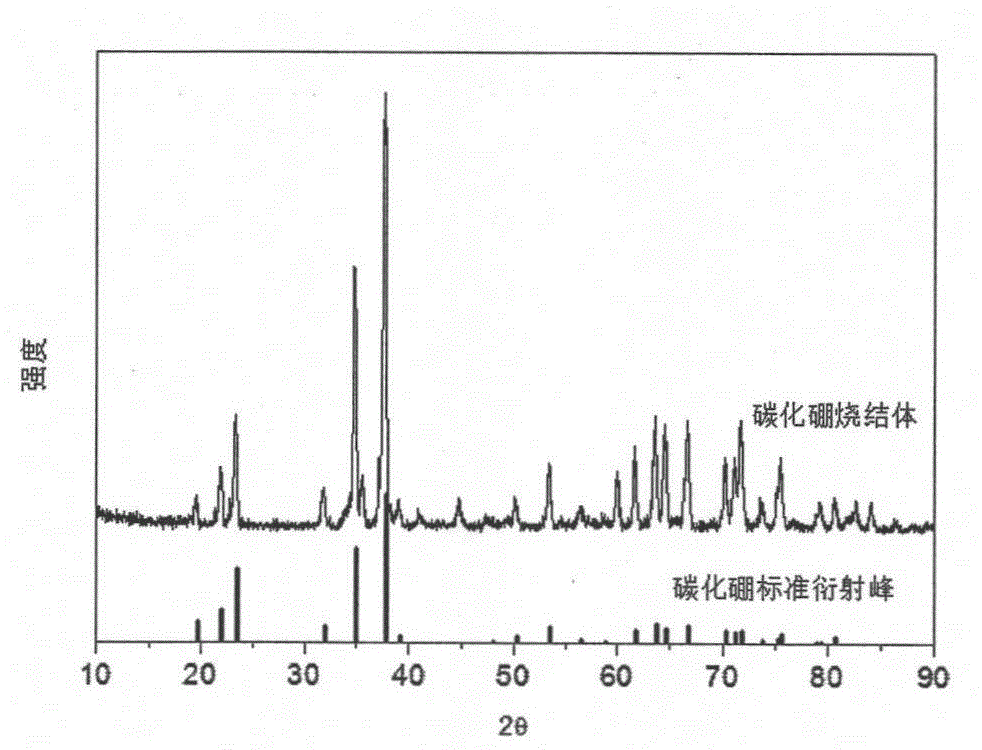

Method for preparing boron carbide ceramic material through low-temperature fast sintering

A rapid sintering technology for boron carbide ceramics, applied in the field of ceramic materials, can solve the problems of uneven microstructure of ceramics, easy agglomeration of ultra-fine powder, and influence of ceramic performance, and achieve good application prospects, good sintering activity, and fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

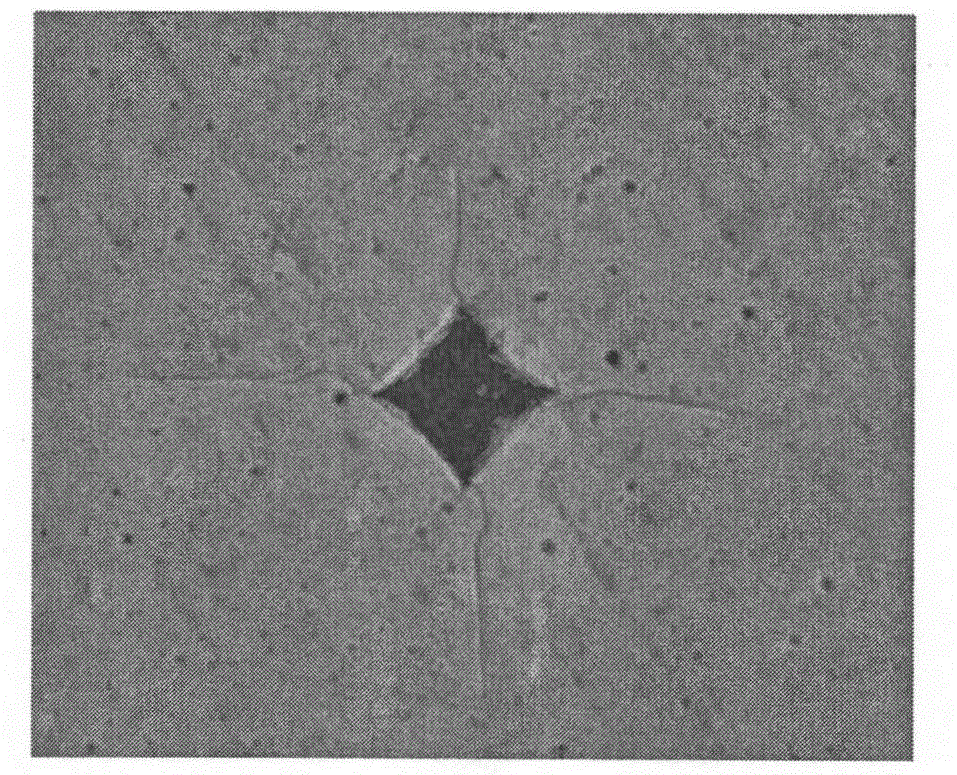

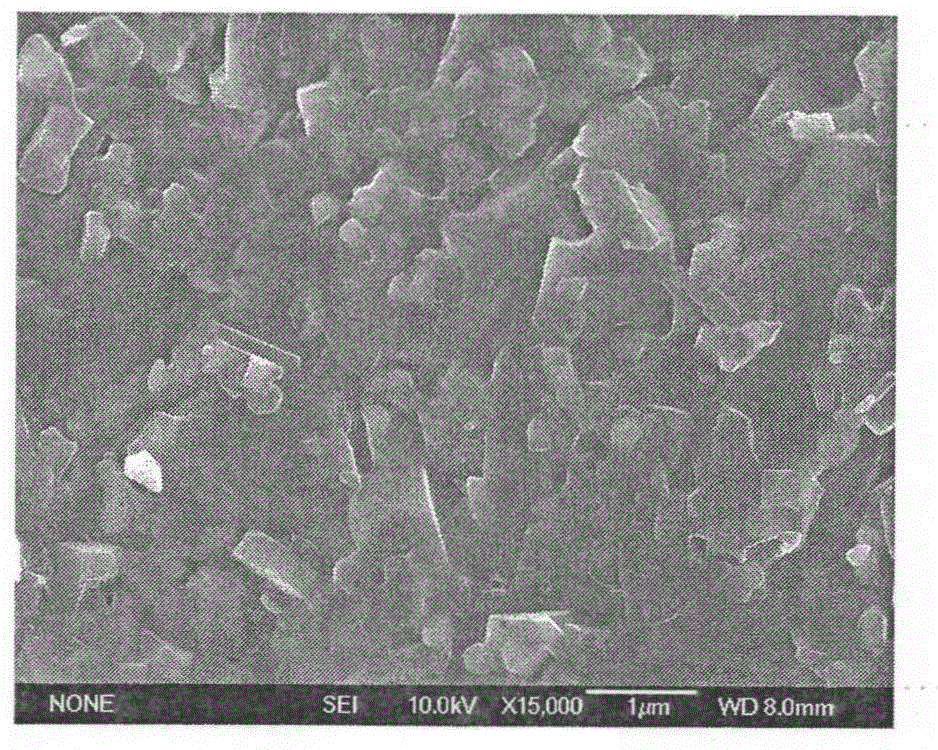

Embodiment 1

[0019] A method for preparing a boron carbide ceramic material by rapid sintering at low temperature, the specific steps are:

[0020] (1) Using the hard template mesoporous silica SBA-15 as the structure-directing agent, the porous boron carbide powder was synthesized by nano-casting method: 2.73g of mesoporous silica SBA-15 and 2.5g of the precursor didecaboryl - Disperse bisdecaboranyl-hexane (bisdecaboranyl-hexane) in 200ml of absolute ethanol and stir evenly, and the solvent is rotated to evaporate the solvent. Put the body into an alumina crucible, heat-treat it under an argon atmosphere, raise the temperature to 300°C at a heating rate of 1°C / min, keep it for 7 hours, then raise it to 700°C at a rate of 0.5°C / min, keep it for 1 hour, and then heat it at 2°C / min The temperature was raised to 1000°C for 2 hours, and the precursor was converted into boron carbide (B 4 C), soak the heat-treated powder with an ethanol solution containing 40% hydrofluoric acid, repeat severa...

Embodiment 2

[0024] A method for preparing a boron carbide ceramic material by rapid sintering at low temperature, the specific steps are:

[0025] (1) Using the hard template mesoporous silica KIT-6 as the structure-directing agent, the porous boron carbide powder was synthesized by nano-casting method: 1.95g of mesoporous silica KIT-6 and 2.5g of the precursor didecaboryl - Disperse bisdecaboranyl-hexane (bisdecaboranyl-hexane) into 200ml of absolute ethanol and stir evenly, and volatilize the solvent in a Petri dish covered with PE film to introduce the precursor bisdecaboranyl-hexane (bisdecaboranyl-hexane) into the hard disk In the channel of the template, put the obtained powder into an alumina crucible, heat treatment in an argon atmosphere, raise the temperature to 300°C at a heating rate of 1°C / min, keep it for 7 hours, and then raise the temperature to 700°C at a rate of 0.5°C / min , keep it warm for 1h, then raise the temperature at 2°C / min to 1000°C for 2h, and convert the precu...

Embodiment 3

[0029] A method for preparing a boron carbide ceramic material by rapid sintering at low temperature, the specific steps are:

[0030] (1) Using the hard template mesoporous silica MCM-41 as the structure-directing agent, the porous boron carbide powder was synthesized by nano-casting method: 2.3g of mesoporous silica MCM-41 and 2.5g of the precursor didecaboryl - Disperse bisdecaboranyl-hexane (bisdecaboranyl-hexane) in 200ml of absolute ethanol and stir evenly, and the solvent is rotated to evaporate the solvent. Put the body into an alumina crucible, heat treatment under nitrogen atmosphere, raise the temperature to 300°C at a heating rate of 1°C / min, keep it for 7h, then raise the temperature to 700°C at 0.5°C / min, keep it for 1h, and then heat it at 0.5°C / min Raise the temperature to 1000°C and keep it for 1h to convert the precursor into boron carbide (B 4 C), soak the heat-treated powder with an ethanol solution containing 40% hydrofluoric acid, repeat several times to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com