Preparation method for polylactic acid fiber three-dimensional bionic porous ordered scaffold

A polylactic acid fiber, polylactic acid technology, which is applied in the fields of medical science, surgery, prosthesis, etc., can solve problems such as poor thermal stability, and achieve the effect of simple method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

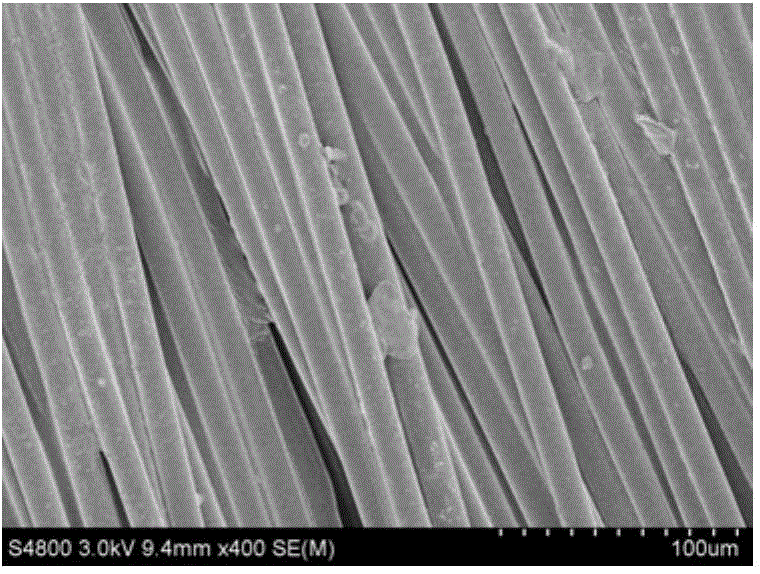

[0052] PLA slices with a molecular weight of 170,000 were prepared by melt spinning method into PLA melt-spun fibers with an average diameter of 12.41 μm, and the aggregates arranged in parallel were wound with a skein length measuring instrument, the rotation speed was 300r / min, and the circumference of the yarn frame It is 1000mm and the width is 3.5cm. 800 PLA fibers arranged in parallel were wound with an initial tension of 100cN. Fully submerge the brush in the 15% solid content polyurethane adhesive for about 2 seconds, take out the brush and lightly brush on the PLA fiber surface once, then completely immerse the brush in the 15% solid content polyurethane adhesive for about 2 seconds, Take out the brush and brush lightly on the surface of the PLA fiber once, so that the ordered fiber bundles of PLA are bonded into a whole. Curing at 40°C for 1 hour without any tension during the curing process. Naturally cooled to room temperature, the three-dimensional porous orde...

Embodiment 2

[0055] Adopt the same method and condition as embodiment 1, just change the number of PLA fibers to be 1300. The surface and cross-sectional morphology of the PLA melt-spun fiber ordered scaffold prepared in this embodiment are as follows: image 3 and 4 shown.

[0056] The prepared three-dimensional porous ordered scaffold has an average thickness of 0.0988cm and a weight of 0.05466g / cm 2 , the degree of order is 104.78°, the pore diameter is 5.90 μm, the porosity is 53.33%, and the connectivity between pores is good. Since water droplets directly enter the internal pores from the surface of the scaffold, it can be known from the contact angle test that the scaffold is hydrophilic. The water absorption rate of the scaffold was 116.22% in 1h, and 141.42% in 6h. The adsorption capacity of the scaffold to 1mg / mL gelatin solution in 10min is 0.66g / cm 3 , the adsorption capacity at 60min is 0.63g / cm 3 . The tensile stress and strain of the scaffold along the fiber alignment...

Embodiment 3

[0058] The PLA slices with a molecular weight of 200,000 were prepared into PLA melt-spun fibers with an average diameter of 12.41 μm, and a parallel assembly was wound with a skein length measuring instrument at a speed of 1 r / min. The circumference of the yarn frame was 1000 mm, and the width was 3.5cm. 1000 PLA fibers arranged in parallel were wound with an initial tension of 100cN. Submerge the brush completely in 5% solid content cyanoacrylate adhesive for about 2 seconds, take out the brush and brush lightly on the PLA fiber surface once, then completely immerse the brush in 5% solid content polyurethane adhesive After about 2 seconds, take out the brush and brush lightly on the surface of the PLA fiber once, so that the ordered fiber bundles of PLA can be bonded into a whole. At 100°C, the curing time is 1.5h, and no tension is added during the curing process. Naturally cooled to room temperature, the three-dimensional porous ordered scaffold of PLA melt-spun fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com