Environment-friendly high-dispersion permanent magnet wire cutting fluid

An environmentally friendly and highly dispersible technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of rusted and scrapped workpieces, easy oxidation reactions, poor anti-rust and anti-corrosion performance, etc., to achieve long cycle life and safety The effect of high hygienic quality and excellent antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

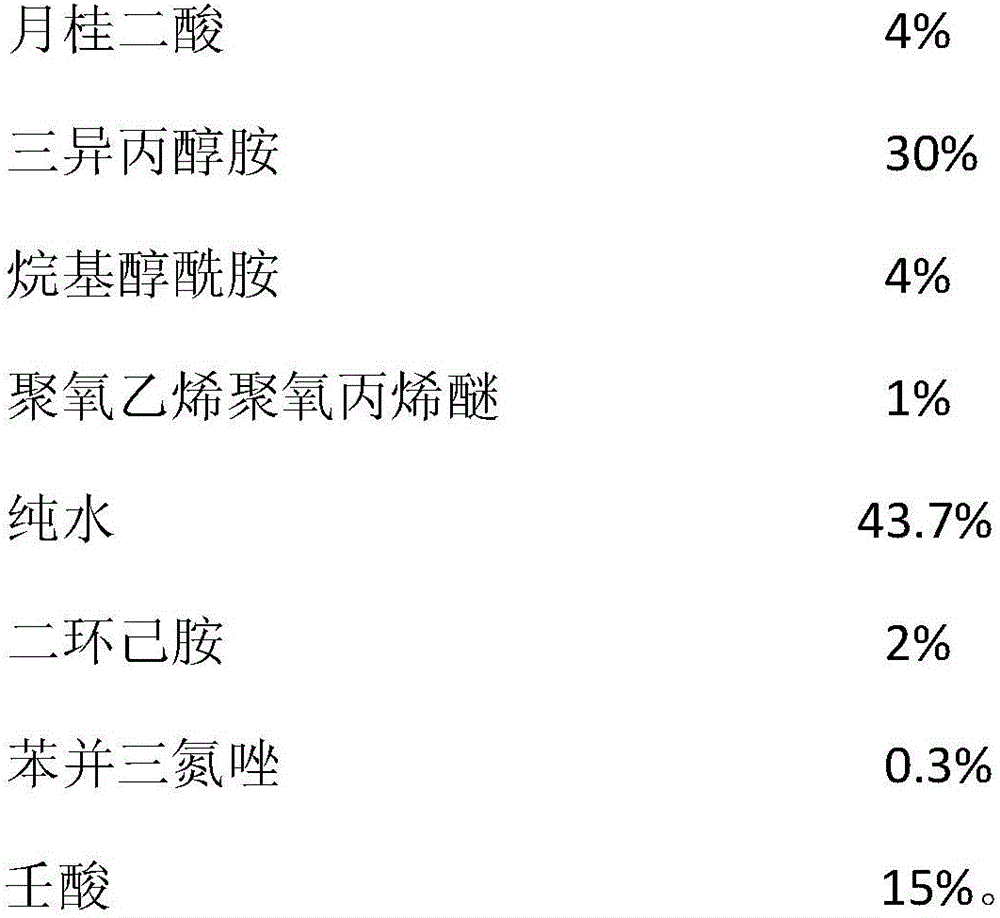

[0023] An environment-friendly high-dispersion permanent magnet wire-cutting fluid is a product obtained by mixing and stirring the following weight components:

[0024] Lauric acid 4%

[0025] Triisopropanolamine 30%

[0026] Alkanolamide 4%

[0027] Polyoxyethylene polyoxypropylene ether 1%

[0028] Pure water 43.7%

[0029] Dicyclohexylamine 2%

[0030] Benzotriazole 0.3%

[0031] Nonanoic Acid 15%.

[0032] In this example, macromolecular carboxylic acid lauric acid is used as a high-efficiency rust and corrosion inhibitor, which has excellent rust resistance (3.3% diluted iron filings rust prevention ≥ 120 hours) and corrosion resistance (brown iron ion content ≤10ppm), the working fluid can be used for a long time without browning, and the cycle life is long (>100 days), which not only reduces the cost of changing the fluid, but also ensures the quality of the processed parts.

Embodiment 2

[0034] An environment-friendly high-dispersion permanent magnet wire-cutting fluid consists of the following components by weight percentage:

[0035] Polymer carboxylic acid 10-30% (eg 10%, 20%, 30%)

[0036] Organic amine 20-40% (eg 20%, 30%, 40%)

[0037] New surfactant 1~20% (eg 1%, 10%, 20%)

[0038] Pure water 35-65% (eg 35%, 50%, 65%)

[0039] Preservatives or fungicides 0-5% (eg 1%, 2%, 5%).

[0040] The polymer carboxylic acid is a long-chain carboxylic acid such as caprylic acid, n-nonanoic acid, sebacic acid, adipic acid, azelaic acid, lauric acid, C8-C18 fatty acid, oleic acid, linoleic acid, triazines, etc. One or more of the carboxylic acid compounds.

[0041] The organic amine is monoethanolamine, diethanolamine, triethanolamine, monoisopropanolamine, diisopropanolamine, triisopropanolamine, morpholine, dicyclohexylamine, N-methylmorpholine, 2-amino -One or more of 2-methyl-1-propanol and diethylaminoethanol.

[0042] The surfactant is fatty alcohol polyox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com