Sol-gel preparation method for copper yttrium titanate giant dielectric ceramic material

A sol-gel method and a technology for ceramic materials, which are applied in the field of preparation of giant dielectric ceramic materials, can solve the problems of difficulty in wide application and high dielectric loss, and achieve the effects of high yield, reduced dielectric loss and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

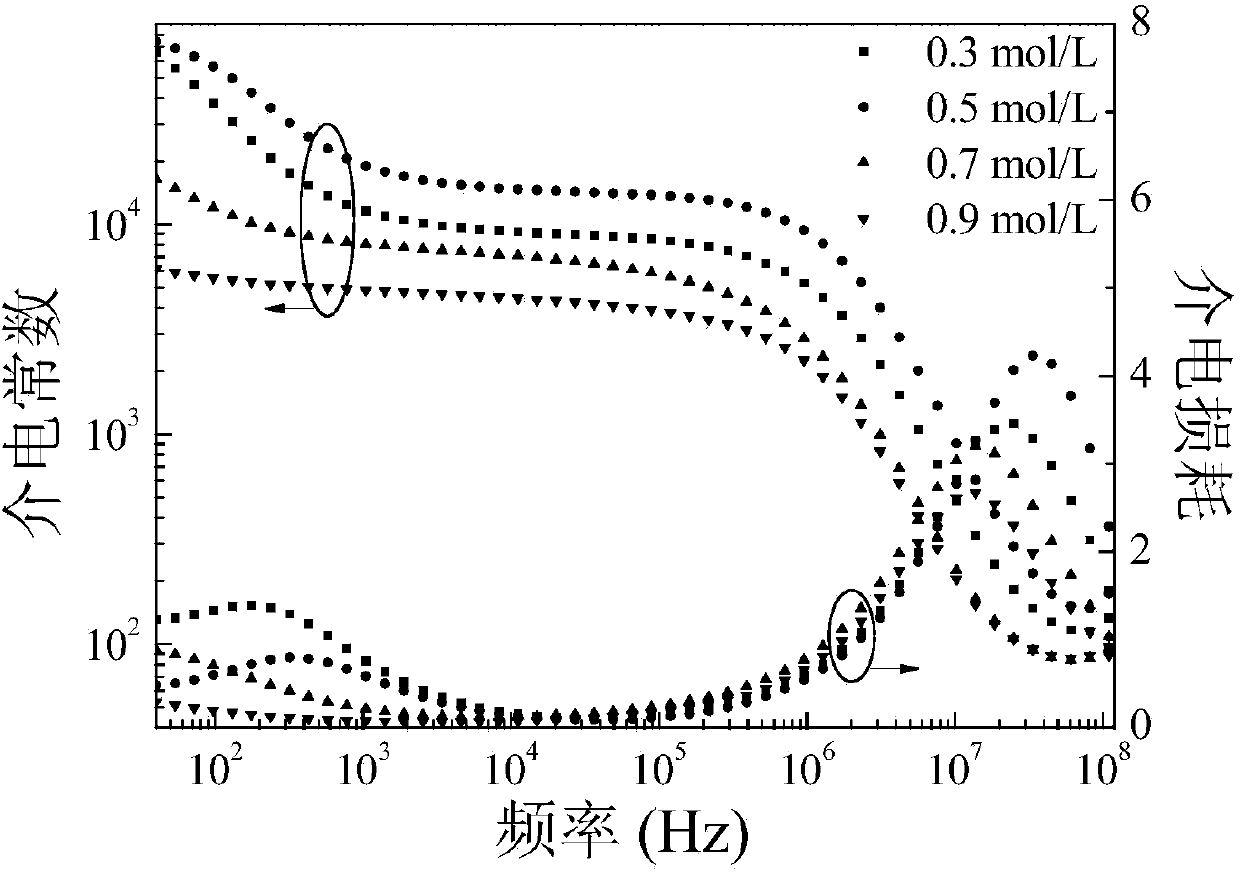

Embodiment 1

[0034] 1. Ingredients

[0035] According to formula Y 2 / 3 Cu 3 Ti 4 o 12 The stoichiometry of raw material Y(NO 3 ) 3 ·6H 2 O2.5537g, Cu(NO 3 ) 2 ·3H 2 O7.3212g, Ti(C 4 h 9 O) 4 13.90mL, Y(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O was dissolved in 9mL of ethanol and deionized water volume ratio of 1:9 mixed solution, recorded as solution 1; Ti(C 4 h 9 O) 4 Dissolve it in 56mL of a mixed solution with a volume ratio of acetic acid and ethanol of 1:6, and record it as solution 2; slowly pour solution 1 into solution 2 with a stirring speed of 200 rpm, and the content of butyl titanate in the resulting mixed solution The concentration is 0.5mol / L, the volume fraction of acetic acid is 10%, and the volume fraction of deionized water is 11%. React in a water bath at 35°C for 6 hours to obtain a gel, which is aged for 8 hours and then placed in an oven Dry at 120°C, grind, and pass through an 80-mesh sieve to obtain xerogel powder.

[0036] 2. Pre-burning

[0037] P...

Embodiment 2

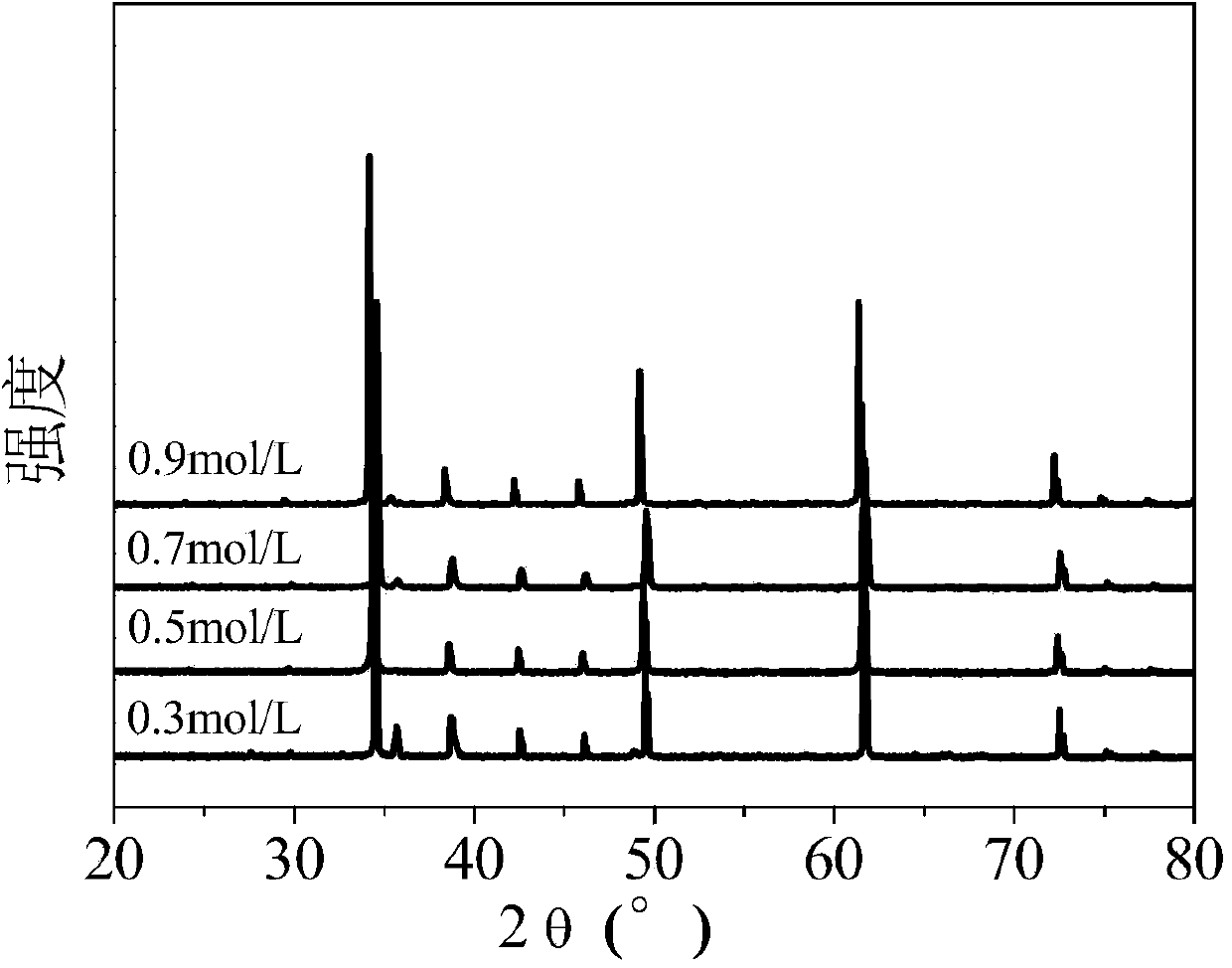

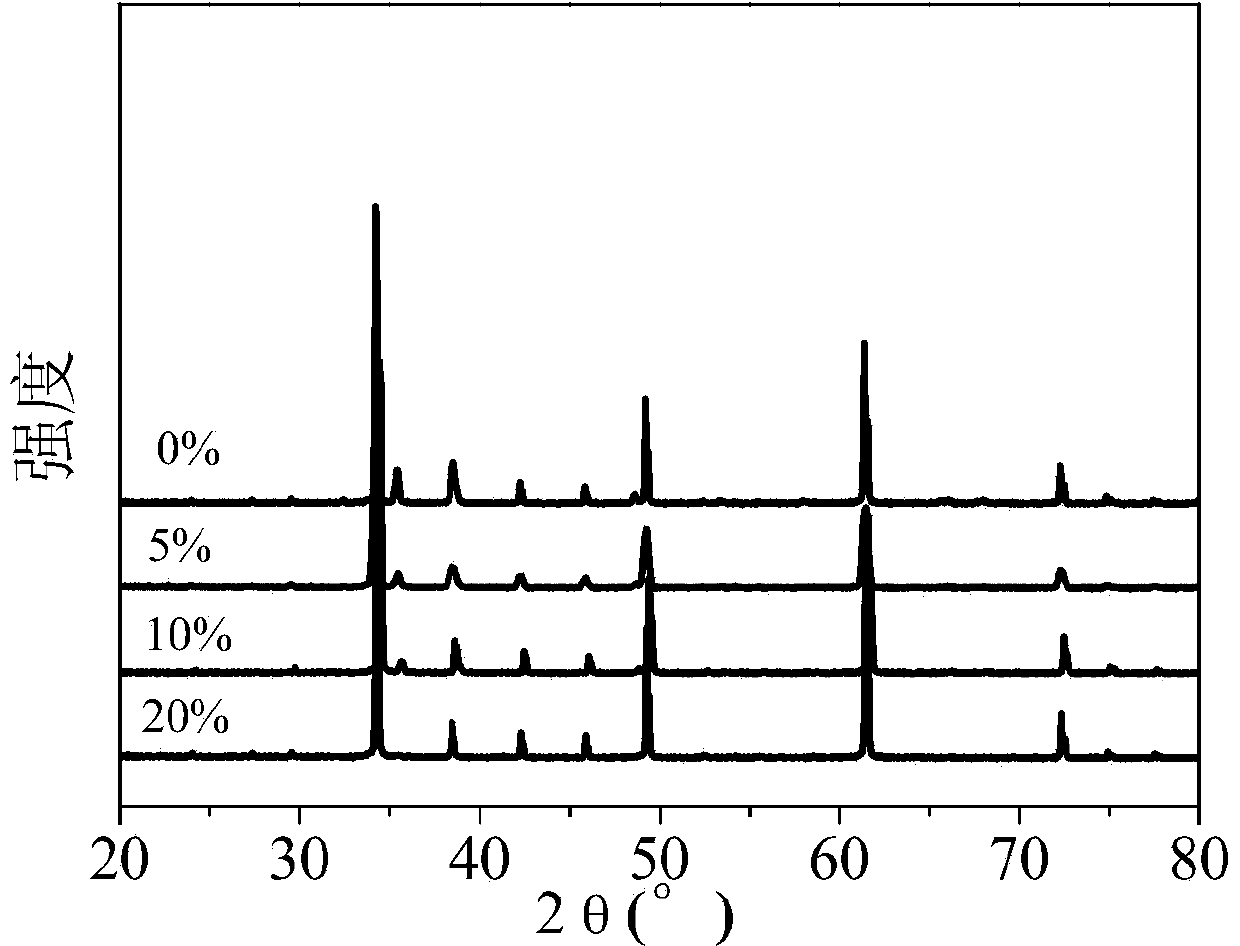

[0049] In the batching step 1 of embodiment 1, according to general formula Y 2 / 3 Cu 3 Ti 4 o 12 The stoichiometry of raw material Y(NO 3 ) 3 ·6H 2 O2.5537g, Cu(NO 3 ) 2 ·3H 2 O7.3212g, Ti(C 4 h 9 O) 4 13.90mL, Y(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O dissolved in 20mL deionized water, recorded as solution 1; Ti(C 4 h 9 O) 4 Dissolve in 99mL of a mixed solution with a volume ratio of acetic acid and ethanol of 1:4, and record it as solution 2; slowly pour solution 1 into solution 2 with a stirring speed of 200 rpm, and the butyl titanate in the resulting mixed solution The concentration is 0.3mol / L, the volume fraction of acetic acid is 15%, and the volume fraction of deionized water is 15%. React in a water bath at 40°C for 4 hours to obtain a gel. The obtained gel is aged for 8 hours and then placed in an oven Dry at 120°C, grind, and pass through an 80-mesh sieve to obtain xerogel powder. The other steps are the same as in Example 1, and a copper yttrium...

Embodiment 3

[0051] In the batching step 1 of embodiment 1, according to general formula Y 2 / 3 Cu 3 Ti 4 o 12 The stoichiometry of raw material Y(NO 3 ) 3 ·6H 2 O2.5537g, Cu(NO 3 ) 2 ·3H 2 O7.3212g, Ti(C 4 h 9 O) 4 13.90mL, Y(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O was dissolved in 10mL of deionized water and ethanol in a mixed solution with a volume ratio of 1:6, which was recorded as solution 1; Ti(C 4 h 9 O) 4 Dissolve in 20.5mL of a mixed solution of acetic acid and ethanol with a volume ratio of 1:8, and record it as solution 2; slowly pour solution 1 into solution 2 with a stirring speed of 200 rpm, and the butyl titanate in the resulting mixed solution The concentration is 0.9mol / L, the volume fraction of acetic acid is 5%, the volume fraction of deionized water is 3%, and react at room temperature for 8 hours to obtain a gel. Dry, grind, and pass through an 80-mesh sieve to obtain xerogel powder. The other steps are the same as in Example 1, and a copper yttrium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com