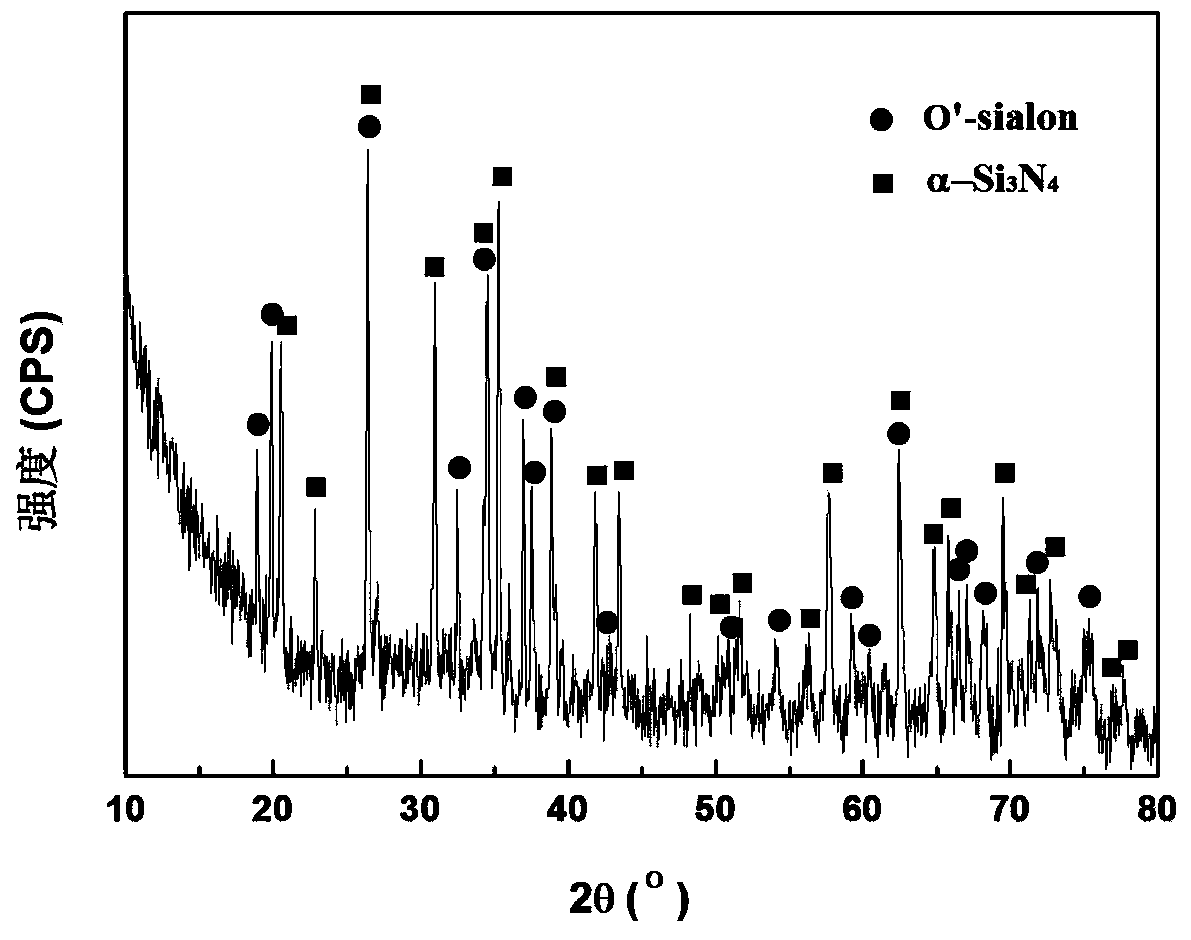

Method for preparing compact O'-sialon/alpha-Si3N4 composite ceramic coating on surface of porous nitride ceramic base body

A nitride ceramic, -si3n4 technology is applied in the field of preparation of ceramic coatings, which can solve the problems of delamination and coating cracking, and achieve the effects of high efficiency, shortened production cycle, and improved erosion resistance and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

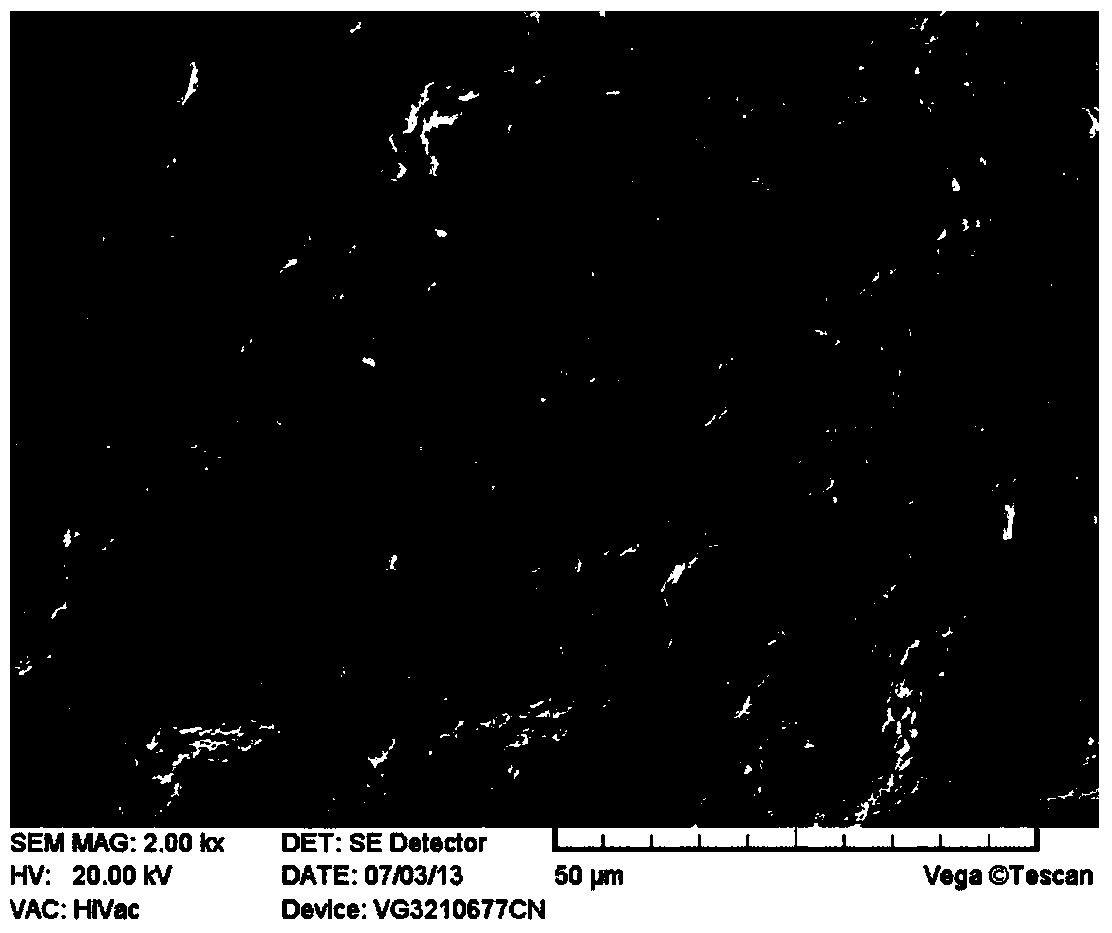

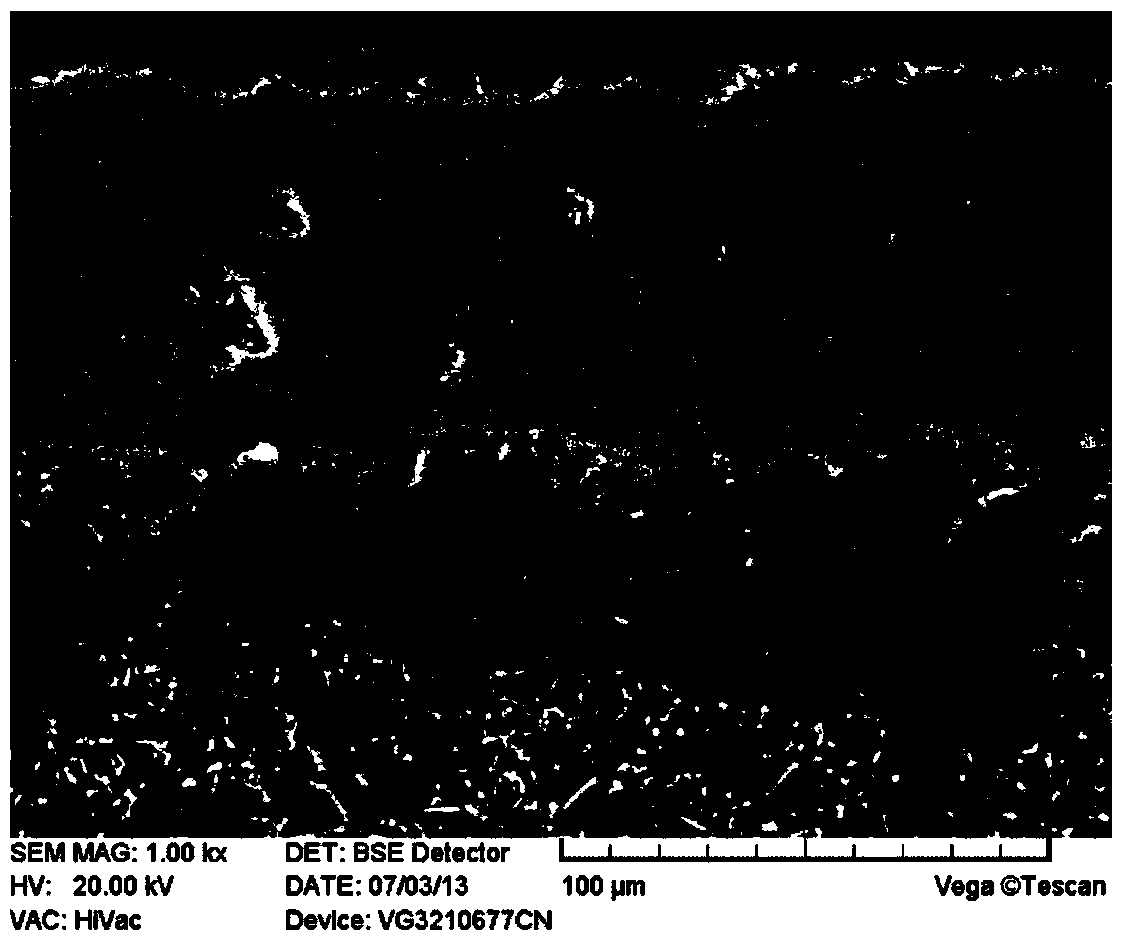

[0030] This example is to prepare dense O'-sialon / α-Si on the surface of porous silicon nitride ceramic substrate with high porosity 3 N 4 Multiphase ceramic coating, comprising the following steps:

[0031] Step 1, substrate treatment: select a porous silicon nitride ceramic substrate with a porosity of 62%, use 400 mesh, 800 mesh, and 1000 mesh sandpaper to grind successively until the surface of the substrate is smooth and flat, and then put the porous silicon nitride ceramic substrate after grinding. Ultrasonic cleaning in distilled water for 25 minutes, after cleaning twice, put the substrate into an oven and dry at 70°C for 8 hours;

[0032] Step 2, preparation of yttrium aluminum silicon ceramic powder: Y 2 o 3 , SiO 2 、Al 2 o 3 The mixture is mixed with absolute ethanol, and its solid content is 20%, wherein Y 2 o 3 , SiO 2 、Al 2 o 3 In the oxide raw material powder, the mass percentage is Y 2 o 3 :SiO2 2 :Al 2 o 3 =34.04:45.32:20.64, with silicon nitri...

Embodiment 2

[0039] This example is to prepare dense O'-sialon / α-Si on the surface of porous silicon nitride ceramic substrate with low porosity 3 N 4 Multiphase ceramic coating, comprising the following steps:

[0040] Step 1, substrate treatment: select a porous silicon nitride ceramic substrate with a porosity of 34%, use 400 mesh, 800 mesh, and 1000 mesh sandpaper to grind successively until the surface of the substrate is smooth and flat, and then put the porous silicon nitride ceramic substrate after grinding. Ultrasonic cleaning in distilled water for 15 minutes, after cleaning twice, put the substrate into an oven, and dry at 80°C for 15 hours;

[0041] Step 2, preparation of yttrium aluminum silicon ceramic powder: Y 2 o 3 , SiO 2 、Al 2 o 3 The mixture is mixed with absolute ethanol, and its solid content is 20%, wherein Y 2 o 3 , SiO 2 、Al 2 o 3 In the oxide raw material powder, the mass percentage is Y 2 o 3 :SiO2 2 :Al 2 o 3 =34.04:45.32:20.64, with silicon nitr...

Embodiment 3

[0048] This example is to prepare dense O'-sialon / α-Si on the surface of porous sialon ceramic substrate 3 N 4 Multiphase ceramic coating, comprising the following steps:

[0049] Step 1, substrate treatment: select a porous sialon ceramic substrate with a porosity of 45%, use 400 mesh, 800 mesh, and 1000 mesh sandpaper to grind successively until the surface of the substrate is smooth and flat, and then put the ground porous sialon ceramic substrate into distilled water for ultrasonic Wash for 20 minutes, after washing twice, put the substrate into the oven, and dry at 80°C for 12 hours;

[0050] Step 2, preparation of yttrium aluminum silicon ceramic powder: Y 2 o 3 , SiO 2 、Al 2 o 3 The mixture is mixed with absolute ethanol, and its solid content is 20%, wherein Y 2 o 3 , SiO 2 、Al 2 o 3 In the oxide raw material powder, the mass percentage is Y 2 o 3 :SiO2 2 :Al 2 o 3 =34.04:45.32:20.64, with silicon nitride balls as grinding balls, silicon nitride balls a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com