Alkali soluble resin and photosensitive resin composition containing the same

A technology of alkali-soluble resins and photosensitive resins, which is applied in the field of alkali-soluble resins and photosensitive resin compositions containing the alkali-soluble resins, and can solve problems such as developing speed, poor sensitivity, poor adhesion, insufficient sensitivity, and slow developing speed , to achieve the effects of excellent sensitivity and adhesion, excellent contrast and light transmittance, and not easy to pattern short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

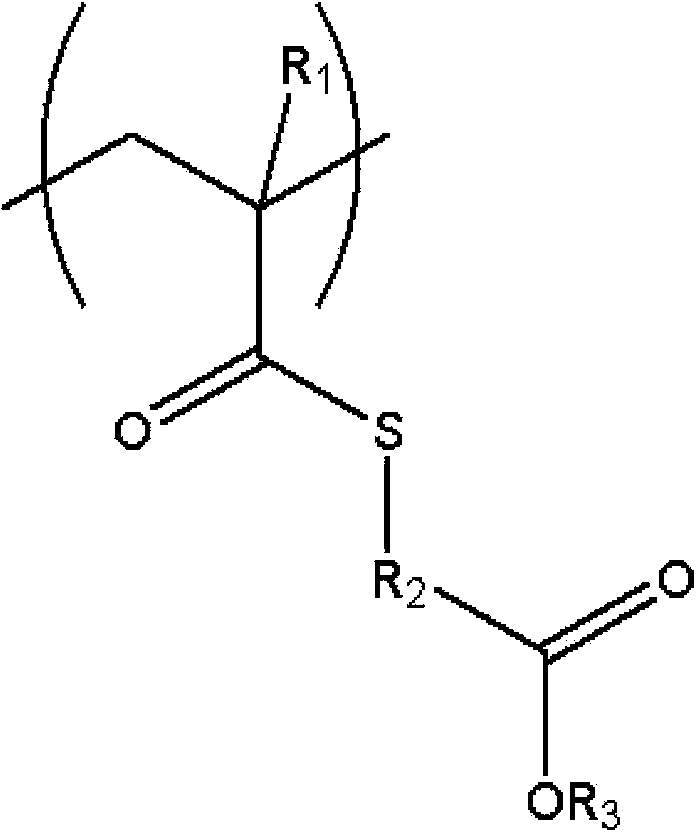

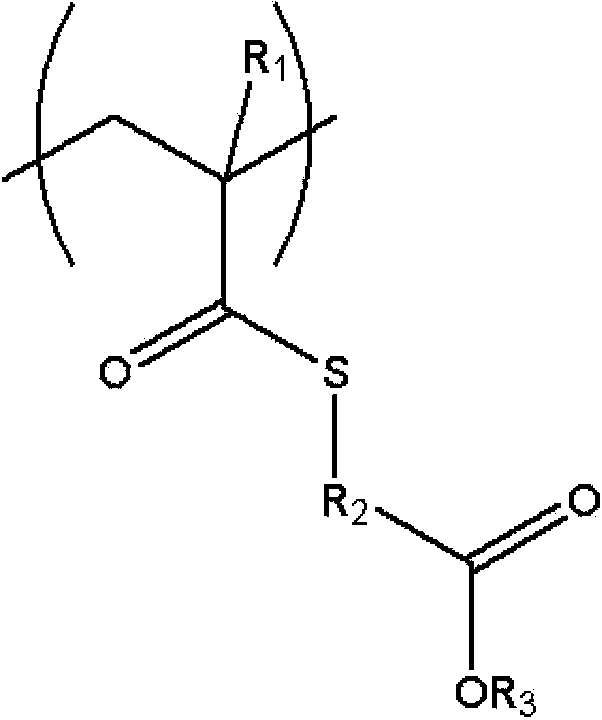

[0136] Production Example 1: Synthesis of Compound of Chemical Formula 3

[0137] 51.1 g of thioglycolic acid, 39.5 g of triethylamine, and 240 g of tetrahydrofuran were put into a 4-necked round bottom flask equipped with a cooler and a stirrer, and the internal temperature of the reactor was cooled to -10°C while stirring.

[0138] Next, after adding 51.1 g of methacryloyl chloride dropwise for 30 minutes, the reaction temperature was raised to room temperature, and the reaction was continued for 5 hours.

[0139] After completion of the reaction, 90 g of a saturated aqueous sodium bicarbonate solution was added to the reaction liquid, and then 140 g of ethyl acetate was added for extraction. It was washed with 124 g of saturated brine, dried over anhydrous magnesium sulfate, and filtered.

[0140] Thereafter, the organic solvent was removed with a rotary evaporator to obtain 49.5 g of a colorless transparent oily substance, which was subjected to column purification using ...

manufacture example 2

[0144] Production Example 2: Production of Pigment Dispersion Liquid

[0145] 12.0 grams of pigment C.I pigment blue 15:6, 4.0 grams of pigment dispersant DISPERBYK-2001 (manufactured by BYK), 44 grams of solvent propylene glycol methyl ether acetate and 40 grams of propylene glycol methyl ether were mixed for 12 hours by a ball mill, and the It is dispersed to produce a pigment dispersion.

Embodiment 1

[0146] Embodiment 1: the manufacture of alkali-soluble resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com