Marine heavy anticorrosive coating material and preparation method thereof

A heavy-duty anti-corrosion and coating technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of weather resistance, poor corrosion resistance, surface dryness, long hard-drying time, cumbersome preparation process, etc., and achieve anti-corrosion Good sag performance, good film-forming property and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of marine heavy-duty anticorrosion coating, its difference with prior art is: described preparation method comprises the following steps: a, preparation A component, with resin, surfactant and 60% of solvent total amount The solvent was dispersed at a high speed for 20 minutes at a speed of 2000r / min; then the thixotropic agent and 10% of the total solvent were added, and stirred again at the same speed for 10 minutes; then the pigment and filler were added at a speed of 2000r / min Disperse at high speed for 20 minutes under the condition of high speed; finally add defoamer, thickener, Al slurry and the remaining 30% solvent, mix evenly under the condition of 1000r / min, separate and pack for use, and obtain component A;

[0031] b. To prepare component B, mix the curing agent and solvent evenly according to a certain ratio, and pack it separately for use to obtain component B;

[0032] c. When using, mix components A and B at a volume ratio o...

Embodiment 1

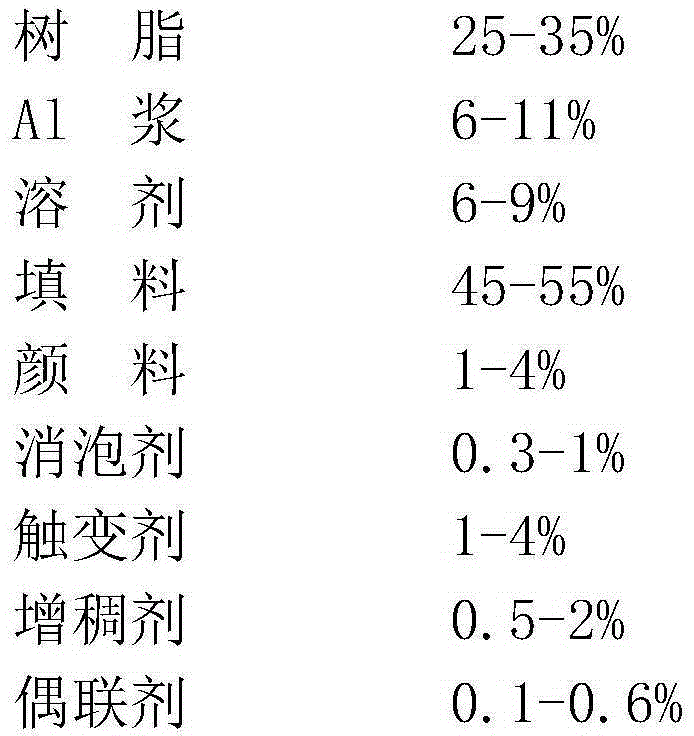

[0040] A marine heavy-duty anti-corrosion coating, which consists of two components A and B, wherein:

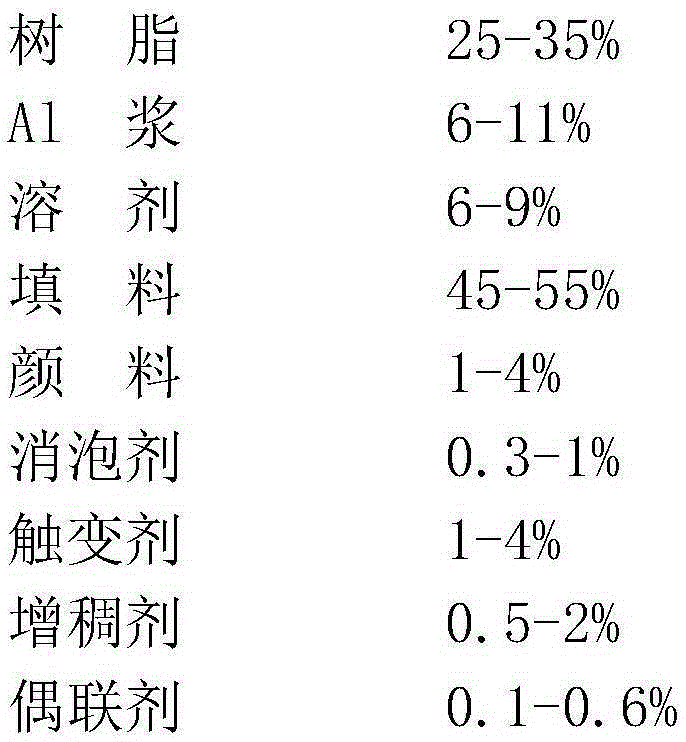

[0041] The composition and mass percentage of component A are:

[0042]

[0043] The composition and mass percentage of component B are:

[0044]

[0045] The specific preparation method is:

[0046] First, disperse the resin, surfactant and 60% of the total solvent in component A at a high speed for 20 minutes at a speed of 2000r / min; then add the thixotropic agent and 10% of the total solvent, Stir again at the same rate for 10 minutes; then add pigments and fillers and disperse at a high speed for 20 minutes at a speed of 2000r / min; finally add defoamer, thickener, Al slurry and the remaining 30% solvent, and mix at 1000r / min Min under the condition of mixing evenly, sub-package for use, that is the A component;

[0047] Mix the curing agent and solvent in component B evenly according to a certain ratio; divide and pack for use, and then get component B;

[0048...

Embodiment 2

[0051] A marine heavy-duty anti-corrosion coating, which consists of two components A and B, wherein:

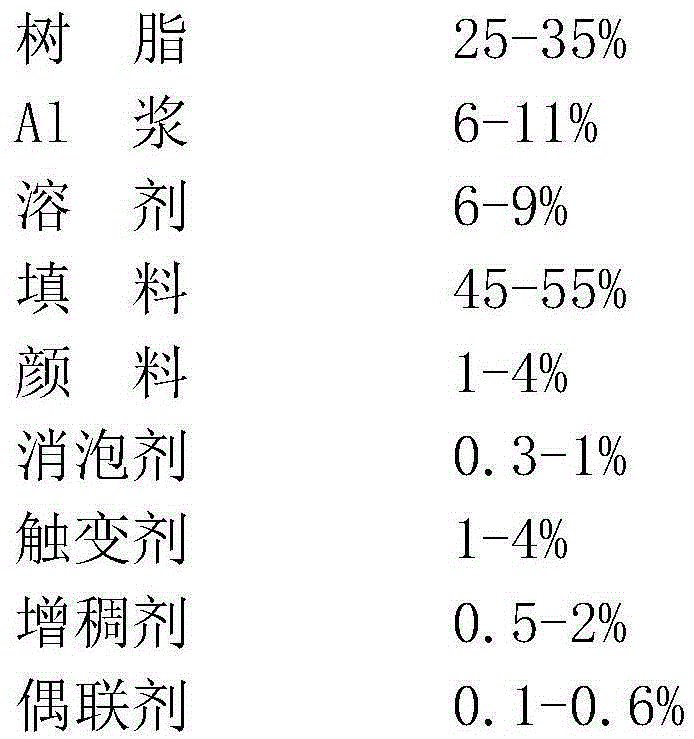

[0052] The composition and mass percentage of component A are:

[0053]

[0054] The composition and mass percentage of component B are:

[0055]

[0056] The specific preparation method is:

[0057] First, disperse the resin, surfactant and 60% of the total solvent in component A at a high speed for 20 minutes at a speed of 2000r / min; then add the thixotropic agent and 10% of the total solvent, Stir again at the same rate for 10 minutes; then add pigments and fillers and disperse at a high speed for 20 minutes at a speed of 2000r / min; finally add defoamer, thickener, Al slurry and the remaining 30% solvent, and mix at 1000r / min Min under the condition of mixing evenly, sub-package for use, that is the A component;

[0058] Mix the curing agent and solvent in component B evenly according to a certain ratio; divide and pack for use, and then get component B;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com