Preparation method of degradable environmental sensitive polymer nano hydrogel and application

A nano-hydrogel and environmental responsive technology, which is applied in the direction of medical preparations and pharmaceutical formulas of non-active ingredients, can solve the problems of complex synthesis methods and many steps, and achieve simple preparation methods, good dispersibility, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

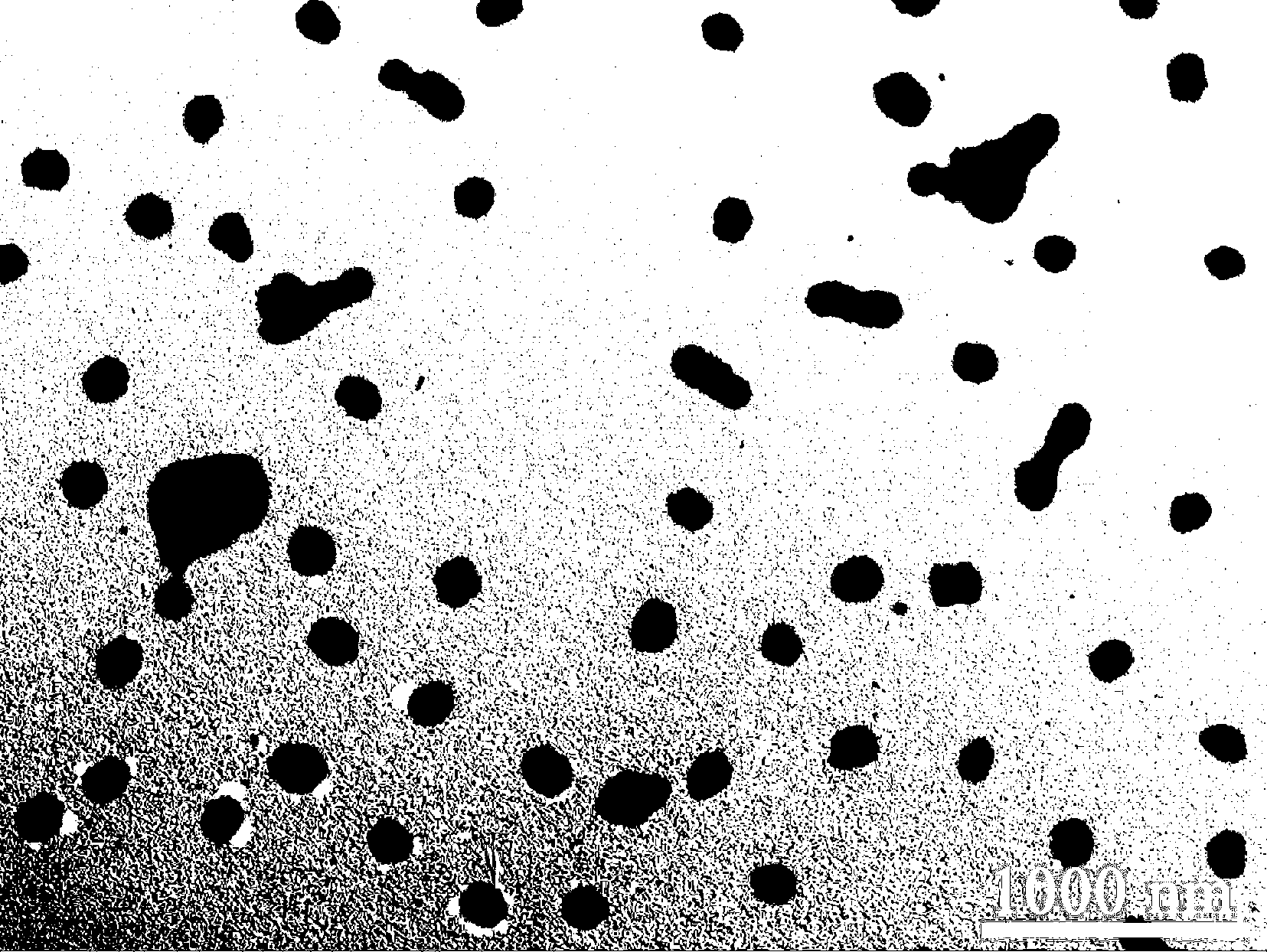

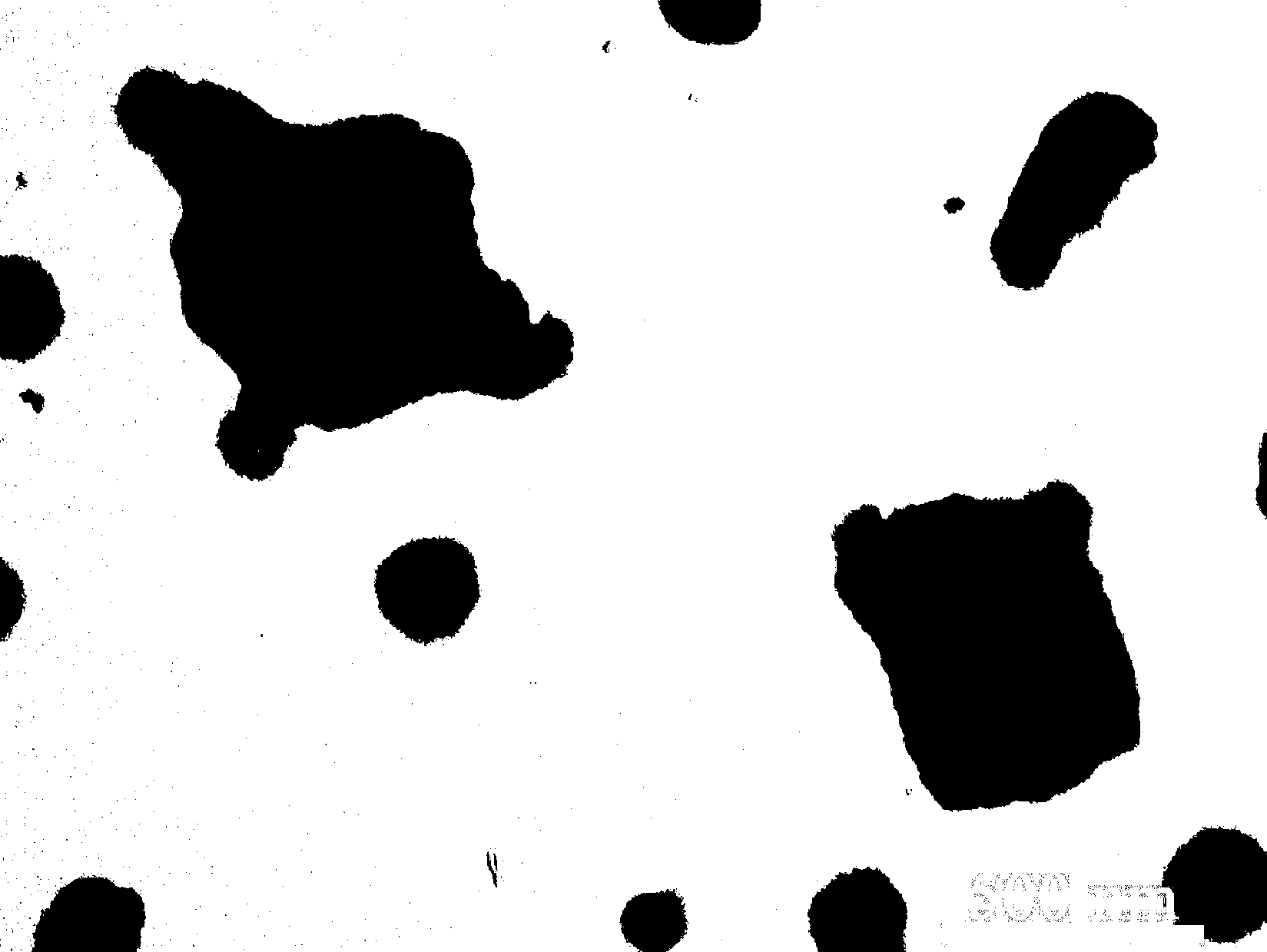

Image

Examples

Embodiment 1

[0022] Example 1: 980 mg of N-vinylcaprolactam, 20 mg of methacrylic acid, 20 mg of sodium lauryl sulfate and 25 mg of sodium bicarbonate were dissolved in 100 mL of water. Dissolve 40 mg of N,N’-bis(acryloyl)cystamine as a cross-linking agent in 2 mL of dimethyl sulfoxide, and transfer it to the reaction system after fully dissolving. Keeping the stirring speed at 200 rpm and nitrogen atmosphere, after raising the reaction temperature to 60-80 °C, 25 mg of potassium persulfate was added quickly, and the polymerization reaction was initiated immediately. After 6 h, the reaction was stopped and slowly cooled to room temperature under nitrogen atmosphere. After the reaction, use dialysis to remove unreacted monomers, linear polymers and other impurities, and freeze-dry to obtain a phase transition temperature of 37.6 under physiological conditions (pH 7.4, 0.15 M NaCl). o C's degradable environment-responsive polymer nanohydrogels.

Embodiment 2

[0023] Example 2: 970 mg of N-vinylcaprolactam, 30 mg of methacrylic acid, 20 mg of sodium lauryl sulfate and 25 mg of sodium bicarbonate were dissolved in 100 mL of water. Dissolve 40 mg of N,N’-bis(acryloyl)cystamine as a cross-linking agent in 2 mL of dimethyl sulfoxide, and transfer it to the reaction system after fully dissolving. Keeping the stirring speed at 200 rpm and nitrogen atmosphere, after raising the reaction temperature to 60-80 °C, 25 mg of potassium persulfate was added quickly, and the polymerization reaction was initiated immediately. After 6 h, the reaction was stopped and slowly cooled to room temperature under nitrogen atmosphere. After the reaction, use dialysis to remove unreacted monomers, linear polymers and other impurities, and freeze-dry to obtain a phase transition temperature of 40.0 under physiological conditions (pH 7.4, 0.15 M NaCl). o C's degradable environment-responsive polymer nanohydrogels.

Embodiment 3

[0024] Example 3: 960 mg of N-vinylcaprolactam, 40 mg of methacrylic acid, 20 mg of sodium lauryl sulfate and 25 mg of sodium bicarbonate were dissolved in 100 mL of water. Dissolve 40 mg of N,N’-bis(acryloyl)cystamine as a cross-linking agent in 2 mL of dimethyl sulfoxide, and transfer it to the reaction system after fully dissolving. Keeping the stirring speed at 200 rpm and nitrogen atmosphere, after raising the reaction temperature to 60-80 °C, 25 mg of potassium persulfate was added quickly, and the polymerization reaction was initiated immediately. After 6 h, the reaction was stopped and slowly cooled to room temperature under nitrogen atmosphere. After the reaction, use dialysis to remove unreacted monomers, linear polymers and other impurities, and freeze-dry to obtain a phase transition temperature of 44.2 under physiological conditions (pH 7.4, 0.15 M NaCl). o C's degradable environment-responsive polymer nanohydrogels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com