Fluorescent block-grafted copolymer with temperature sensitivity and preparation method and application thereof

A technology of graft copolymer and graft polymer, which is applied in the field of fluorescent block graft copolymer and its preparation, can solve the problems of regulation performance, uneven particle size distribution of spheres, and large steric hindrance of the inner core, etc., and achieve reaction Mild conditions, high conversion rate, and improved fluorescence response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

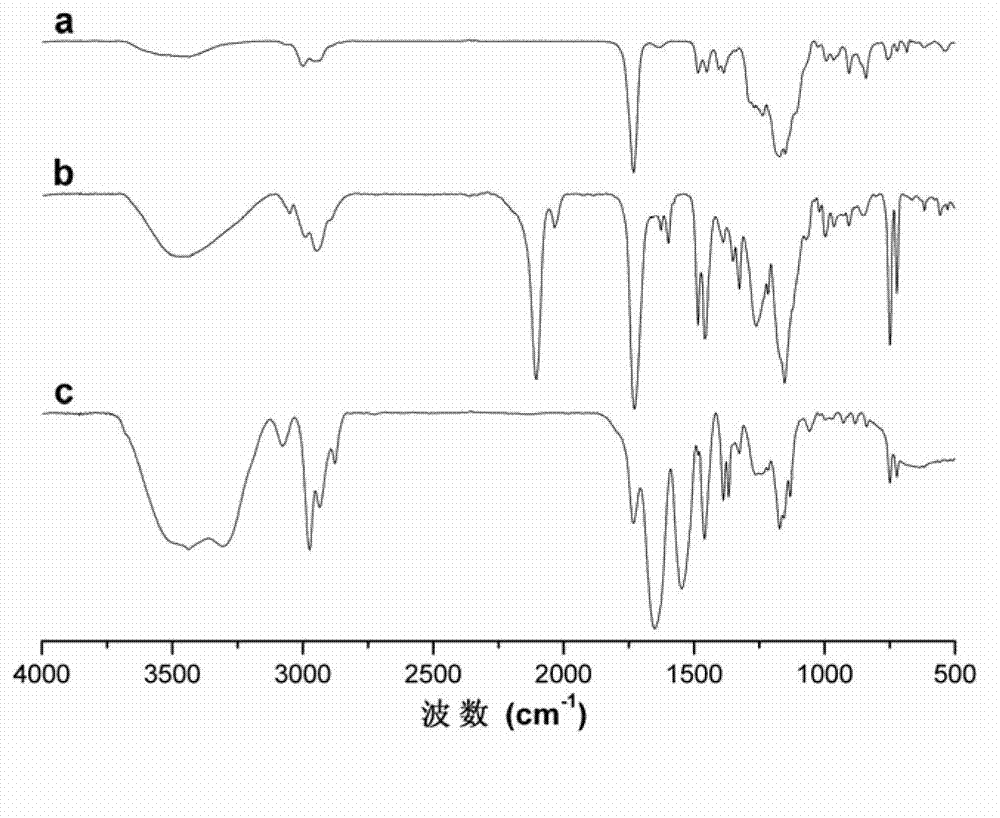

[0051] Embodiment 1: PCEMA-b-(PGMA-g-PNIPAM) and its preparation

[0052] (1) Preparation of PCEMA-b-PGMA: 6.32g of fluorescent functional group monomer carbazole ethyl methacrylate (CEMA), 4.92g of glycidyl methacrylate (GMA), 0.111g of initiator 2-bromoisobutyl Ethyl acetate, 0.081g cuprous bromide, 0.025g cuprous bromide and 14mL anisole were added to a 50mL single-port reaction bottle and the bottle mouth was sealed. 0.216g catalyst PMDETA and continue through three cycles once, put it in an oil bath at 65°C for 4 hours, freeze it with liquid nitrogen and dilute it with dichloromethane, then stir and oxidize it for 1 hour, remove the catalyst through neutral alumina, concentrate at room temperature for 30 minutes and then precipitate In 150mL of n-hexane, filter and evaporate the solvent, take the residue and dissolve it with 7mL of tetrahydrofuran and precipitate it with 200mL of n-hexane and circulate it twice, then take the precipitate and dry it under vacuum at room te...

Embodiment 2

[0067] Embodiment 2: PCEMA-b-(PGMA-g-PDNIPAM) and its preparation

[0068] (1) Preparation of PCEMA-b-PGMA: same as step (1) of Example 1;

[0069] (2) Preparation of PDNIPAM: 7.46g of temperature-sensitive monomer N,N-diisopropylacrylamide, 0.28g of chain transfer agent S-dodecyl-S'-(α-methyl-α "-propargyl isopropionate) trisulfide, 0.014g initiator AIBN and 14mL dioxane were added to a 25mL single-necked flask filled with argon and sealed well, after three cycles of gas blowing-freezing-thawing , placed in an oil bath at 75°C for 7 hours, then stopped the reaction in an ice-water bath, distilled under reduced pressure at 45°C to remove most of the dioxane and precipitated in 200mL of cold ether, took the precipitate, dried it at 25°C and dissolved it in 4mL Precipitate in 200mL cold diethyl ether (repeat this operation 3 times), take the precipitate, and dry it in vacuum at room temperature to obtain 5.43g of PDNIPAM;

[0070] The structural formula of PDNIPAM is as follow...

Embodiment 3

[0079] Embodiment 3: PCEMA-b-(PGMA-g-PmPEGMA) and its preparation

[0080] (1) Preparation of PCEMA-b-PGMA: 7.02g of fluorescent functional group monomer carbazole ethyl methacrylate (CEMA), 6.85g of glycidyl methacrylate (GMA), 0.166g of initiator 2-bromoisobutyl Acetate methyl ester, 0.145g cuprous bromide, 0.02g cuprous bromide and 20mL anisole were added to a 50mL single-port reaction bottle, and the bottle mouth was sealed. 0.086g catalyst PMDETA and continue through three cycles once, placed in an oil bath at 70 ° C for 7 hours. Freeze in liquid nitrogen and dilute with dichloromethane, stir and oxidize for 1 h, remove the catalyst through neutral alumina, concentrate at room temperature for 30 min, and precipitate in 200 mL of n-hexane, dissolve the precipitate in 4 mL of tetrahydrofuran and precipitate in 200 mL of n-hexane (repeat the operation 3 times) Finally, take the precipitate and dry it under vacuum at room temperature to obtain 8.42g of fluorescent copolymer;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com