N-type diamond semiconductor monocrystal and production method thereof

A production method and diamond technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of easy change of diamond crystal structure, increase of crystal internal resistance, slow growth rate of single crystal, etc., to achieve thermal conductivity and heat dissipation. The effect of good performance, increased number of free electrons, and extended chip life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

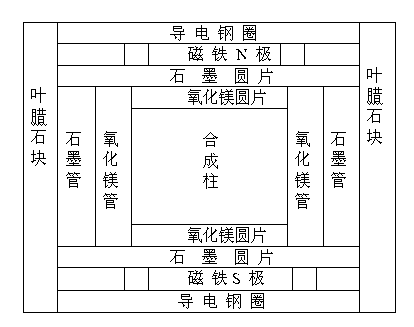

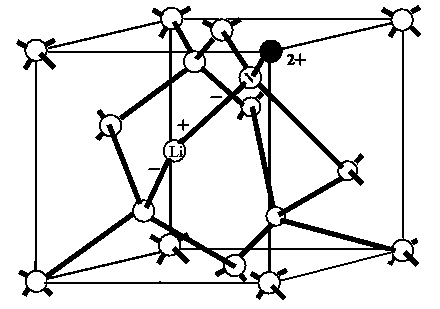

[0033] Example 1: A kind of N-type diamond semiconductor single crystal, its production method comprises the following steps:

[0034] Accurately weigh 50kg of high-purity natural graphite powder and 50kg of iron-nickel alloy powder (iron-nickel ratio 7:3), place them in a three-dimensional mixer with a volume of 100 liters, add 0.5kg of lithium nitride powder, nitrogen 0.5kg of beryllium powder, seal the feeding port tightly, start the mixer, and mix the mixture for 10 hours to obtain a uniform mixture; wherein the particle size of the graphite powder is less than 200 mesh, the degree of graphitization is >95%, and the content of non-carbon impurities is less than 30ppm; The particle size of iron-nickel alloy powder is less than 200 mesh;

[0035] Put the mixture into a latex bag, let it stand for 20 minutes to exhaust; tie the mouth of the bag tightly, put it into a cold isostatic press and pressurize it to 300MPa, release the pressure after holding the pressure for 5 minu...

Embodiment 2

[0039] Example 2: A kind of N-type diamond semiconductor single crystal, production method comprises the following steps:

[0040] Accurately weigh 40kg of high-purity natural graphite powder and 60kg of nickel-manganese-cobalt alloy powder, wherein the mass ratio of nickel, manganese, and cobalt is 70:25:5; place graphite powder and alloy powder in a V-shaped mixing material with a volume of 100 liters In the mixer, add 1 kg of lithium nitride powder and 1 kg of beryllium nitride powder to the mixer, seal the feeding port tightly, and then start the mixer, and mix the materials for 15 hours to form a uniform mixture; wherein the particle size of the graphite powder is less than 200 mesh, The degree of graphitization is >95%; the particle size of the iron-nickel alloy powder is less than 200 mesh.

[0041] Put the mixture into a latex bag, let it stand for 20 minutes to exhaust, tie the mouth of the bag tightly, put it into a cold isostatic press, pressurize to 300 MPa, hold...

Embodiment 3

[0044] Example 3: A kind of N-type diamond semiconductor single crystal, its production method comprises the following steps:

[0045] Accurately weigh 55kg of high-purity natural graphite powder, 45kg of iron-nickel alloy powder (iron-nickel ratio 7:3), put them in a three-dimensional mixer with a volume of 100 liters, and then add 2.5kg of lithium nitride powder, Beryllium nitride powder 2.0kg, after sealing the feeding port, open the mixer, mix the materials for 18 hours, and obtain a uniform mixture; wherein the particle size of the graphite powder is less than 200 mesh, the degree of graphitization> 95%, and the particle size of the iron-nickel alloy powder is less than 200 mesh.

[0046] Put the mixture into a latex bag, let it stand for 20 minutes to exhaust air, tie the mouth of the bag tightly, put it into a cold isostatic press and pressurize it to 200MPa, release the pressure after holding the pressure for 6 minutes, and take out the pressurized material; The bul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com