Titanium-calcium welding rod

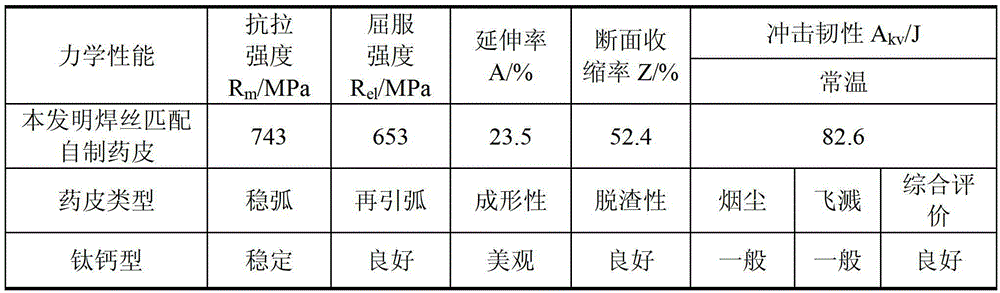

A technology of welding rod and titanium calcium, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of not having 2205 duplex stainless steel, etc., and achieve good arc stability, fine and beautiful weld shape, and spatter particles small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of above-mentioned titanium-calcium type electrode, concrete steps are as follows:

[0012] Step 1, the welding core is composed of the following components by weight percentage: 0.02%-0.03% carbon, 1.25%-1.6% manganese, 0.2%-0.3% silicon, 20%-23% chromium, 8.5%-9.5% nickel, molybdenum 2.5%~4.0%, nitrogen 0.15~0.20%, sulfur<0.01%, phosphorus<0.02%, the balance is iron, the weight percentage sum of the above components is 100%; Pure iron and industrial pure iron, ores containing C, Si, Mo, Cr, N, and nickel powder are put into the induction furnace together for smelting until the materials are all melted to form molten alloy steel, and its temperature reaches 1540 ° C. After the molten alloy steel is calm Stop heating, cool and exhaust for 10 to 20 minutes, then heat and refine for 15 to 25 minutes, and fill in argon and a small amount of nitrogen 5 minutes before the temperature of the molten alloy steel drops to 1540°C, so that the pressure in th...

Embodiment 1

[0033] Step 1, first put professional pure iron and industrial pure iron with a mass ratio of 1:1, ores containing C, Si, Mo, Cr, N, and nickel powder into an induction furnace for smelting, and the materials are all melted to form an alloy When the temperature of molten steel reaches 1540°C, stop heating when the molten alloy steel is calm, cool and exhaust for 15 minutes and then heat and refine for 20 minutes. When the air pressure reaches 250mmHg, when the temperature of the molten alloy steel is 1540°C, add Mn to the molten alloy steel and stir for 2 minutes, then tap the steel. After the surface of the molten alloy steel is calm, pour it evenly, and cool it to room temperature to obtain a steel ingot;

[0034] The steel ingot is peeled and forged into a billet. After cooling to room temperature, the black skin and cracks on the surface of the billet are removed and the header is cut off. Then, the billet is rolled into a wire rod with a diameter of 6.5mm by a rolling mill...

Embodiment 2

[0041] Step 1, first put professional pure iron and industrial pure iron with a mass ratio of 1:1, ores containing C, Si, Mo, Cr, N, and nickel powder into an induction furnace for smelting, and all the materials are melted to form an alloy When the molten steel temperature reaches 1540°C, stop heating when the molten alloy steel is calm, cool and exhaust for 10 minutes, then heat and refine for 15 minutes, and fill in argon and a small amount of nitrogen 5 minutes before the temperature of the molten alloy steel drops to 1540°C to make the pressure in the furnace Reach 350mmHg, when the temperature of the molten alloy steel is 1540°C, add Mn to the molten alloy steel and stir for 2 minutes, then tap the steel. After the surface of the molten alloy steel is calm, pour it evenly, and cool it to room temperature to obtain a steel ingot;

[0042] The steel ingot is peeled and forged into a billet. After cooling to room temperature, the black skin and cracks on the surface of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com