Modified Y-type molecular sieve and preparation method thereof

A molecular sieve and modification technology, used in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of zeolite structure damage, zeolite crystallinity decline and other problems, achieve less lattice defects, excellent stability, Good effect of structural hydrothermal stability and active hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the preparation method provided by the present invention, the phosphorus-containing substance in the phosphorus-containing exchange liquid is selected from one of orthophosphoric acid, phosphorous acid, pyrophosphoric acid, ammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, and aluminum phosphate. or more.

[0035] The ammonium-containing substance in the ammonium solution is selected from one or more of ammonium chloride, ammonium nitrate, ammonium carbonate, ammonium bicarbonate, ammonium oxalate, ammonium sulfate, and ammonium bisulfate.

[0036] The rare earth-containing substance in the rare earth-containing exchange liquid is selected from one or more of lanthanum oxide, cerium oxide, lanthanum nitrate, cerium nitrate, lanthanum chloride, cerium chloride, mixed rare earth nitric acid, and mixed rare earth chloride.

[0037] The inorganic acid for adjusting the pH value of the exchange solution is selected from one or more of hydro...

Embodiment 1

[0064] NaY zeolite is used as raw material for exchange with ammonium sulfate solution, the treatment conditions are: NaY molecular sieve (dry basis): ammonium sulfate: water = 1:1.0:8, sulfuric acid to adjust the pH value to 3.5, exchange at 85°C for 1 hour, and wash. Hydrothermal roasting treatment, roasting temperature 580°C, 100% steam roasting time 2h. Treat the post-baked sample with a solution containing rare earth, and the treatment conditions are: a baked molecular sieve (dry basis): rare earth chloride (according to RE 2 o 3 Calculated): water = 1: 0.042: 8, exchanged at 70°C for 1 hour, and washed with deionized water. Hydrothermal roasting treatment, roasting temperature 580°C, 100% steam roasting time 2h. Treat the sample after secondary roasting with a solution containing phosphoric acid and oxalic acid, and the treatment conditions are: secondary roasting molecular sieve (dry basis): phosphoric acid (according to P): oxalic acid (containing two molecules of cr...

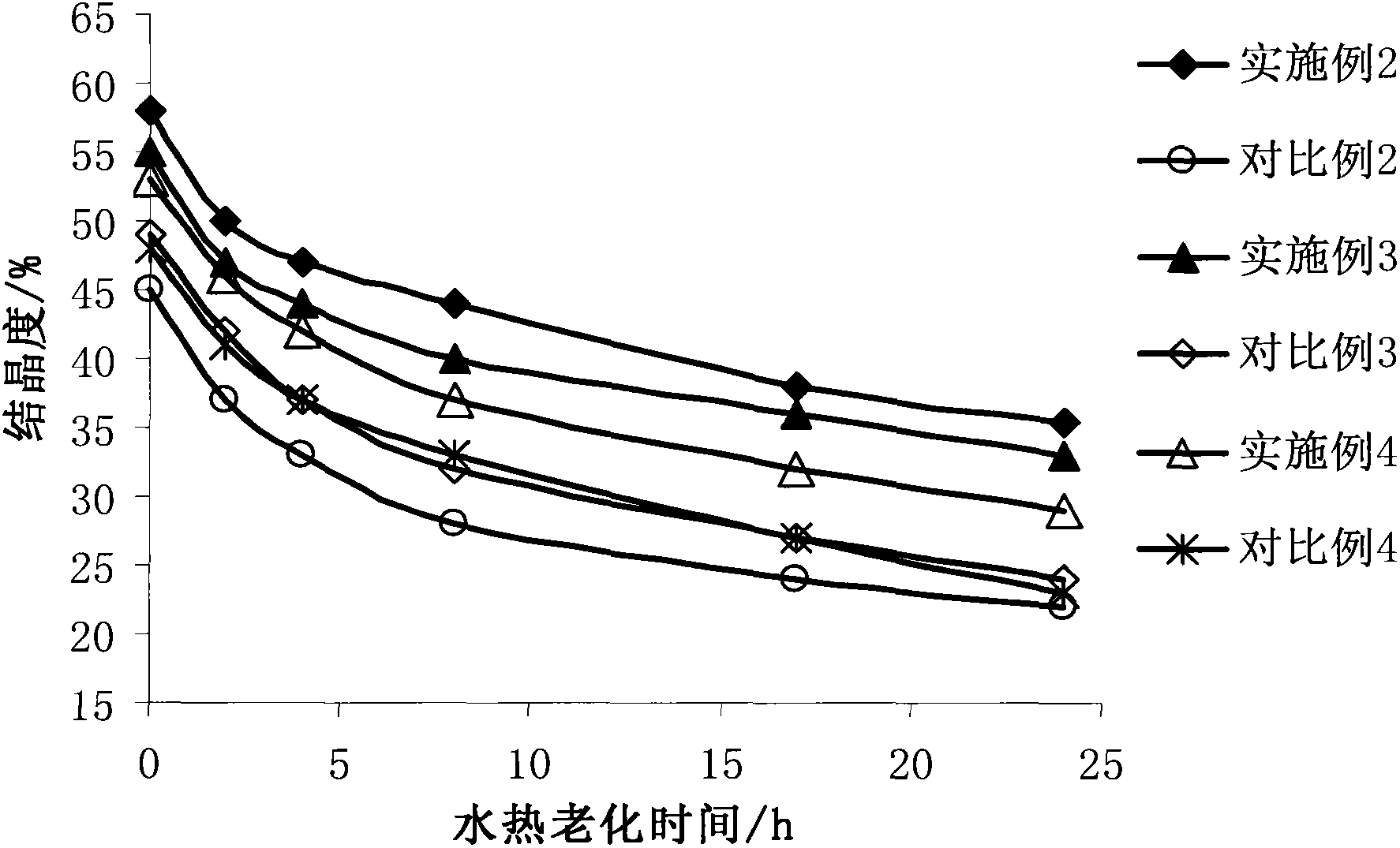

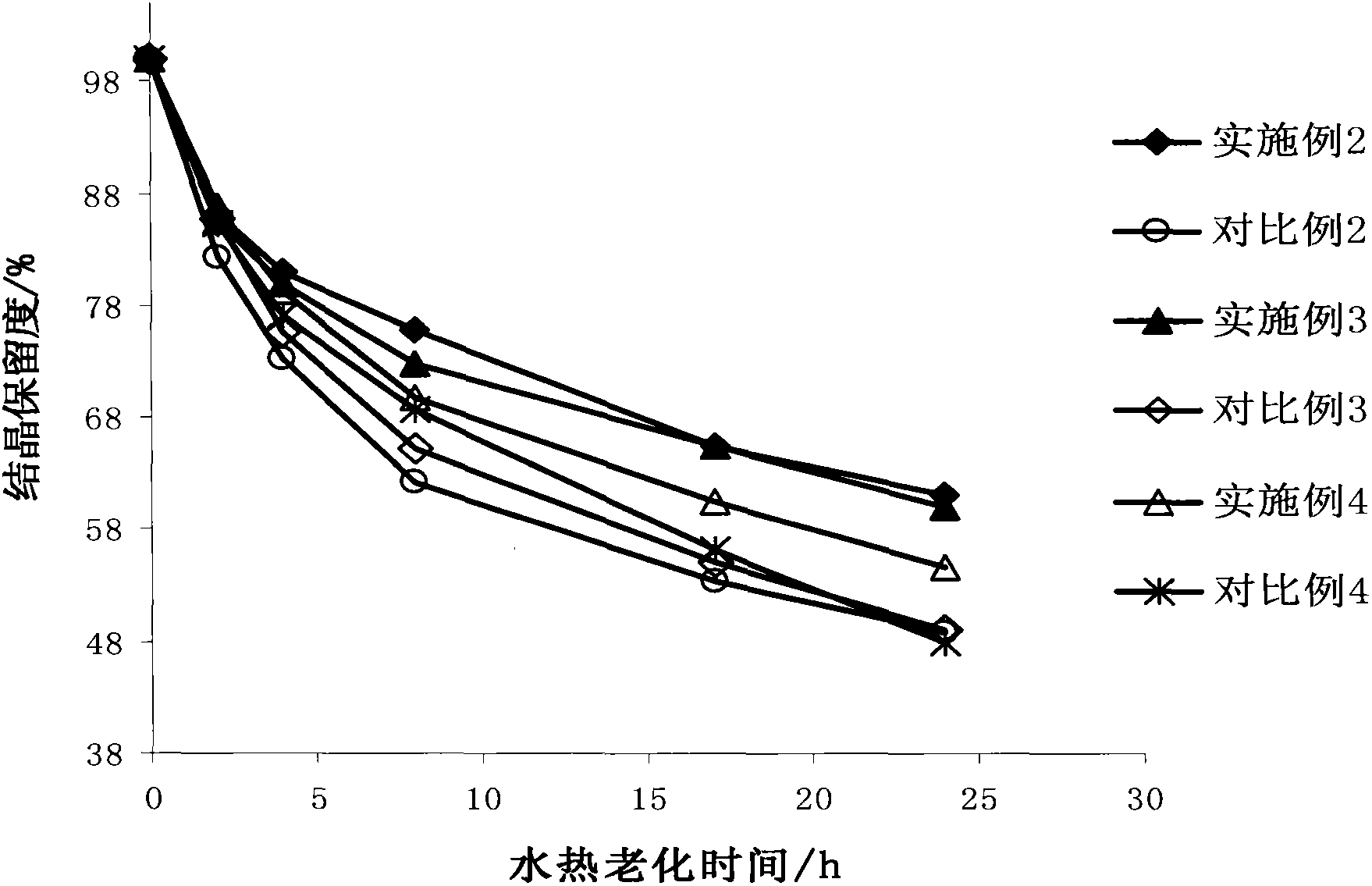

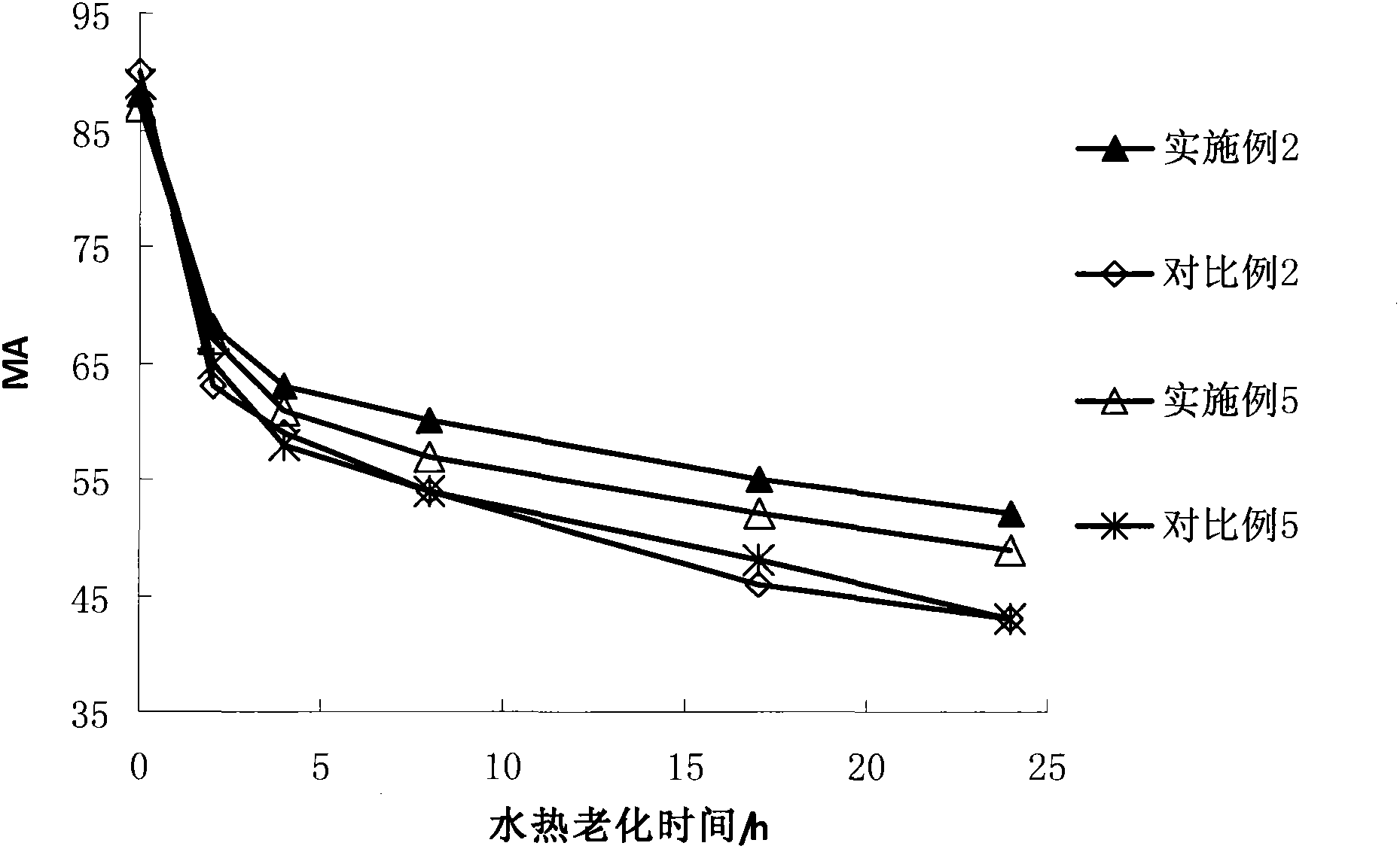

Embodiment 2

[0069]NaY zeolite is used as raw material for exchange with ammonium chloride solution, the treatment conditions are: NaY molecular sieve (dry basis): ammonium chloride: water = 1:0.8:8, hydrochloric acid to adjust the pH value to 4.0, exchange at 90°C for 1 hour, and wash. Hydrothermal roasting treatment, roasting temperature 550°C, 80% steam roasting time 2h. Treat the post-baked sample with phosphoric acid and fluorosilicic acid solution, the treatment conditions are: 1-baked molecular sieve (dry basis): phosphoric acid (according to P): fluorosilicic acid: water = 1: 0.01: 0.03: 8, hydrochloric acid to adjust pH2. 8. Exchange at 70°C for 1 hour, filter; wash with deionized water. Hydrothermal roasting treatment, roasting temperature 550°C, 70% steam roasting time 2h. Treat the sample after second roasting with a solution containing rare earth, and the treatment conditions are: second roasting molecular sieve (dry basis): rare earth chloride (according to RE 2 o 3 Calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com