Composite bulletproof flashboard and preparation method and application thereof

A technology of bulletproof inserts and laminates, applied in protective equipment, chemical instruments and methods, offensive equipment, etc., can solve the problems of ceramic plate fragmentation, impact on bulletproof effect, bullet penetration, etc., achieve light weight and improve bulletproof survivability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

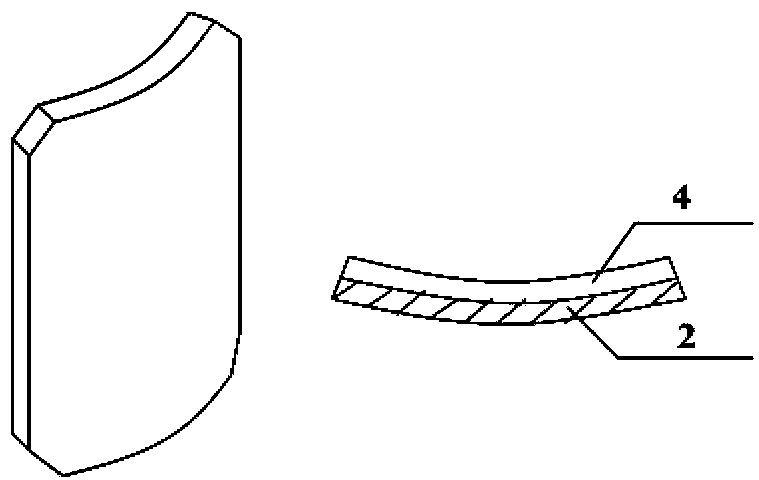

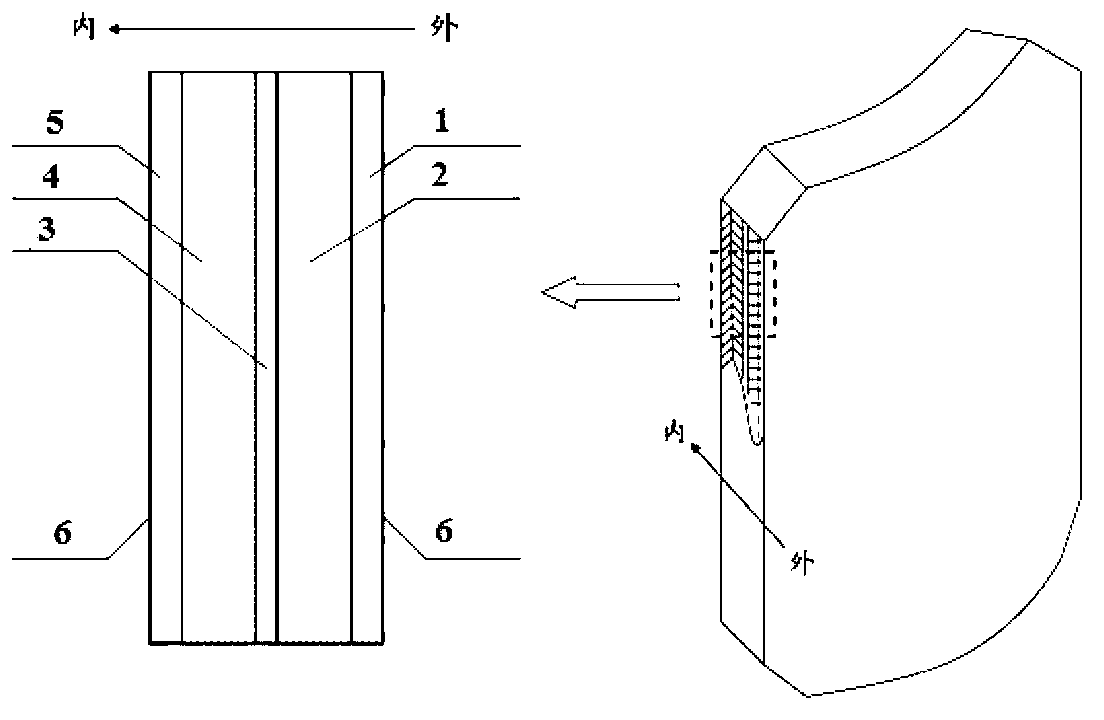

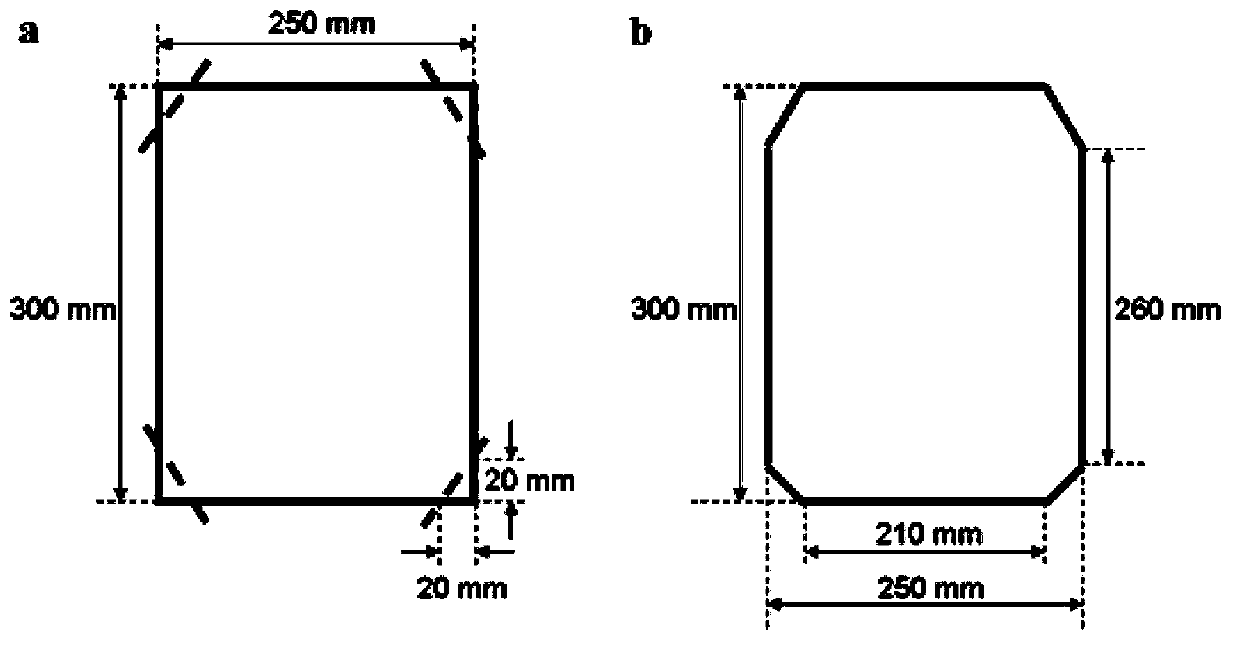

[0033] First set the areal density to 200g / m 2 The para-aramid fiber woven fabric is cut into two pieces of cloth with a size of 250×300mm to be used as the protective layer and the middle layer respectively, and then the epoxy resin and the vinyltriamine curing agent are mixed according to the mass ratio of 4:1 It is made into an adhesive, which is sequentially applied to para-aramid fiber woven fabric, silicon carbide ceramic plate (thickness 10mm), para-aramid woven fabric, ultra-high molecular weight polyethylene non-weft laminated board (area density 7kg / m 2 , the weight of the adhesive film accounts for 8% of the total weight of the laminate, and the material of the adhesive film is polyvinyl acetal), polyurethane foam material (area density 0.09kg / m 2 ) surface coated with adhesive and bonded sequentially, then clean the adhesive around the bulletproof board and the excess para-aramid woven fabric, and then cover the outermost layer with a layer of Oxford cloth with adh...

Embodiment 2

[0045] First set the areal density to 300g / m 2 The para-aramid fiber woven fabric is cut into two pieces of cloth with a size of 250×300mm to be used as the protective layer and the middle layer respectively, and then the epoxy resin and the vinyl triamine curing agent are mixed according to the mass ratio of 3:1 It is made into an adhesive, which is sequentially applied to para-aramid fiber woven fabric, boron carbide ceramic plate (thickness 5mm), para-aramid woven fabric, ultra-high molecular weight polyethylene non-weft laminated board (area density 10kg / m 2 , the weight of the adhesive film accounts for 15% of the total weight of the laminate, and the material of the adhesive film is polyethylene), polyurethane foam material (area density 1.5kg / m 2 ) surface coated with adhesive and bonded sequentially, then clean the adhesive around the bulletproof board and the excess para-aramid woven fabric, and then cover the outermost layer with a layer of Oxford cloth with adhesive...

Embodiment 3

[0057] First set the areal density to 400g / m 2 The para-aramid fiber woven fabric is cut into two pieces of cloth with a size of 250×300mm to be used as the protective layer and the middle layer respectively, and then the epoxy resin and the vinyl triamine curing agent are mixed according to the mass ratio of 2:1 It is made into an adhesive, which is sequentially applied to para-aramid fiber woven fabric, alumina ceramic plate (thickness 8mm), para-aramid woven fabric, ultra-high molecular weight polyethylene non-weft laminated board (area density 12kg / m 2 , the weight of the film accounts for 20% of the total weight of the laminate, and the material of the film is polypropylene), polyurethane foam material (area density 1.8kg / m 2 ) surface coated with adhesive and bonded sequentially, then clean up the adhesive around the bulletproof board and the excess para-aramid woven fabric, and then wrap a layer of Oxford cloth on the outermost layer as a whole (the temperature resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com