Method for removing olefin in aromatic hydrocarbon by M-SBA-15 type mesoporous molecular sieve

A M-SBA-15, mesoporous molecular sieve technology, applied in the direction of chemical change purification/separation, etc., can solve problems such as hindering petrochemical applications, weak surface acidity, etc., to avoid frequent switching operations of reaction and regeneration, small environmental impact, Avoid the effect of landfill disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of Al-SBA-15 Molecular Sieve Catalyst

[0030] According to the molar ratio of raw materials P123:Al 2 o 3 :SiO2 2 :HCl:H 2O is calculated as 1:3.1:62.5:300:10000, weigh 20 grams of P123, mix with the calculated amount of distilled water and hydrochloric acid, stir and mix at 40°C for 1.0 hour, add 1.3 grams of monohydrate alumina and continue to stir and mix for 1.0 hour Then, add 45.0 grams of tetraethyl orthosilicate and continue stirring and mixing for 5.0 hours; crystallization reaction at 100°C and autogenous pressure for 48 hours, filter, wash, dry at 120°C for 5 hours, and roast at 550°C for 5.0 hours to remove The template agent was removed to obtain 13.5 grams of Al-SBA-15 molecular sieve catalyst powder, which was extruded and crushed to obtain 20-40 mesh catalyst particles, which were designated as CAT-1.

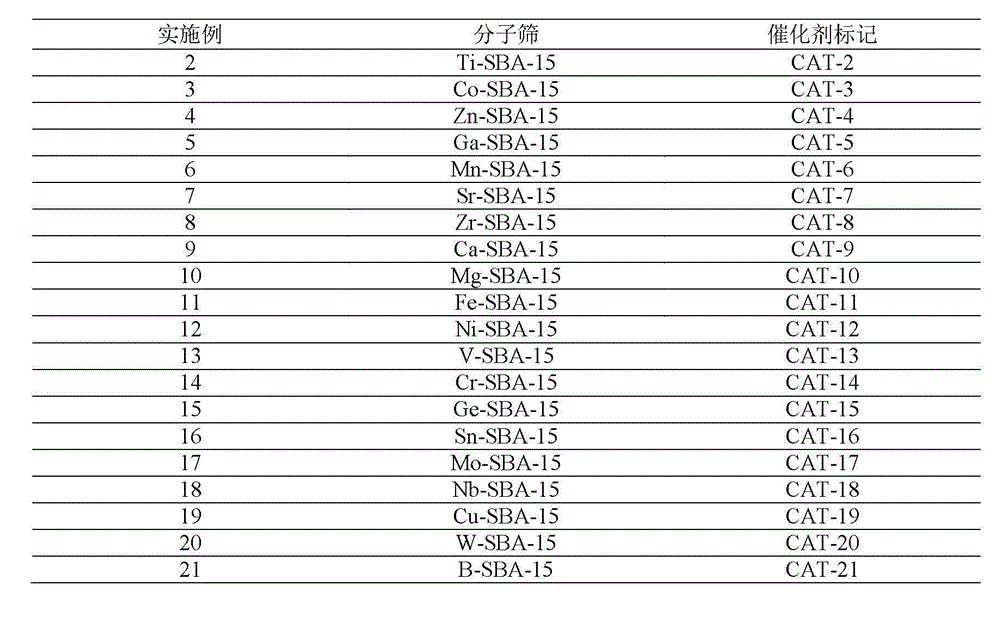

Embodiment 2~21

[0032] Using the same synthesis method as in Example 1, the difference is that the three-block polymer P123 is used as a template, and butyl titanate, cobalt nitrate, zinc nitrate, gallium nitrate, manganese nitrate, strontium nitrate, zirconium nitrate, nitric acid Calcium, magnesium acetate, iron nitrate, nickel nitrate, vanadium nitrate, chromium nitrate, germanium nitrate, tin nitrate, molybdenum nitrate, niobic acid, copper nitrate, tungstic acid, boric acid as precursors of the substituting element M, according to P123:MO n / 2 :SiO2 2 :HCl:H 2 O is 1:6.25:62.5:300:10000 molar ratio of raw materials to synthesize M-SBA-15 molecular sieve powder containing substituting elements. After extruding and crushing, 20-40 mesh catalyst particles are obtained, which are listed in Table 1.

[0033] Table 1

[0034]

Embodiment 22~36

[0036] Carry out loading modification to the Al-SBA-15 type molecular sieve catalyst of embodiment 1 and prepare composite solid acid catalyst

[0037] The 20-40 mesh Al-SBA-15 molecular sieve particles prepared in Example 1 are used in the following (1)-(14) operations for preparing supported catalysts:

[0038] (1) 10 grams of the Al-SBA-15 molecular sieve obtained in Example 1 was impregnated at room temperature for 24 hours with 100 milliliters of phosphoric acid aqueous solution with a concentration of 0.143 mol / L, followed by drying at 110°C for 3 hours and calcination at 400°C3 hours, get P 2 o 5 The P / Al-SBA-15 composite solid acid catalyst with a loading of 10.0wt% is referred to as CAT-22 catalyst (Example 22).

[0039] (2) Dissolve 5.0 grams of boric acid in 30 grams of acetone solvent, dissolve evenly, add the above-mentioned Al-SBA-15 molecular sieve, stir at room temperature for 15 minutes, heat to evaporate the acetone, and dry at 120°C for 3 hours to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com