Method for preparing nano zinc oxide by taking nano spherical polyelectrolyte brush as microreactor and application of nano zinc oxide

A polyelectrolyte brush and nano-zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., to achieve excellent dispersion and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Nanospherical Polyelectrolyte Brushes by Thermal Emulsion Polymerization

[0024] Put 22.3 ml of polybutadiene microsphere emulsion (the content of polymer microspheres is 3.0 g), 180 ml of deionized water, and 0.06 g of potassium persulfate into a 500 ml three-neck flask, among which, the dynamic light scattering (DLS) test results It is shown that the hydrodynamic diameter of the polybutadiene microsphere is 130 nanometers, and the solid content of the emulsion is about 13.4%. After fully dissolving under stirring, pump nitrogen gas 3 to 5 times, and control the rotation speed at 300 rpm. After the temperature stabilized to 80°C, maintain the temperature and rotation speed and continue stirring for half an hour. Dissolve 3.0 grams of acrylic acid monomer in 90 milliliters of deionized water, quickly drop it into a three-necked flask under nitrogen, and continue the reaction for 1 hour to obtain a nano-spherical polyelectrolyte brush emulsion. After di...

Embodiment 2

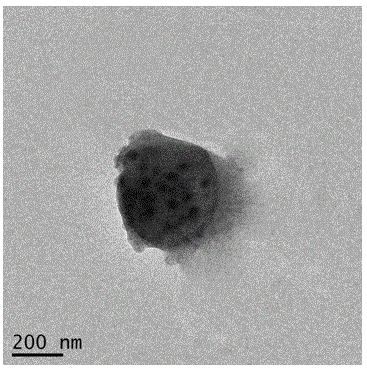

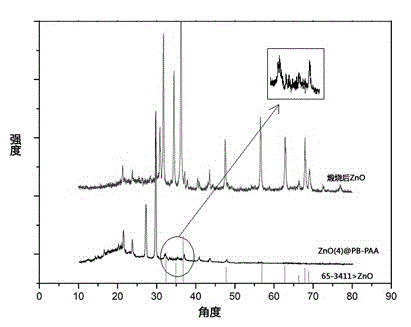

[0026] Preparation of nano-zinc oxide using nano-spherical polyelectrolyte brushes as nano-reactors

[0027] Get 100 milliliters of nano-spherical polyelectrolyte brush emulsions obtained in Example 1 in a 250 milliliter three-necked flask, dissolve 0.125 grams of zinc nitrate hexahydrate in 20 milliliters of deionized water, and slowly add it dropwise to the flask at a rate of 1 second / drop, and continue to stir for one hour at a stirring speed of 300 rpm. Pump nitrogen gas for 3 to 5 times. After the temperature stabilizes to 80°C, dissolve 0.13 g of hexamethylenetetramine in 20 ml of deionized water and add it dropwise to a three-necked flask under a nitrogen atmosphere at a rate of 2 seconds / drop. Maintain the temperature and rotating speed to continue the reaction for 2 hours, and finally obtain nano-zinc oxide loaded on the nano-spherical polyelectrolyte brush, and use a dialysis bag with a molecular weight cut-off of 14000 g / mol to dialyze out small molecular impuritie...

Embodiment 3

[0029] Preparation of high-content nano-zinc oxide using nano-spherical polyelectrolyte brushes as nano-reactors

[0030]Get the nano-spherical polyelectrolyte brush emulsion 100 milliliters that the load of embodiment 2 gained has nano-zinc oxide and 250 milliliters there-necked flasks, then 0.125 gram zinc nitrate hexahydrates are dissolved in 20 milliliters of deionized waters, and slowly drop into flasks, drop The acceleration is 1 second / drop, and the stirring is continued for one hour, and the stirring speed is constant at 300 revolutions / minute. Pump nitrogen gas for 3 to 5 times. After the temperature stabilizes to 80°C, dissolve 0.13 g of hexamethylenetetramine in 20 ml of deionized water and add it dropwise to a three-necked flask under a nitrogen atmosphere at a rate of 2 seconds / drop. Maintain the temperature and rotation speed to continue the reaction for 2 hours, and finally obtain nano-zinc oxide supported on nano-spherical polyelectrolyte brushes. Continue to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrodynamic diameter | aaaaa | aaaaa |

| Hydrodynamic diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com